Acrylic, also known as Plexiglas or PMMA (polymethyl methacrylate), is a transparent thermoplastic renowned for its clarity, durability, and versatility.

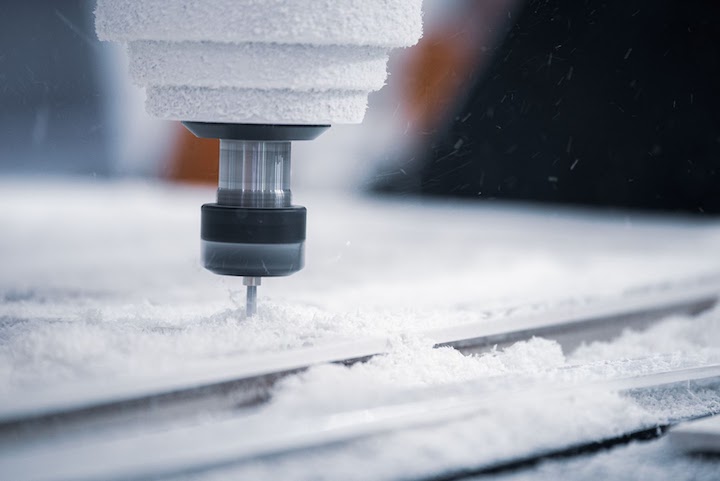

Acrylic (PMMA) is an ideal material due to its strength, toughness, and transparency. But relying on traditional processing techniques to cut acrylic can be a complex process: this material is very fragile, and any excessive force can cause unnecessary damage.

However, CNC machining provides a reliable method for safely manufacturing acrylic parts, with the characteristics of high precision and minimal waste of acrylic materials.

Material Properties of Acrylic (PMMA) for CNC Machining

Understanding the material properties of acrylic is essential for achieving successful CNC machining outcomes. Here are some key properties of acrylic relevant to CNC machining:

Density:

1.18 g/cm³ – This influences the weight of the finished product and affects machining parameters like feed rate and speed.

Tensile Strength:

70 MPa (10,153 psi) – A measure of the maximum stress acrylic can withstand while being stretched or pulled before breaking.

Flexural Strength:

115 MPa (16,687 psi) – Indicates the amount of bending stress acrylic can endure without deformation.

Compressive Strength:

Around 90 MPa (13,053 psi) – The capacity of acrylic to resist squeezing forces.

Modulus of Elasticity:

3,000 MPa (435,113 psi) – This elastic modulus indicates the stiffness of acrylic, impacting its flexibility under load.

Transparency:

Acrylic exhibits excellent optical clarity, making it ideal for applications where transparency is desired. Transparent acrylic with a transmittance of up to 92%, this property allows for clear visibility through acrylic components, making it suitable for windows, displays, and lenses.

Impact Resistance:

Despite its transparency, acrylic is remarkably impact-resistant compared to glass. It is less prone to shattering or breaking upon impact, crucial for applications where durability is a concern.

Machinability:

Acrylic is relatively easy to machine using CNC processes. It can be cut, drilled, milled, and turned with precision to create intricate designs and complex shapes. Its machinability allows for the production of detailed components with tight tolerances.

Chemical Resistance:

Acrylic has good resistance to many chemicals, including acids, alkalis, and solvents. This property makes it suitable for applications where exposure to chemicals is expected, such as laboratory equipment and chemical processing environments.

Weather Resistance:

Acrylic exhibits excellent weather resistance, retaining its clarity and color stability even after prolonged exposure to sunlight and outdoor elements. This property makes it suitable for outdoor signage, architectural features, and marine applications.

Thermal Stability:

Acrylic has a high softening temperature, allowing it to withstand moderate temperatures without deformation. However, it has a relatively low melting point compared to some other engineering plastics, limiting its use in high-temperature applications.

Dimensional Stability:

Acrylic has low shrinkage and excellent dimensional stability, meaning that parts machined from acrylic are less likely to warp or deform during machining or under varying temperature conditions. This property ensures that machined acrylic components maintain their precise dimensions over time.

Surface Finish:

Acrylic can achieve a smooth, polished surface finish, enhancing its aesthetic appeal. CNC machining processes can produce acrylic parts with excellent surface quality, eliminating the need for additional finishing steps in many cases.

Advantages of Acrylic CNC Machining:

Precision:

CNC machines offer high precision and accuracy, ensuring that intricate designs and tight tolerances can be achieved in acrylic parts.

Versatility:

Acrylic CNC machining can produce a wide range of shapes, sizes, and geometries, including complex contours and sharp edges.

Smooth Finish:

CNC machining provides a smooth surface finish on acrylic parts, eliminating the need for additional polishing or finishing processes.

Cost-Effective:

Despite its precision, CNC machining can be cost-effective for both prototyping and production runs of acrylic parts.

Customization:

CNC machining allows for easy customization of acrylic parts to meet specific design requirements and client preferences.

Quick Turnaround:

With automated processes, CNC machining offers fast turnaround times, reducing lead times for acrylic component production.

Applications of Acrylic CNC Machining:

Signage and Displays:

Acrylic is commonly used for signage, point-of-sale displays, and exhibition stands due to its transparency and visual appeal.

Prototyping:

Acrylic CNC machining is ideal for prototyping new products or components, allowing designers to quickly iterate and test designs.

Architectural Models:

Acrylic is often used in architectural models and scale prototypes to visualize building designs and layouts.

Automotive Components:

Acrylic parts find applications in automotive interiors, such as instrument panels, dashboard components, and light lenses.

Medical Devices:

Acrylic is suitable for medical device enclosures, equipment housings, and laboratory components due to its biocompatibility and clarity.

Electronics Enclosures:

CNC-machined acrylic enclosures provide protection for electronic devices while allowing for visibility of internal components.

Art and Decor:

Artists and designers use acrylic CNC machining to create sculptures, artworks, and decorative pieces due to its aesthetic appeal and ease of fabrication.

In conclusion, acrylic CNC machining offers numerous benefits for the fabrication of precision components across various industries. Its versatility, precision, and cost-effectiveness make it a preferred choice for applications requiring transparent and intricately shaped parts. Whether for prototyping, production, or custom projects, acrylic CNC machining provides a reliable solution for bringing designs to life with exceptional clarity and quality.