Chrome plating is a versatile surface finishing technique used in various industries to enhance the appearance, durability, and performance of metal parts. Chrome plating can enhance the mechanical properties of designed components. It can also have aesthetic or decorative purposes. Two common types of chrome plating are hard chrome plating and decorative chrome plating. While both processes involve depositing a layer of chromium onto a substrate, they serve different purposes and exhibit distinct characteristics.

Here will give a detailed comparison between the two chrome plating, hope this post can help you choose the best option for your project.

What Is Hard Chrome Plating?

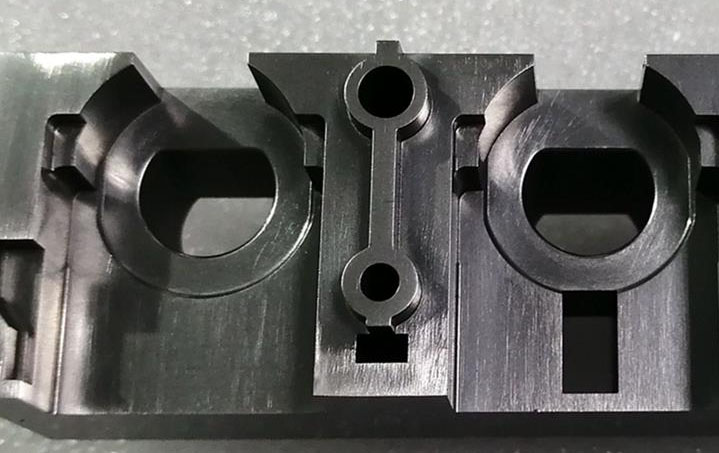

Industrial hard chromium plating is a type of surface treatment for electroplating. It usually also refers to functional chrome plating and engineering chrome plating. This type of chrome plating process involves depositing chromium onto the metal surface.

The chromium layer protects components and improves durability by increasing wear and corrosion resistance, as well as reducing friction. Engineers and manufacturers combine base materials with surface smoothness to achieve the required quality, reliability, and efficiency.

What Is Decorative Chrome Plating?

This type of chromium plating involves depositing a thin layer of chromium on a nickel plated substrate. The function of the chromium layer is to protect the nickel coating from oxidation and loss of luster. The added thin chrome layer brings a slight blue tone while also preventing scratches.

The main purpose of this chrome plating method is to provide aesthetically pleasing functionality for the components. Although it also has corrosion resistance and wear resistance, its thickness is not sufficient to provide durability similar to that of a hard chromium coating.

Differences Between Hard Chrome Plating And Decorative Chrome Plating

Purpose:

Hard Chrome Plating:

Hard chrome plating, also known as industrial chrome plating or functional chrome plating, is primarily used to improve the wear resistance, corrosion resistance, and hardness of metal components. It provides a durable, low-friction surface that can withstand harsh operating conditions, making it suitable for applications such as hydraulic cylinders, piston rods, machine components, and industrial tools.

Decorative Chrome Plating:

Decorative chrome plating, also referred to as bright chrome plating or decorative nickel-chrome plating, is primarily used for aesthetic purposes to enhance the appearance of metal parts. It creates a shiny, mirror-like finish that adds visual appeal and decorative value to consumer products, automotive trim, motorcycle parts, household fixtures, and jewelry.

Thickness and Finish:

Hard Chrome Plating:

Hard chrome plating typically results in a thicker coating compared to decorative chrome plating, ranging from 0.001 to 0.1 inches (25 to 2500 microns). The surface finish of hard chrome plating is functional rather than decorative, with a matte or slightly textured appearance. The primary goal of hard chrome plating is to provide a durable, abrasion-resistant coating that improves the performance and longevity of metal parts.

Decorative Chrome Plating:

Decorative chrome plating produces a thin layer of chromium, typically ranging from 0.0001 to 0.001 inches (2.5 to 25 microns). The finish is highly reflective and lustrous, creating a brilliant, mirror-like surface that enhances the visual appeal of the plated object. Decorative chrome plating is often used to give metal parts a glossy, upscale appearance and is commonly found in automotive trim, household appliances, and consumer electronics.

Surface Preparation and Application:

Hard Chrome Plating:

Hard chrome plating requires meticulous surface preparation, including polishing, cleaning, and etching, to ensure proper adhesion and uniform deposition of the chromium layer. The plating process typically involves electroplating, where chromium is deposited onto the substrate through an electrolytic bath using a direct current (DC) power source. Hard chrome plating is performed under controlled conditions to achieve the desired thickness and properties.

Decorative Chrome Plating:

Decorative chrome plating also involves thorough surface preparation, but the emphasis is on achieving a flawless, blemish-free finish rather than functional properties. The plating process may include multiple steps, such as copper plating, nickel plating, and chrome plating, to achieve the desired brightness and durability. Decorative chrome plating is often performed in decorative plating shops using specialized equipment and techniques.

Applications:

Hard Chrome Plating:

Hard chrome plating is commonly used in industrial applications where durability, wear resistance, and corrosion resistance are critical, such as hydraulic and pneumatic components, machine parts, molds, and cutting tools.

Decorative Chrome Plating:

Decorative chrome plating is prevalent in consumer products, automotive trim, motorcycle parts, household fixtures, and architectural elements where aesthetics and visual appeal are paramount.

Conclusion

In summary, hard chrome plating and decorative chrome plating serve different purposes and exhibit distinct characteristics. Hard chrome plating is valued for its functional properties, providing durability and performance in demanding industrial applications, while decorative chrome plating enhances the aesthetic appeal of consumer products and automotive accessories with its brilliant, mirror-like finish. Understanding the differences between these two types of chrome plating is essential for selecting the right process for specific application requirements.