The terms “jigs” and “fixtures” are called synonymous with each other many times, and sometimes these two terms are used together as a “jig fixture“.

Jig or fixture? These two terms are easily confused. You will often find them paired together, jigs and fixtures are very common tools in the production process. They are used in production to ensure part quality and increase productivity, but functionally speaking, the two are different tools and the two are not interchangeable.

So Today we will study what are Jigs and Fixtures? Difference between jig and fixtures, their types, applications and advantages.

What is Jig?

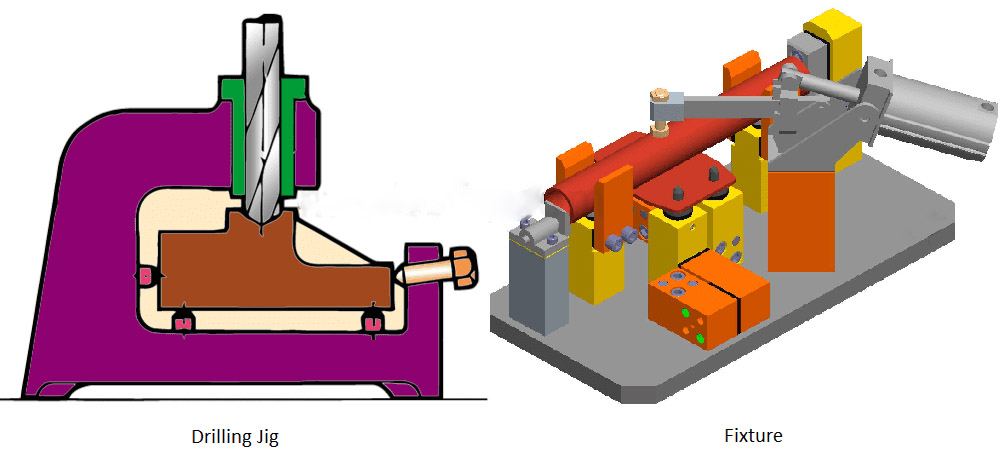

A jig is a work-holding device that holds, support, and locates the workpiece, and guides the cutting tool to be used in most cases to ensure operation in the correct position, and is mainly used for drilling, tapping, and reaming operations .

Jigs are usually equipped with hardened steel bushings to guide cutting tools. Help to improve the repeatability, accuracy and productivity of the manufactured parts by holding the work pieces and guiding the tools.

In addition, it also helps the machine to position the workpiece. The mark for determining the proper position on the workpiece is usually given on the outer packaging of the fixture itself. This design allows users to easily position and hold it in place.

Using jigs can reduce the time required to locate the position, which also makes the work easier. It also aids in locating and controlling the motion of the tool working on the workpiece.

What is Fixture?

The fixture is a tool that accurately holds the workpiece and machine tool in the desired position. Depending on the machining operation and the location of the part to be removed, one or more workpieces can be placed in a fixture. Fixtures are widely used for all types of machining and very large workpieces. The fixing device should be firmly fixed on the machine table to complete the work.

It is used for multi-dimensional machining such as milling, grinding, turning, etc. Compared with the fixture, the fixing device does not guide the cutting tool, and is widely used in manufacturing and assembly operations, to reduce workpiece preparation, unloading and fixing time and improve part quality.

Jig VS Fixture, What is the differences?

The jig tool is a machine that contacts the cutting tool and helps guide the cutting tool. It is mainly used for spacing and positioning drilling. Commonly used fixture tools are called drilling fixtures. This tool helps guide the drill bit in the process of making holes in the desired location.

The fixture is a tool that helps to fix the workpiece in precise positions along the machine tool. It helps to reduce unproductive fixed time, unloading and loading of workpieces. It does not directly contact the cutting tool and does not guide the cutting tool. It only provides references to equipment or surfaces.

|

Jigs |

Fixtures |

|

Help in holding the piece in place as well as locating the points for the tool to work. It also aids in guiding the tool for their precise function. |

Specifically be used to locate and support the piece in place for the tool to function. Do not guide the tools for their operation. |

|

Comes in contact with the machine to guide the tool to work on the piece. |

Do not come in contact with the tool for it to function. It accurately sets the angle and position for the tool to function. |

|

Complex Design |

Simple Design |

|

Lightweight , small in size and easy to handle. |

Bulky, relatively large and fixed with workbench.. |

|

It doesn’t need a gauge block to work. |

Require gauges to precisely locate the position for the machine to work. |

|

Often come in a portable and compact variant. |

Fixed on the tables for providing the proper support to the workpiece. |

|

It is expensive as compared to the fixtures. |

The tools cost less than the jigs. |

|

It is used in unidimensional working machines such as cutting, tapping, etc. |

It is useful for tools working in multidimensional ways such as grinding, drilling, etc. |

|

Jigs are used extensively for cutting and drilling tools. It is also used widely in wood drilling industries. |

Fixtures are used for milling, slotting and shaping tools. It is useful for tools working in multidimensional ways such as grinding, drilling, etc. |

Advantages Of Jigs And Fixtures

Increased Productivity

Increased Productivity

Jigs and fixtures eliminate the need to repeatedly align the workpiece. Therefore, the idle time of the machine is reduced and the productivity is improved.

Reduce Manufacturing Costs

The use of clamps and fixtures reduces production time. Therefore, the product cost is reduced.

Quality Improvement

Jigs and fixtures reduce the need for manual setting and meet a certain degree of automation requirements. Therefore, the quality of the manufactured parts is improved.

Improve Precision

Using jigs and fixtures together helps achieve manufacturing precision required for products to function properly.

Types of Jigs and Fixtures

The complexity, model, and quantity of jigs and fixture depends on the work type to be a machine as well as the production scale required. Here is a list of different kinds of jigs and fixtures that common used.

Jigs Types

- Template jig

- Plate jig

- Diameter jig

- Channel jig

- Ring jig

- Box jig

- Angle-Plate Jigs

- Multi-Station Jig

Fixtures Types

- Assembly fixture

- Duplex fixture

- Tapping fixture

- Indexing fixture

- Grinding fixture

- Milling fixture

- Turning fixture

- Test fixture

Application of Jigs&Fixtures

Typically, the jigs and fixtures are used for machining operations. Other operations, however, such as assembly, inspection, testing, and layout, are also areas where work holding devices are well suited.

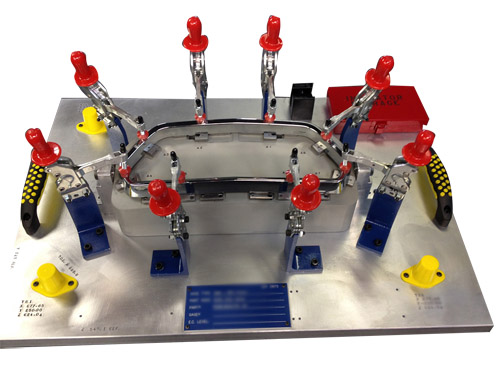

There are many fields where we can use jigs and fixtures, such as auto parts production lines, medical device parts production lines, aviation component assembly lines, automated equipment assembly, industrial manufacturing etc..

Conclusion

Custom jigs and fixtures can help operators ensure accurate and repeatable work. Jigs and fixtures play a very important role in product manufacturing. They help increase productivity and quality and reduce costs

Jig and fixture fabrication requires close tolerance detailed machining. We have CNC and precision machining capabilities, however we also have the profound knowledge required for manual jig and fixture machining. As ISO 9001:2008 compliant factory, we have produced many custom jigs and fixtures for a wide range of industries including aerospace, military, automotive, medical etc..

Send Your Design For Free Quote Now