Numerical control lathe is also called CNC lathe or CNC turning machine, that is, computer digital control lathe, which is a kind of numerical control equipment with larger usage and wider coverage. The CNC turning machine is an electromechanical integrated product that integrates many technologies such as machinery, electricity, hydraulics, pneumatics, microelectronics and information. The equipment can process your material from start to finish and provide you with the finishing parts you need.

In the past, manual lathes required a lot of labor and time to produce high-quality parts, but nowadays, using advanced CNC turning machine to provide customized CNC machining services can achieve the same purpose. These lathes have become commonly used manufacturing tools, have replaced traditional old lathes, and are used by various industries for manufacturing needs.

If you are looking for CNC lathes or CNC turning services, then knowing more about lathes can help you choose the ideal CNC service provider to meet your needs.

What is a CNC Turn Machine?

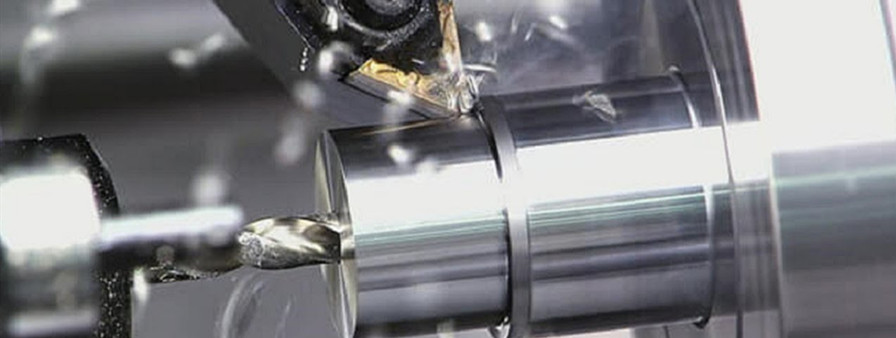

In short, a CNC lathe is a reinvented manual lathe that uses computer control to rotate the workpiece, and uses sharp cutting tools and drills to cut away excess material to make symmetrical parts.

The CNC lathe rotates the workpiece along a single vertical axis or horizontal axis while feeding the cutting tool into the part to form a specific shape.

CNC lathes are programmed by machinists to perform detailed operations such as cutting, metal spinning, metal processing, thermal spraying, etc.

The CNC lathe has good rigidity and high manufacturing accuracy. It can process parts that require high shape accuracy such as bus straightness, roundness, and cylindricity.

CNC Lathe Types

CNC lathes can be divided into two types, namely vertical lathes and horizontal lathes.

1. Vertical CNC lathe

As the name implies, the spindle axis of the vertical CNC lathe or machine center is placed vertically, and the spindle is equipped with a milling cutter. Then the workpiece is rotated vertically to make the spindle cut at a specific angle.

Compared with horizontal CNC lathes, vertical lathes usually take up less space. These machines are also very suitable for manufacturing large and heavy workpieces.

The vertical design also helps the machine remain stable throughout the process, so that parts can be cut more accurately.

Because of this function, CNC vertical lathes (called CNC vertical lathes) are much more expensive than horizontal vertical lathes.

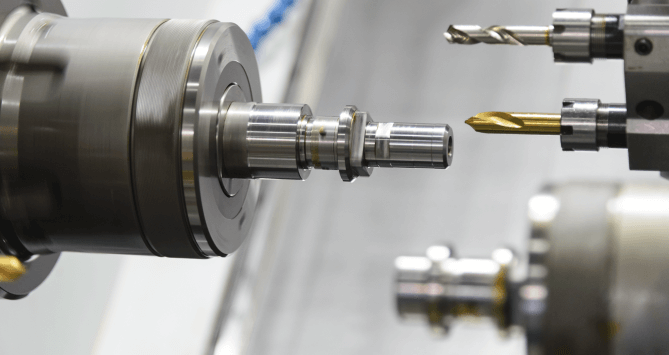

2. Horizontal CNC lathe

The tool configuration of the horizontal CNC lathe is installed horizontally. The workpieces on these tools rotate in a cylindrical shape, while the tools cut excess material.

Since the workpiece is fixed vertically on the chuck, these machines are ideal for processing lighter materials or metals.

Horizontal CNC lathes usually require more space because they require the workpiece to be placed vertically. This also makes them ideal for the production of small and medium-sized workpieces, which may also include forming flat surfaces.

Advantages of CNC Turning Machine

1. High accuracy and repeatability

If the CNC lathe is programmed correctly, it can usually produce 100% products accurately. They produce parts to improve accuracy to a greater extent. Provide good positioning accuracy and repeatability. Because of their accuracy and ability to reuse programs, they can provide higher quality.

2. Reduce costs

No need to manually process parts for you, but process the original parts into cnc machined parts manufactured according to drawings. These advanced lathes can help you save setup, reduce material waste costs and most importantly labor costs.

3. Easy to operate

Once you learn the CNC lathe, it will not be difficult to use. For example, because there are fewer fixtures, there is no need to use complex fixtures and fixtures in all areas, thereby reducing actual storage requirements. Since no complicated fixtures and fixing devices are required, the cost of the mold is reduced. After the passed inspection, the inspection of subsequent parts is reduced. Advanced machine control and programming functions make complex machining operations easier.

4. Shorten time

The use of CNC lathes can effectively reduce the time required to produce furniture. CNC lathes enable operators to make changes or improvements with less delay or expense. Reduce waste, because errors due to operator fatigue, interruptions and other factors are unlikely to occur. Improve production plans because they can usually perform work in a setup that usually requires multiple conventional machines. Except for occasional maintenance hours, CNC lathes can be used 24 hours a day, 365 days a day.

5. Low surface roughness

When the material allowance on the workpiece and the tool angle allow, the surface roughness depends on the cutting speed, while the feed speed of the ordinary lathe is a constant speed, and the cutting speed is different for different diameters, such as the CNC lathe with constant cutting function Processing, and the same linear speed can be used to face cylinders of different diameters, to ensure that the surface roughness value is small and the surface roughness processed on different surfaces, the smaller the surface roughness and the use of the same, the feed speed is small, the surface is rough The speed is large, the use feed speed is large, and the variability is very good.

6. Save manpower

One person can program many CNC lathes and then supervise them, usually allowing them to work on their own. Sometimes, the cutting tool needs to be replaced only occasionally.

7. Eliminate human error

The main problems in part production and manufacturing are accuracy and errors. Thanks to the precise CNC machining technology, the accuracy obtained by CNC lathes and CNC milling machines is fully satisfied, and they are very suitable for industries that require high-precision machining parts.

Final thoughts

In summary, CNC lathes are far ahead in terms of accuracy and utilization, and have many advantages over traditional lathes or lathes.

Therefore, now that you have mastered the necessary information about CNC lathes, it will help you choose the best CNC machining supplier next time you have machining needs. Welcome to contact SANS Machining, we will serve you wholeheartedly. SANS is a CNC precision machinery factory that provides excellent CNC milling services, CNC turning services, grinding and EDM services for major industries.