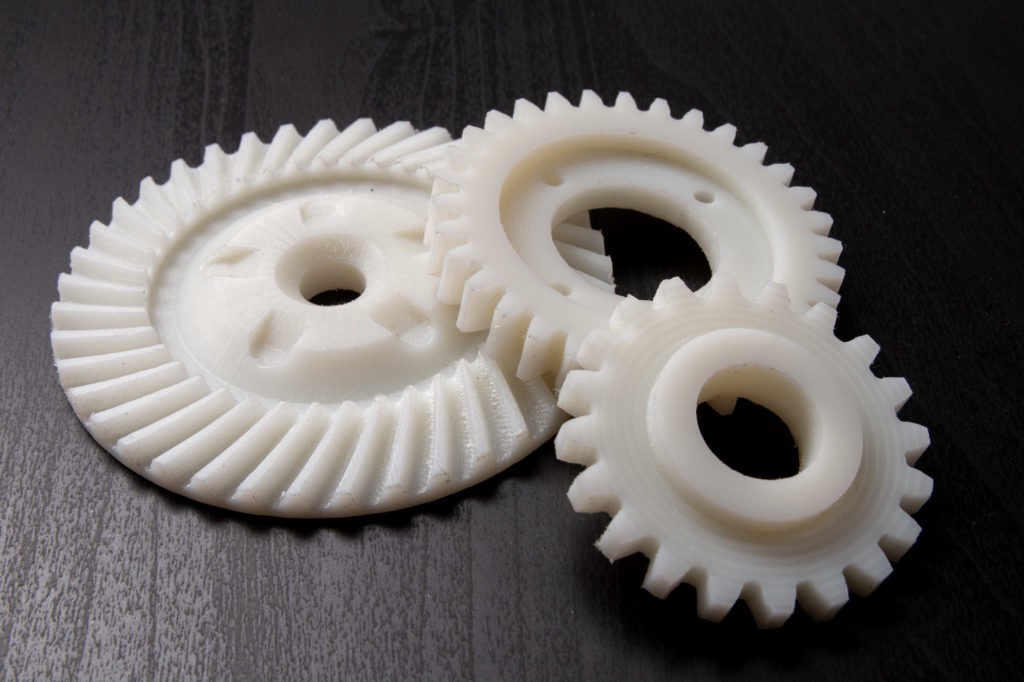

Nylon refers to a group of plastics called polyamides. It is easy to process and can be used as various mechanical end parts. It is one of the most common engineering plastics in the world, with excellent bearing and wear resistance.

It can be used as a homopolymer, copolymer or reinforcing material. It can also be pre-treated to reduce its hygroscopicity during its service life. Provide oil-filled and glass-filled grades.

Properties & Grades of Machined Nylon (PA)

As a thermoplastic, nylon has industrial-grade resistance to pH changes (due to different thermal conditions) and solvent resistance. This may be an advantage in the petrochemical industry where fluoropolymer parts are in contact or exposed to gas, oil, or cleaning agent explosions.

It should also be noted that nylon (PA) is known for its high crystallinity, which results in a stronger and strain-resistant composition. In addition, the use of nylon reduces the need for large amounts of lubrication, reduces sound and eliminates wear, corrosion, and theft issues.

Nylon 6 and Nylon 6/6 There are two common grades of nylon, and their characteristics and applications are worth mentioning. They can be used interchangeably in various applications, but there are some attribute differences.

Nylon 6 is usually produced in two forms: a high-strength type for textile applications and a high-strength type for industrial use. It usually forms filament yarns and staple fibers. In most cases, this nylon can be found in tire cords, parachutes, ropes or industrial cords. Much like nylon 6, nylon 6/6 has many industrial applications, from thin-walled parts to large thick-walled bearings. It is also an outstanding candidate for metal substitutes.

Advantages Of Nylon:

1. High mechanical strength, good toughness, high tensile and compressive strength.

The specific tensile strength is higher than that of metals, and the specific compressive strength is comparable to that of metals, but the rigidity is not as good as that of metals. The tensile strength is close to the yield strength, which is more than twice that of ABS. It has a strong ability to absorb shock and stress vibration. The impact strength is much higher than that of general plastics and better than acetal resins.

2. Excellent fatigue resistance.

Parts made of nylon can maintain the original mechanical strength performance after being alternately bent. PA can usually be used in occasions where periodic fatigue is very obvious, including escalator handrails, plastic rims of new bicycles, etc.

3. High softening point and heat resistance

(Such as nylon 46, high crystallinity nylon has a high heat distortion temperature and can be used for a long time at 150 degrees. After PA66 is reinforced with glass fiber, its heat distortion temperature can reach 250 degrees or more).

4. The surface is smooth, the friction coefficient is small, and it is wear-resistant.

When used as a movable mechanical part, it is self-lubricating, with low noise, and can be used without lubricant when the friction is not too high; if you really need a lubricant to reduce friction or help heat dissipation, you can choose water, oil, grease, etc. Therefore, as a transmission component, its service life is long.

5. Corrosion resistance

Very resistant to alkalis and most salt solutions, also resistant to weak acids, motor oils, gasoline, resistant to aromatic compounds and general solvents, inert to aromatic compounds, but not resistant to strong acids and oxidants. It is resistant to the erosion of gasoline, grease, alcohol, and weak bumps, and has good anti-aging ability. It can be used as packaging material for lubricating oil and fuel.

6. Self-extinguishing, odorless, non-toxic, weather resistant, immune to biological erosion, good antibacterial and mildew resistance.

7. Excellent electrical properties.

Because nylon has a high volume resistivity, it will not be easily broken down by high voltage. In a dry environment, it can be used as a power frequency insulating material; in high humidity conditions, it can still maintain good electrical insulation.

8. Light weight, easy to dye and shape.

Its melt viscosity is low and it can flow quickly. High freezing point, easy injection molding, fast molding speed, short molding cycle and high production efficiency.

Disadvantages Of Nylon (PA)

- Poor water absorption and poor dimensional stability. Uneven wall thickness can cause distortion and deformation of mechanical parts. High requirements for machining equipment. It is not easy to resist strong acids and strong oxidants. Cannot be used as an acid-resistant material.

- Poor low temperature resistance.

- Poor antistatic property.

- Poor heat resistance.

Application Of Nylon

Nylon material is an engineering thermoplastic, easy to process, and can be used as a variety of mechanical end parts. Today, it has been widely used in a variety of applications, including clothing, rubber-like car tire reinforcement, as a rope or thread, and many injection molded parts for vehicles and machinery. Such as bearings, bushings, wheels, rollers, etc.