Stainless steel is widely used because of its corrosion resistance. There are many grades of stainless steel, and their formability, strength and workability are different. Grade 304 stainless steel, also known as A2 stainless steel, contains 18% to 20% chromium and 8% to 10% nickel.

Grade 316 stainless steel or A4 stainless steel contains approximately 16% chromium, 10% nickel, and 2% to 3% molybdenum. This means that one of the biggest differences between 304 and 316 stainless steel is the presence of molybdenum in 316, and no molybdenum is added to 304.

This element is added to help it resist corrosion by chlorides. Grade 316 steel also contains trace amounts of silicon, carbon and manganese. The presence of molybdenum makes 316 stainless steel known as marine grade stainless steel. Type 316 stainless steel is more resistant to chemical corrosion. For example, it will resist fatty acids and sulfuric acid at high temperatures. Grade 316 stainless steel can withstand temperatures up to 1600 degrees Fahrenheit. Compared with 316, grade 304 stainless steel is less heat-resistant.

What Grade Of Stainless Steel Is Most Suitable For Machining?

Austenitic stainless steels are generally considered difficult to machine. 400 series stainless steels are easier to machine than 300 series stainless steels. This includes 304 and 316 grades. The machinability of 304 and 316 grade stainless steel is indeed different. Type 303 stainless steel may be the easiest 300 series to be processed. It is easier to process than 304. This makes grade 303 steel the first choice for accessories, gears and fasteners with strict tolerances. Its relative weakness means that it is not used as often as 304 grade stainless steel.

304 is easier to process than 316 stainless steel. Grade 304 steel is not only easier to process, but also easier to clean, which is one of the reasons why it has so many different finishes, and this is why it is used for surfaces that are visible to the public. Type 316 stainless steel is not only difficult to machine, but also requires special tools for cutting. It performs well in pitting corrosion resistance, but it is not so easy to form, which explains why it is reserved for applications that other types of stainless steel cannot handle.

What Grade Of Stainless Steel Is Easier To Process

Stainless steel grades have a series of allowable other metal contents to maximize machinability. In addition to the difference in machinability between various types of stainless steel, this makes 316 grade steel easier to process than 316B. The machinability grade of 316 steel is 60, while the machinability grade of 316B is 50, and the machinability grade of 304 and 304L grades is the same, both are 70. In contrast, Alloy 303 is the easiest stainless steel to process. It has a machinability level of 150 and a baseline machinability level of 100.

How To Improve The Workability Of Stainless Steel

Adding sulfur or selenium will also improve the workability of stainless steel, which is also easier to corrode and interfere with welding. The sulfur content of stainless steel alloy 303 is much lower than that of stainless steel 304, and the allowable carbon content of weldable stainless steel is lower. For example, 304 stainless steel contains up to 0.08% carbon, while 304L or weldable 304 stainless steel contains up to 0.03% carbon, which does not really affect its workability.

How To Process 304 VS 316 Stainless Steel

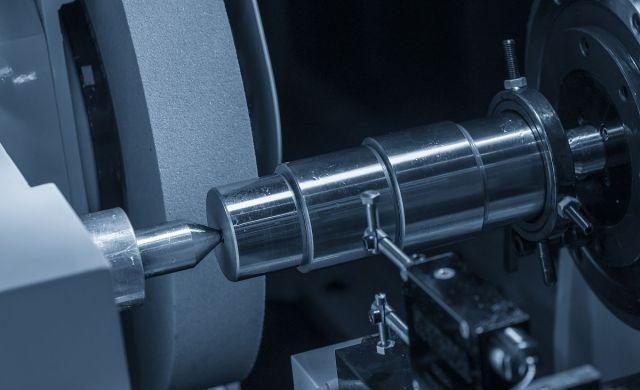

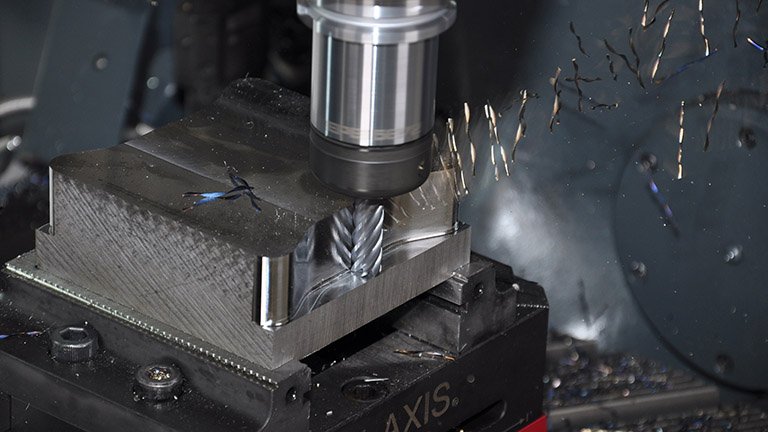

To process 304 steel or 316 steel, you do not want the machine to be subjected to excessive vibration, and you need to use large machines. Small lathes and milling machines cannot cut these grades of stainless steel. For any type of stainless steel, carbide tools or high-speed steel (HSS) tools can be used. When working at lower cutting speeds, high-speed steel tools are a better choice.

All 300 series stainless steels have a certain degree of work hardening, and 316 grades are easier to harden, and more effort is needed to prevent this from happening. One solution is to use sharp tools and change tools when they start to wear out, and work at a slower speed and higher feed compared to Machining 304. To process 304 stainless steel, it should be processed at a slower speed. When processing complex grade 304 steel, use deep cutting at a high feed rate to minimize work hardening.

Conclusion

In the ideal process for machining 304 and 316 stainless steels, there are several ways to make all 300 series stainless steels easier to machine. Heat treatment can be performed to make the metal easier to process, for example, normalizing heats the steel to a temperature higher than the annealing temperature. Keeping it long enough to produce smaller austenite grains improves the machinability of the steel. These types of steel have low thermal conductivity. Be careful not to overheat the surface, which can also cause distortion that is difficult to repair. Use oil lubrication to reduce tool wear and cool objects. You can use mineral oil or water-soluble emulsified oil, and use cemented carbide tools to work at high speed.