Author Archives: sansmachining

What Are The Significance And Advantages Of Non-standard Machine?

Traditional standardized equipment may not be able to meet the needs of enterprises, so non-standard [...]

Jan

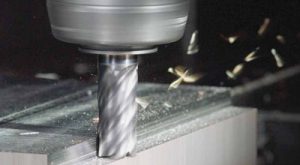

How To Reduce The Tool Radial Runout In CNC Milling?

The radial runout of the tool affects the machining accuracy, surface roughness, unevenness of tool [...]

Jan

高速加工101

高速加工(HSMまたはHSC)は、1990年代に急速に開発され、適用された高度な加工技術です。 [...]

How To Improve The Service Life Of Tungsten Steel Milling Cutter?

Tungsten steel milling cutter is a tool made of tungsten steel (hard alloy, also known [...]

Jan

Why Does CNC Precision Parts Machining Need Electroplating?

n the process of CNC parts machining, what is the effect of the surface treatment [...]

Dec

What Is Deburring And How To Remove Burrs From Metal Part?

The so-called burr is mainly a kind of extra metal chips generated at the processing [...]

Dec

Design Guidelines For CNC Machining

Avoiding common mistakes can help improve design, shorten run time, and possibly reduce final manufacturing [...]

Dec

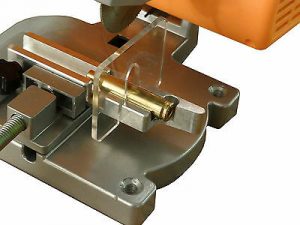

Design Points Of Special Fixtures

The fixture design is generally carried out in accordance with the specific requirements of a [...]

Dec

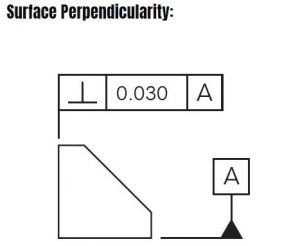

GD&T Perpendicularity

Surface perpendicularity is a tolerance used to control the perpendicularity between two 90° surfaces or [...]

Dec

What Should Be Paid Attention To In Aluminum CNC Machining?

Aluminum alloy CNC machining manufacturers summarize the process skills during the processing and the problems [...]

Dec

What Is The Standard For Testing Before CNC Machining?

before CNC machining what is the standard for testing? [...]

Dec

The Importance Of CNC Machining To The Robotics Industry

A basic method of manufacturing robotic parts is CNC machining. With so many possible functions, many [...]

Dec

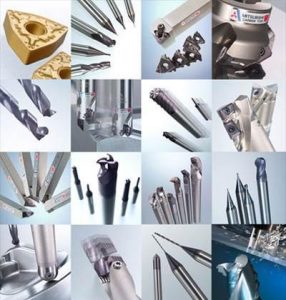

Processing Tools Used In CNC Machining

From drills and end mills to reamers, the selection of CNC machining tools is critical [...]

Dec

6061 VS 7075 Aluminum, Which One Is Better?

We will introduce the obvious differences between 6061 aluminum and 7075 aluminum from chemical composition, [...]

Dec

4 Common Process Methods Of Partial Electroplating

Based on daily work experience, several local electroplating process methods commonly used in electroplating are [...]

Dec

2 Factors Affecting The Quality Of Electroplating Layer

The quality of electroplated parts directly affects the overall quality of the equipment. The [...]

Dec

Different Types Of CNC Milling Operations

What are the types of CNC milling performed in the CNC machining workshop? Read this [...]

1 Comments

Dec

穴あけVSリーマVSボーリングVSホーニング、違いは何ですか?

穴あけは穴あけのプロセスですが、ボーリングは既存の穴の直径を拡大します。 リーマとホーニングは、既存の穴の表面仕上げと公差を改善するために使用されます。 次のセクションでは、穴あけ、リーマ加工、ボーリング、ホーニングの各プロセスの類似点と相違点について説明します。 [...]

Dec