CNC stands for Computer Numerical Control Machine, which is used to remove material by using precision and high-speed cutting tools, and finally form the final design. Programming the CNC machine and determining its movement is the key, and the instructions can be completed using coded computer-aided manufacturing software and CAD files.

The original CNC equipment can be programmed in two-axis (meshing) and three-axis (milling), but with the development of control, servo and tool technology, we can now complete 4-axis and 5-axis simultaneous machining. Using a 5-axis machine, you have 2 more motion axes compared to a 3-axis machine. This advanced machining technology enables manufacturers to produce parts with more complex or more complex designs at a faster speed and higher quality without the need for additional processing.

What Is 5 Axis CNC Machining?

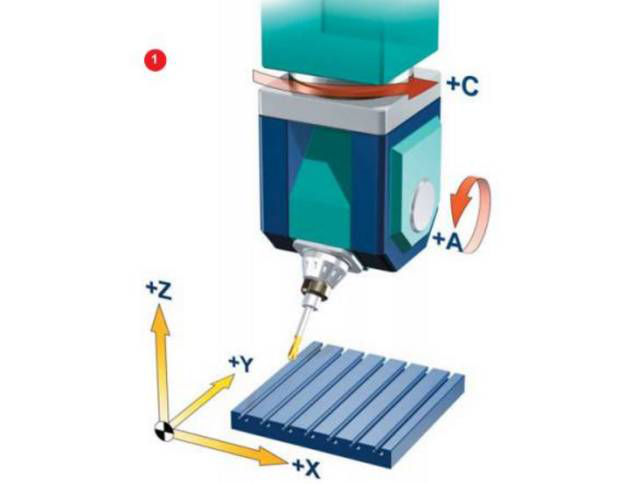

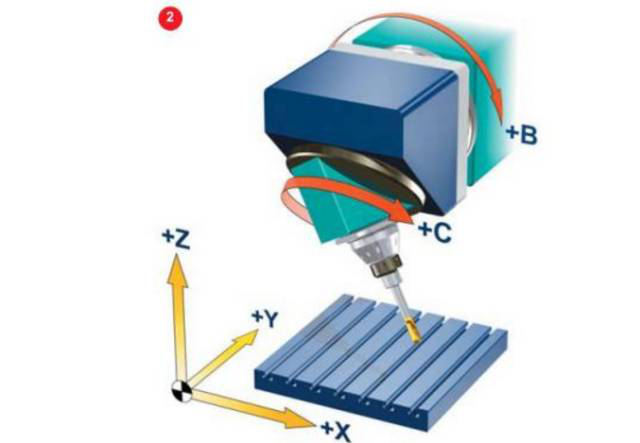

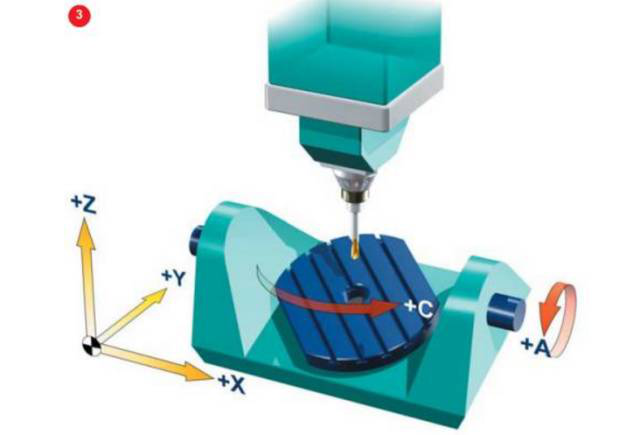

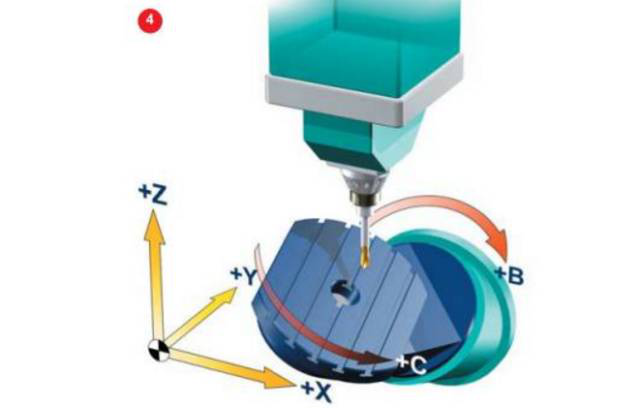

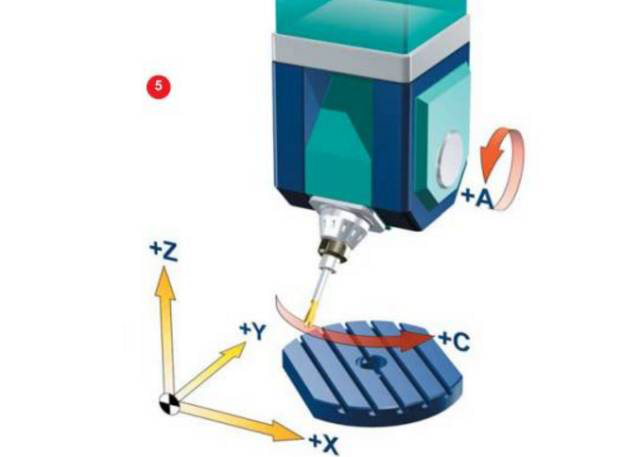

Five-axis refers to the three moving axes of x, y, and z plus any two rotating axes. Compared with the common three-axis (x, y, z three degrees of freedom) machining, five-axis machining refers to the processing of more complex geometrical parts, the machining tool needs to be positioned and connected in five degrees of freedom. They use several different axis configurations to perform machining operations. (CNC Machining: 3 Axis VS 4 Axis VS 5 Axis)

The current Type of five-axis CNC machines

In the mechanical design of 5-axis machining centers, machine manufacturers have always been unremittingly committed to developing new motion modes to meet various requirements. In summary, there are various types of five-axis machine currently on the market. Although their mechanical structures are in various forms, there are mainly the following 5 types:

- Two rotating coordinates directly control the direction of the tool axis (double swing head form)

- The two coordinate axes are at the top of the tool, but the rotation axis is not perpendicular to the linear axis (pitch type swing head type)

- Two rotating coordinates directly control the rotation of the space (double turntable form)

- The two coordinate axes are on the worktable, but the rotation axis is not perpendicular to the linear axis (pitching worktable)

- Two rotating coordinates, one acting on the tool and one acting on the workpiece (one swing and one rotation)

The 5-axis machining is believed to increase efficiency and reduce the time required. The 5-axis provides flexibility and avoids possible collisions with the tool holder. The title of the tool to be cut is located in the appropriate position, which also provides an appropriate posture for cutting. The configuration of 5-axis machining defines the axis to be used. The shaft requirements depend on the machine and tool to be cut, and it completely depends on whether the part is single or multiple.

Advantages Of 5 Axis CNC Machining

Fewer Setup

The first and most important point is the ability to machine complex shapes in a single setting. For contour parts or machining on multiple faces, 3-axis machine require multiple settings, which may lead to incorrect alignment, higher The cost and other errors. The five-axis machine can machine almost all visible surfaces except the bottom or clamping area. This capability greatly reduces the need for multiple settings or special fixtures. In some cases, it reduces the number of settings to one. This improves efficiency, saves time, reduces costs and prevents operator errors.

Complex Shapes

5-axis machining also provides the ability to machine extremely complex parts from a solid, and this type of machining can also save a lot of drilling time. Drilling a series of holes with different compound angles is very time consuming. With a five-axis machine, the drill can be automatically oriented along the correct axis for each hole, so that the drilling can be completed faster.

5-axis CNC machine can reach even the most complex angles. If your parts require complex 4D and 5D parts, then you need a machine shop equipped with 5-axis machines and the best operators. Combined with the highest finishing and tolerances, we are able to achieve complexity that cannot be achieved with 2-axis or 3-axis machine. It only needs to be set once, which can be transformed into higher productivity and higher workpiece quality.

This process allows you to machine complex parts that would otherwise require casting. If you have low-volume production or prototype manufacturing, you can machine parts in a few weeks instead of waiting months to complete the casting.

Amazing Accuracy, Efficiency and Cost Effective

5-axis machining is the more efficient and accurate one among all similar products. Since the number of fixtures in multiple operations is small, the use of it can directly translate into better machined parts quality and durability. This means good parts, less waste, low mold costs and short working hours.

Every time the setting is changed, a small error occurs. Using fewer settings, or even only 1 setting, can eliminate this source of error, feature-to-feature accuracy is improved.

Shorter Cutting Tools

5-axis machining allows you to use shorter cutting tools because you can lower the tool head and orient the tool appropriately. This helps achieve higher cutting speeds without putting too much pressure on the cutter. When the machine holds the tool well, the load on the tool is reduced, and the shorter cutting tool can reduce the vibration of the tool, thereby reducing unfortunate fracture and vibration.

Better Surface Finish

By using the fourth and fifth axis of rotation, we can move the part closer to the cutting tool. If the part can be closer to the cutting tool, the cutting tool can be shorter. Shorter cutting tools are less susceptible to vibration at higher cutting speeds, which directly affects surface finish. Shorter tools and less deflection mean less chattering and better surface finish.

Improve Tool Life

It can maintain a constant chip load and optimal cutting position, thereby extending the cycle time and life of the tool. Shorter tools have higher rigidity and will not cause excessive tool deflection, thereby prolonging the life of the tool.

Application Of 5 Axis CNC Machining

5-axis machining can be widely used in all walks of life, especially in applications that require parts with complex geometries and strict tolerances.

This manufacturing process is most popular in the aerospace industry, but these useful attributes have prompted more industries to adopt it. Industries that benefit from this process include oil and gas, medical, alternative energy, and automotive industries.

Conclusion

The advantages of five-axis machining are very obvious, including saving time and money, which is self-evident. Five-axis linkage CNC is the most difficult and most widely used technology in CNC technology. It integrates computer control, high-performance servo drive and precision machining technology, and is used in the efficient and precise automated machining of complex curved surfaces. Although 5-axis CNC machines are expensive, they are now the main products in forward-looking machine factories.

I like that you mentioned that working with stronger materials is a lot more cost-effective by using a CNC machine. Perhaps it would indeed benefit me a lot if I start looking for CNC machine training online soon. I’ve always been interested in metallurgy and I think I can spend some time in elevating my technical knowledge about this hobby of mine.