In today’s world, people’s demand for personalization and uniqueness is increasing, and they are no longer satisfied with traditional mass-produced products. The emergence of CNC machining technology has enabled us to meet this personalized demand and transform creativity into practical products.

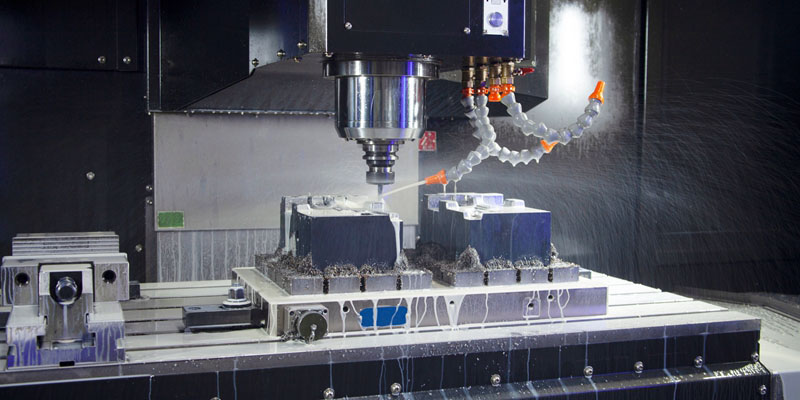

CNC machining is an advanced manufacturing technology that controls machine tools for machining through programming instructions. It has the characteristics of high precision, high efficiency, and high flexibility, making the production process more refined and personalized. Through CNC machining, we can transform unique designs into practical products to meet the personalized needs of consumers.

Suggestions For CNC Machining Customization

1. Selection Of Design Software:

Before starting the design, it is very important to choose a powerful and easy-to-use 3D design software. For example, SolidWorks, UG, Pro/E and other software can help designers quickly create complex 3D models, providing an accurate data foundation for CNC machining. These software also have powerful simulation functions, which can predict the performance and reliability of parts before processing.

2. Process Analysis:

In the design phase, it is necessary to analyze the structure, materials, dimensions, etc. of the parts to determine the optimal processing method and process parameters. This includes selecting the appropriate tool, cutting speed, feed rate, etc. At the same time, it is also necessary to consider possible problems that may occur during the machining process, such as tool wear, excessive cutting force, etc., to ensure the smooth progress of the machining process.

3. Programming And Simulation:

Based on the designed 3D model, write a CNC program and conduct simulation. This step can check the correctness and processing effect of the program, ensuring the dimensional accuracy and surface quality of the parts. In the programming process, it is necessary to pay attention to selecting appropriate tools, cutting parameters, and machining paths to improve machining efficiency and ensure machining quality.

4. Selection Of CNC Machine Tools:

Select a suitable CNC machine tool based on the size, shape, and processing requirements of the parts. There are many types of CNC machine tools, such as vertical machining centers, horizontal machining centers, turning centers, etc. Selection needs to be made based on actual needs to meet the machining accuracy and production efficiency requirements of the parts.

5. Processing Monitoring:

During CNC machining, real-time monitoring of the working status of the machine tool, tool wear, cutting force, etc. is required. This can be achieved through data collection and analysis to ensure the smooth progress of the processing process. In addition, optimizing processing parameters can also improve production efficiency and reduce production costs.

6. Post Processing And Inspection:

After the completion of CNC machining, it is necessary to perform post processing work such as deburring and cleaning on the parts to ensure the surface quality and dimensional accuracy of the parts. At the same time, strict testing of the parts is also required to ensure that they meet design requirements and customer expectations. This can be achieved through precision measurement equipment such as coordinate measuring instruments and optical microscopes.

7. Customer Communication And Feedback:

It is very important to maintain good communication with customers during the personalized customization process. We need to understand the needs and expectations of customers, adjust design plans and processing techniques in a timely manner to meet their personalized needs. At the same time, it is also necessary to collect customer feedback, continuously optimize products and services, and improve customer satisfaction.

Advantages Of CNC Machining Customization

Personalized customization can meet consumers’ unique and personalized needs for products, and has the following advantages:

- Meeting special needs: Personalized customization can manufacture products that meet the special needs of consumers and meet their personalized needs.

- Improving product quality: Personalized customization typically uses high-quality materials and advanced manufacturing technology to improve product quality and reliability.

- Enhance product competitiveness: Personalized and customized products have uniqueness and innovation, which can stand out in the market and improve product competitiveness. Meanwhile, by optimizing design and production processes, waste and environmental impact can be reduced.

Future Development Trends

With the continuous development of technology, CNC machining technology will become more intelligent, automated, and green. In the future, we look forward to CNC machining technology playing a greater role in the field of personalized customization, bringing consumers a higher quality and personalized product experience.

CNC machining technology has broad application prospects in the field of personalized customization. Through reasonable design and processing techniques, the advantages of CNC machining can be fully utilized to achieve the manufacturing of various complex shapes and structures of parts, meeting the personalized needs of consumers for products. With the continuous development and innovation of technology, CNC machining technology will play an increasingly important role in the field of personalized customization.