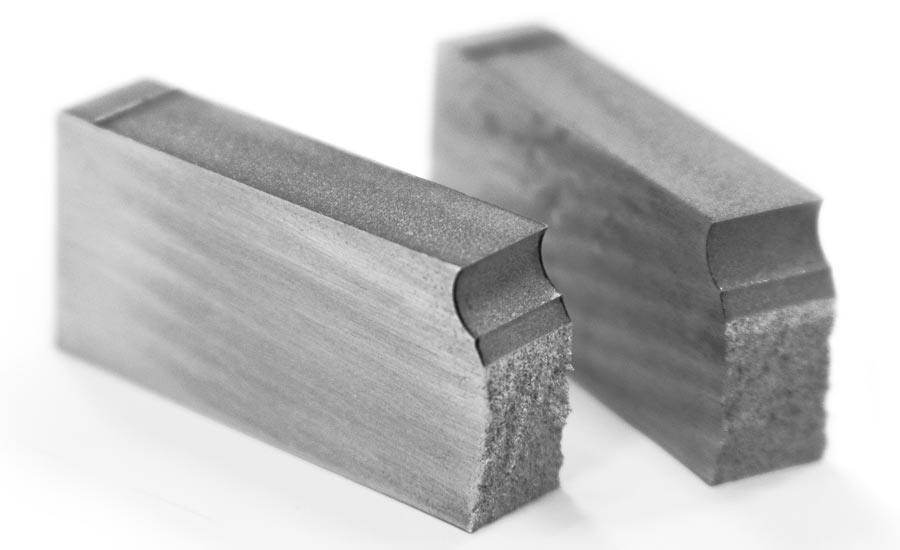

Fracture failure is a critical issue in the realm of mechanical engineering, often leading to catastrophic consequences. It occurs when a material breaks or separates into two or more pieces due to excessive stress. Understanding the causes and mechanisms behind fracture failures is crucial for preventing such occurrences in mechanical parts. Let’s explain the key aspects of fracture failure.

-

Types of Fracture:

Ductile Fracture: Occurs in materials that deform significantly before rupture. It often exhibits necking and tearing features.

Brittle Fracture: Happens with little or no plastic deformation. The material fails suddenly, often without warning.

-

Causes of Fracture Failure:

Excessive Load: Applying a load beyond the material’s strength can lead to fracture. It’s crucial to consider both static and dynamic loads.

Material Defects: Inclusions, voids, or other defects in the material’s structure can act as stress concentration points, initiating fractures.

Improper Design: Flaws in the design, such as sharp corners or sudden changes in geometry, can result in stress concentrations and fracture.

Corrosion: Weakening of materials due to corrosion can significantly contribute to fracture failures.

Temperature Effects: Extreme temperatures can alter material properties, making it susceptible to fracture.

-

Fatigue Failure:

Repeated Loading: Cyclical loading, even below the material’s yield strength, can lead to fatigue failure over time.

Crack Propagation: Microscopic cracks initiate and propagate with each loading cycle until a critical size is reached, resulting in catastrophic failure.

-

Impact Loading:

Sudden Impact: High-velocity impacts, as seen in accidents or collisions, can induce fracture failures in materials that may otherwise withstand static loads.

-

Prevention Strategies:

Material Selection: Choose materials with suitable properties for the intended application and environment.

Design Considerations: Incorporate designs that minimize stress concentrations and avoid abrupt changes in geometry.

Regular Inspection: Implement inspection and maintenance schedules to identify and address potential issues before they lead to failure.

Material Testing: Conduct thorough material testing to detect defects and ensure the material’s integrity.

Load Analysis: Perform precise load analysis to ensure that mechanical parts operate within their designed limits.

-

Failure Analysis:

Root Cause Analysis: Investigate the root causes of fractures through detailed analysis of failed components.

Microscopic Examination: Use techniques like microscopy to examine the fracture surfaces and identify the fracture mode.

Understanding fracture failure is integral to enhancing the reliability and safety of mechanical components. By addressing the root causes, employing preventive measures, and conducting thorough analyses, engineers can mitigate the risks associated with fracture failures in mechanical systems.