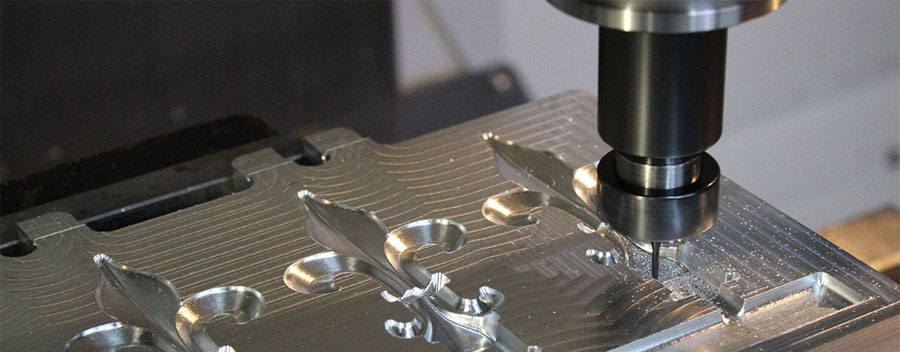

In today’s assembly workshops and manufacturing centers, CNC machine are one of the most popular equipment. Computer numerical control (CNC) equipment includes milling machines, lathes, drills, and almost all other machinery needed in the production workshop. CNC technology allows the machine to be programmed to perform multiple operations according to exact specifications. The same operation can be repeated, so that the manufacturer can produce goods produced using the exact same process every time, thereby improving cost-effectiveness and efficiency.

More and more manufacturers are looking for new and smaller components to maximize space utilization, shorten processing time, tighter tolerances, crazy fast turnarounds, and other benefits to ensure that consumers’ needs are met. This pressure will not take manufacturers engaged in precision machining out of the loop.

The introduction of automation has shown many manufacturers what can be done, and this continues to affect their expectations to achieve higher target levels of performance and productivity. The future of advanced automation will continue to develop. With the development of technology to meet the needs of manufacturers, customers continue to push the limits of processing speed and accuracy, leading to continuous innovation in the field of precision machining automation.

The Benefits Of CNC Automation In Machining

Compared with “traditional” machine tools that require a single operator, CNC automation has a wide range of advantages. These include:

Effectiveness

CNC machine tools have high precision, which can reduce the waste of each workpiece. Reducing waste can reduce production costs. Since their operation does not require human intervention, CNC machines can also be used throughout the day-CNC-equipped machines can work around the clock!

Speed

CNC machines combine several manufacturing steps in modern industrial processes. Improving efficiency can greatly reduce the time required to complete production. In addition, CNC machines perform a single action in the manufacturing process much faster than ordinary people.

Safety

Once the instructions are programmed, the CNC machine will run independently. Once the CNC program is started, the operator will not participate. This makes CNC automation an ideal technology for manufacturing processes involving corrosive or toxic substances, extremely high temperatures, and other factors that pose a danger to workers.

Consistency

Every day of the year, CNC automated machines can complete the same work in exactly the same way 24 hours a day. They only need occasional downtime for repairs and maintenance.

Complex

CNC machine tools can accurately follow all programming instructions down to the most important details. This enables manufacturers to manufacture products with increasing complexity and precision.

Capacity

CNC machines can continuously produce a large number of products, and the products are almost the same. In addition to machine failures or programming errors, CNC technology can also eliminate user errors. Conversely, because the machine runs longer and can handle more parts, the capacity increases.

Simple

One operator can supervise multiple CNC-equipped machines. Since the machine can perform actual cutting, punching, drilling or any other required manufacturing processes, the operator does not need to have high skills. This leads to lower labor costs.

CNC technology has some shortcomings, the most obvious of which is the potentially high cost of equipping the entire factory with CNC automation. Despite the high start-up cost, many CNC machines make up for their initial cost by reducing material waste, improving efficiency and avoiding human error. CNC automation provides long-term savings for manufacturers throughout the industry.

What Is The Future Of Automation?

CNC automation has just matured, and manufacturers are developing new and more effective methods of using this technology every year. Currently, research experts are trying to find a way to integrate CNC machine tools with advanced robotics technology and apply it to the entire industry. Robots for packaging and moving finished products. Such a breakthrough will simplify the manufacturing process.

Advanced automation solutions enable users to process micro and ultra-precision components with maximum repeatability and minimum manpower. The programming of automation equipment has become easier to use, and it provides extensive system integration across the entire processing line across multiple processing platforms.

Further networking between CNC machines will also be an important consideration for manufacturers. CNC automation has played a huge role in improving modern manufacturing. As market demand continues to drive the innovation of advanced precision machining solutions, the cost-effectiveness of these technologies and their ease of use in advanced automation make these technologies widely applicable to many manufacturing industries.