Automation is one of the main driving forces of CNC manufacturing. As automated manufacturing continues to step into the industrial field and new inventions come, CNC programming will play an important role.

CNC programmers operate a computer numerical control machine to cut materials such as metals and plastics to make things like airplanes or household appliances. In the simplest terms, CNC programmers use codes and software to tell the machine what to cut. In addition to the initial programming mechanism, they also troubleshoot and improve existing software and code. They use blueprints to ensure precise directions and make improvements with engineers.

The industry is gradually realizing the importance of CNC programming. From now to 2026, the average annual growth rate is 16%, and opportunities are multiplied. The employment gap is getting wider because many people still don’t understand this kind of gold mine. So today we will introduce what CNC programmers are and what they do.

What Should A CNC Programmer Study?

Employers usually prefer to hire CNC programmers with at least five years of experience. They should have communication, critical thinking and problem-solving skills, system analysis and mathematical skills, and knowledge of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. CNC machine tools use a different dialect of a programming language called “G code”.

They use several types of CNC software to write instructions. There are many types of CNC software, but the following are the most common:

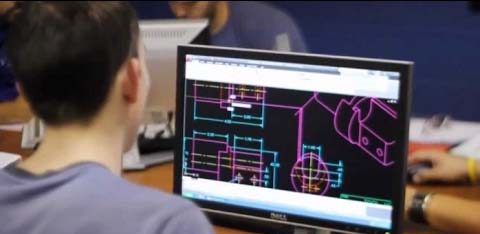

CAD software: used to create designs and blueprints for parts. CAD stands for “Computer Aided Design”.

CAM software: used to generate CNC machine instructions (G code) from CAD engineering drawings. CAM stands for “Computer Aided Manufacturing”.

G-code editing and simulation software: software used for testing, simulation, optimization and editing of g-code in other ways.

CNC programmers use their software to create, test and modify CNC machine tool programs (also called part programs).

CNC programmers usually use plastic and metal materials, so knowledge and expertise in these areas will also help.

What Skills Should CNC Programmers Have?

In addition to proficient in using the software to be used, CNC programmers also need to have the following skills:

- Able to read and understand drawings and blueprints. This includes the ability to understand print size and tolerance information.

- Have an in-depth understanding of the different machines they are programming and their capabilities.

- Understand the different tools (cutter) used by the machine and the feed and speed of the cutter for various materials.

- Understand the workpiece fixing device used to fix the part during processing.

- Able to coordinate with purchasing managers to help manage raw material inventory.

- People who pay attention to details and have good mathematical and technical skills can become the best CNC programmers.

What Machines Do CNC Programmers Operate?

Conventional technologies: These technologies include drills, lathes and milling machines. The drill bit rotates on a fixed block of raw material and moves the drill bit. At the same time, the lathe moves sideways to mark the material where it should be cut. Finally, the milling machine uses a rotary cutting tool to remove unwanted raw material blocks from the output.

New technologies: These technologies include motors or chemical machinery and other cutting media. Innovative technologies are highly specialized and can be used to mass-produce specific types of materials. Some use lasers, oxygen, plasma or water jets to cut materials.

How Does CNC Programming Work?

Determine the sequence of machine operations and select the appropriate cutting tools required to process the workpiece into the desired shape.

Modify the program or tape to eliminate the error, and then retest the program to check whether the problem has been resolved.

Analyze work orders, drawings, blueprints, specifications, printed circuit board pattern films and design data to calculate dimensions, tool selection, machine speed and feed speed.

Write instruction sheets and cutter lists for the machine’s controller to guide the setting and coding of the CNC belt.

Observe the machine or perform computer simulation during the trial run to ensure that the program and the machine will operate normally and produce items that meet specifications.

Use computer-aided drawing software or drawing tools and graph paper to prepare the geometric layout from the graphic display.

CNC Programmer VS CNC Machinist vs. CNC Operator

The basis of CNC machining starts with a CNC programmer. Afterall, this is the person who develops the programs and instructions needed to operate CNC equipment! This professional may also set up, operate, or maintain equipment.

In order to create programs for CNC machinery, CNC programmers must be able to read blueprints and 3D computer designs in order to understand the specifications of any given part. The programmer must also perform calculations to determine how much material is needed, the speed at which it should be fed into the machine and cut, where certain patterns (ie holes) need to be placed in it, and so on. One of these important details is determined, and then CNC programmers encode these details into numbered sequential instructions for machine tools and CNC machinists to follow.

For many organizations, the roles of CNC mechanics and CNC operators are not much different. In fact, these two terms are sometimes used interchangeably. Machinists and operators usually have very similar responsibilities and obligations. Both roles involve setting up and running CNC machines to create and change products.

It is worth noting that there are subtle differences between CNC machinists and CNC operators. In this field, CNC operators are considered entry-level workers. On the other hand, CNC machinists tend to have more experience and advanced skills. In many organizations, CNC operators work under the guidance of CNC machinists.

To Sum Up

The manufacturing industry is developing. Modern manufacturing companies are adopting advanced systems and equipment controlled by computers, which are exactly what CNC machining does. CNC machining has changed the manufacturing world as we know it. It continues to improve and accelerate the development of the industry. With the increasing demand for speed, innovative and highly skilled workers are needed.