Author Archives: sansmachining

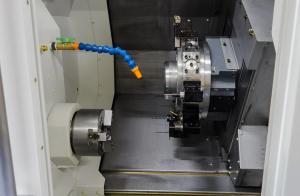

How To Improve Surface Finish In CNC Turning

Explores proven strategies and practices that machinists and engineers can apply to enhance surface quality [...]

Jul

Soft Tooling vs. Hard Tooling In Manufacturing: Key Differences, Advantages, And Applications

This article explores the characteristics, benefits, and limitations of both soft and hard tooling, as [...]

Jul

Tapped Hole vs Threaded Hole In Machining: Understanding The Differences And Applications

Explores the differences between tapped holes and threaded holes, their creation methods, applications, and design [...]

Jul

Preventing Part Movement During CNC Machining

Part movement is one of the most common causes of dimensional inaccuracy, surface defects, tool [...]

Jul

Fixture Plates, Tooling Plates, And Modular Fixtures: Foundations Of Precision In CNC Machining

These tooling components form the foundation of secure and repeatable setups, allowing parts to be [...]

Jul

Understanding SFM in CNC Machining: A Key To Speed, Efficiency, And Tool Life

This article offers a comprehensive explanation of what SFM is, why it matters, how to [...]

Jul

Step Turning In CNC Machining: Process, Tooling, And Key Applications

This article explores the step turning process in depth—covering its working principles, tooling requirements, benefits, [...]

Jun

Hard Turning VS Grinding

Grinding and hard turning are two technologies that control critical dimensions, and each has advantages [...]

Jun

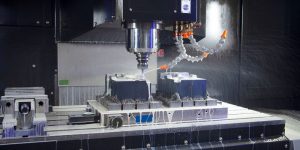

The Future of Manufacturing: How CNC Machining Drives Precision and Innovation

As manufacturing embraces digital transformation and Industry 4.0, this article explores how CNC machining is [...]

Jun

CNC Turning And Its Application In The Automotive Industry

This article explores how CNC turning is applied in the automotive sector, highlighting its advantages, [...]

Jun

CNC Machining Helps Electric Vehicles Move Towards The Future

As the core force of modern manufacturing, CNC machining technology is providing strong support for [...]

Jun

Sustainability In Machining: Building A Greener Future for Manufacturing

Through innovative technologies, smarter material choices, and improved waste management, machining is evolving to meet [...]

Jun

Mastering Bevel Edge Machining: A Comprehensive Overview

Among the many types of edge treatments, beveling is one of the most commonly used [...]

Jun

The Power Of Custom Manufacturing In Modern Industry

In an age where flexibility, speed, and product differentiation are vital, custom manufacturing has emerged [...]

Jun

The Role of IoT In CNC Machining Manufacturing

We explore IoT’s impact on CNC machining, how IoT is revolutionizing CNC machining, its key [...]

May

How To Select The Right Plastic Material For CNC Machining

Selecting the right plastic for CNC machining is critical to ensuring optimal performance, cost-effectiveness, and [...]

May

Internal Support Fixtures vs. External Clamping Fixtures in CNC Machining

Internal support fixtures and external clamping fixtures, as important components of the clamping system, significantly [...]

May

Angle Milling In Machining: Processes, Tools And Applications

Angle milling has been widely and deeply applied, providing a practical solution to the high-precision [...]

May