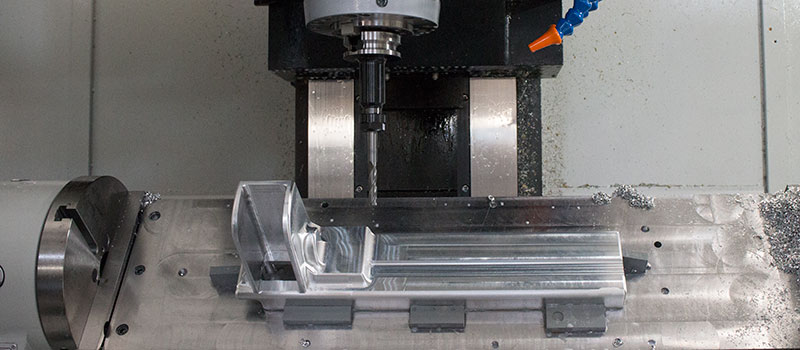

Mechanical parts processing is the assembly and adjustment of processed parts according to drawings or customer requirements, to make them meet the performance requirements of the product. Mechanical component processing includes processes such as turning, milling, planing, grinding, boring, and assembly, which play a very important role in mechanical manufacturing. Therefore, it is a very important technology.

1. Processability

Mechanical parts processing has extremely high machinability. By using different tools and processes, various materials can be cut, drilled, milled, turned, and other operations can be carried out to manufacture the required various parts.

2. Precision

Mechanical parts processing has high precision. Modern mechanical processing equipment can accurately control the relative positions of tools and materials, achieving high-precision operations such as hole processing and surface treatment. This helps to ensure the dimensional and shape accuracy of the parts, thereby improving the performance and quality of the product.

3. Quality Stability:

Mechanical parts processing has good quality stability. By adopting advanced processing equipment and processes, as well as a strict quality control system, we can ensure that the quality of each component meets the requirements. In addition, standardization and serialization of production can reduce production costs and improve production efficiency.

4. Material Diversity:

Mechanical parts processing can handle raw materials of various materials. Whether it is metal, plastic, ceramics, or composite materials, they can be converted into the required parts through mechanical processing. This enables the machining of mechanical parts to have a wide range of applications and flexibility, which can meet the needs of different fields.

5. Highly Customized

Through different processing equipment and processes, customized production can be tailored to the needs of different customers. This flexibility gives mechanical component processing great advantages in meeting personalized needs.

6. Efficiency

Modern mechanical processing equipment can quickly cut, shape, and assemble raw materials, greatly improving production efficiency. This makes mechanical component processing one of the important production methods in modern manufacturing.

7. Can Achieve Mass Production

By adopting advanced production equipment and technology, a large number of parts with the same specifications and performance can be produced in a short period of time. This scale effect can reduce production costs and improve the competitiveness of enterprises.

8. High Quality Stability

Modern mechanical processing equipment adopts advanced control systems and precise measurement technology, which can ensure that the size and shape of each component meet design requirements. This helps to improve the quality and performance of the product, while reducing the scrap rate.

In summary, mechanical parts processing has the characteristics of high efficiency, customization, batch production, quality stability, and material diversity. These characteristics make mechanical component processing occupy an important position in the manufacturing industry, providing strong support for the development of various industries.