In the realm of machining and manufacturing, blind holes are a common feature that serves specific purposes in the design and functionality of components. We introduce what blind holes are, their applications, and the machining techniques involved.

What Are Blind Holes?

A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. It has a bottom that prevents the hole from penetrating the entire thickness of the workpiece. These holes are often strategically incorporated into designs to achieve specific structural or functional objectives.

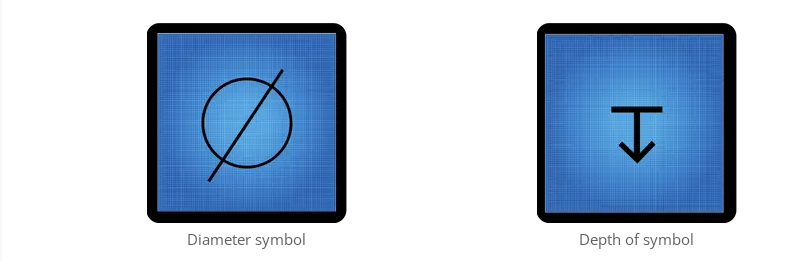

Blind Hole Symbol

There is no GD&T symbol for a blind hole. A blind hole will be specified with a diameter and a depth specification or remaining amount of material.

Applications Of Blind Holes:

Fastening and Joining: Blind holes are frequently used for fastening purposes. For example, screws, bolts, or dowel pins may be inserted into blind holes to securely join components without protruding through the other side.

Fluid Containment: In hydraulic and pneumatic systems, blind holes can be designed to contain fluids without the risk of leakage. This is crucial in applications where maintaining a sealed environment is essential.

Enhanced Structural Integrity: By incorporating blind holes, engineers can enhance the structural integrity of a component. This is achieved by strategically placing blind holes to redistribute stress, reduce weight, or improve balance.

Machining Techniques For Blind Holes:

Drilling: The most common method for creating blind holes is drilling. Specialized drill bits, such as gun drills or deep-hole drills, are used to create holes of varying depths.

Boring: For larger or more precise blind holes, boring operations may be employed. Boring involves enlarging an existing hole to achieve greater accuracy.

Trepanning: This process involves removing material to create a hole and leaving a core. Trepanning is advantageous for creating large-diameter blind holes.

Gun Drilling: Particularly useful for deep blind holes, gun drilling employs a long, specialized drill to create holes with high precision.

Measurement And Inspection Techniques For Blind Holes

Depth Measurement:

Depth Gauges: Use depth gauges to measure the depth of blind holes accurately. Vernier depth gauges or digital depth gauges are commonly employed.

Calipers: For larger blind holes, calipers with depth measurement capabilities can be utilized.

Depth Micrometers: Highly precise measurements are achieved using depth micrometers.

Optical Measurement:

Borescopes: Employ borescopes or endoscopes to visually inspect the interior of blind holes. This is particularly useful for detecting surface defects or irregularities.

Optical Comparators: Compare the features of a machined part with a magnified optical image for detailed inspection.

Ultrasonic Testing:

Ultrasonic Thickness Gauges: These gauges utilize ultrasonic waves to measure the thickness of the material remaining at the bottom of the blind hole.

Coordinate Measuring Machines (CMM):

Touch Probes: CMMs equipped with touch probes can accurately measure the dimensions of blind holes.

Laser Scanning: Non-contact laser scanning on CMMs can capture detailed surface information.

X-ray and CT Scanning:

X-ray Inspection: X-ray imaging can be employed to inspect internal structures of blind holes.

CT Scanning: Computerized Tomography (CT) scanning provides three-dimensional insights into the internal features of a part.

Air Gauging

Air Plug Gauges: These gauges use compressed air to measure the depth and diameter of a blind hole.

Go/No-Go Gauges:

Thread Plug Gauges: For blind holes with threads, thread plug gauges can ensure proper thread dimensions.

Ring Gauges: Confirm the diameter and depth with ring gauges.

Optical Profilers:

White Light Interferometry: Optical profilers use white light interferometry for high-resolution 3D surface profiling of blind holes.

Potential progress in blind hole engineering

Blind holes are a key element in engineering and mechanical processing, and with the advancement of technology, the importance of blind holes will only increase.

One important trend that may affect the future of blind hole machining is the advancement of materials and tools. With the advancement of materials and fixtures, they can improve the efficiency, accuracy, and flexibility of blind hole processing. The development of instrument coatings, material science, and manufacturing methods will have a significant impact on the future of hole processing.

In short, the importance of blind holes in engineering and mechanical processing cannot be overemphasized. Blind holes play a crucial role in improving the robustness of parts, reducing material waste, and providing designers and mechanics with multiple options for part creation. With the advancement of technology, blind hole machining must be constantly explored and innovated to ensure its high efficiency, lightweight, and reasonable structure.