When you want to create new parts or small batch production projects, you can use two manufacturing methods: CNC machining and 3D printing. Both of these options are essential for modern manufacturing processes. Each option has a roster of advantages over traditional manufacturing methods. Both are computerized manufacturing processes, while CNC machining and 3D printing are in the process. Production capacity and final product results are quite different.

Although these two processes sometimes produce similar results in specific applications, the way they obtain these results is quite different. Each process has been developed to meet different needs-so it is important to know which method best suits your needs. In the following, we introduce the advantages of each product to help you browse your next production order.

CNC Machining:

CNC machining is a common subtractive manufacturing technology. The process usually starts with a block of solid material, and then various sharp rotating tools or cutters are used to remove the material to achieve the desired final shape. It can be used for one-off small batch production and medium to batch production.

How it works

First, engineers use CAD or computer-aided software to make 2D or 3D models. Then, a computer-aided manufacturing (CAM) program is used to convert the CAD file into instructions. After the instruction is created, the post-processing program converts it into a specific command, and then transmits it to the CNC machine tool for execution, cutting out the required components from the bulk material. It has excellent repeatability, high precision, and a wide range of materials and surface finishes.

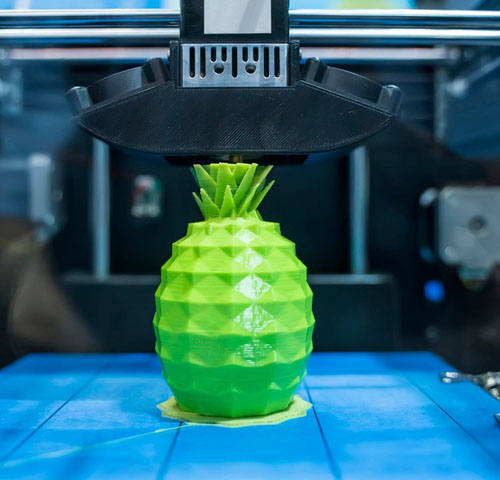

3D Printing

The additive manufacturing (AM) or 3D printing process builds parts by adding material one layer at a time. The AM process does not require special tools or fixtures, so the initial setup cost can be minimized.

3D printing has great uses in the medical field, which can create organs, prostheses and implants. The food industry also uses this technology to produce food by extruding the food layer by layer. Artists often use it to make art, while fashion designers use it to make clothing and jewelry.

How it works

First, engineers use CAD to make a 3D model. Errors in the finished model of the analysis usually include holes and intersecting faces.

Then, a program called a slicer turns the 3D printer into a series of thin 2D layers to prepare the model for the 3D printer, thereby generating G-code files. This file contains a set of instructions to be executed by the printer.

Next, a 3D printer reads the G code file and puts down one layer of material at a time to make a three-dimensional object. Depending on the size and complexity of the model and the method used, the printing process may last from hours to days. Sometimes, components may need to be cleaned, polished or sealed before they can be used.

Differences Between CNC Machining and 3D Printing

CNC machining and 3D printing have some basic things in common: for example, they are all based on 3D models and make 3D products in accordance with the instructions on the computer. They are compatible with STL and OBJ file types. In addition to these basic similarities, CNC machining and 3D printing can also meet different requirements and provide different benefits. But they still have many differences.

CNC machining and 3D printing have some basic things in common: for example, they are all based on 3D models and make 3D products in accordance with the instructions on the computer. They are compatible with STL and OBJ file types. In addition to these basic similarities, CNC machining and 3D printing can also meet different requirements and provide different benefits. But they still have many differences.

Material

CNC is mainly used for processing metal. It can also be used to process thermoplastics, acrylic, softwood and hardwood, modeling foam and processing wax. CNC precision parts are mainly used in engines, airplanes, production machinery and other high-strength environments.

3D printing is mainly used for plastics, while the use of metal is relatively small. Some techniques can produce parts from ceramics, wax, sand and composite materials. Materials that are difficult to process (such as TPU and metal super alloys) can be 3D printed. Compared with CNC parts, they may have smaller mechanical properties.

Most 3D printers use additive manufacturing processes to manufacture products from special plastics, resins, metals and other materials. Due to the unique materials used in the printing process, 3D parts usually do not have the strength required for use in harsh environments such as airplanes, vehicles, and production machinery.

Speed

Another major difference between CNC and additive manufacturing is speed. When mass producing products, CNC processing is faster because it involves the assembly line of the machine that produces each part. A 3D printer makes the entire product from start to finish, so it is not suitable for mass production. The additive process of 3D printing from scratch takes longer than the subtractive process of removing material from existing material blocks.

Precision

CNC machining has strict tolerances and excellent repeatability. Parts from large to small can be precisely CNC machined. Different 3D printing systems provide different dimensional accuracy. Industrial machinery can produce parts with very good tolerances. If tight gaps are needed, the key dimensions of 3D printing can be oversized and then processed in post-processing. The materials processed on CNC rolling mills (such as aluminum) are more accurate than FDM used in many 3D printers, and FDM tends to deform when exposed to excessive heat.

Parts Complexity

When designing CNC-machined parts, many restrictions must be considered. CNC machine tools cannot use certain geometries (even with 5-axis CNC systems) because the tool cannot access all surfaces of the part. Most geometric shapes require rotating parts to access different sides. Repositioning will increase processing and labor time, and may require custom fixtures and fixtures, which will affect the final price.

Compared with CNC, 3D printing has almost no geometric restrictions. Most technologies (such as FDM or SLM/DMLS) require supporting structures, and they are removed during post-processing.

Since no support is required, free-form organic organic geometric shapes can be easily manufactured through a polymer-based powder bed fusion process. The ability to produce highly complex geometric shapes is one of the key advantages of 3D printing. It also opens the door to part merging, in which multiple components can be combined into a part design to reduce the number of molds.

Waste

One of the main differences between additive manufacturing and subtractive manufacturing is the amount of waste they generate. Since CNC processing will take away materials, it will eventually produce a large amount of unrecyclable waste. The cleanup is a bit messy. However, there is less waste in 3D printing because the technology only requires the materials needed to build the workpiece. The 3D printer uses only the exact amount of material needed to make the part, so there is no need to clean up afterwards. 3D printers also produce less noise because they do not vibrate during production.

Application field

When manufacturing requires very strong, precise and/or heat-resistant workpieces, CNC milling is a better solution. 3D printing has more peculiar application areas: it can be used for bioprinting, food printing, construction purposes, and can be used in space.

Cost

When using a CNC machine to manufacture a part, a small amount usually brings a higher unit cost, but mass production becomes more and more economical. This makes CNC an ideal choice for mass production.

When using 3D printing, the output cost per unit is the same regardless of the batch size. When producing a small number of items, the equivalent cost per unit produced is an advantage, but when mass-produced, product consistency may become a problem.

Using CNC machines, the unit cost of the product will increase according to the complexity and accuracy of the output. The higher cost of complex CNC output is usually due to the larger number of tool paths required, the smaller number of tools used, and the amount of time required to complete these tasks. Regardless of the complexity of the unit produced, the cost of a 3D printing job is the same.

Conclusion

To some extent, CNC technology and 3D printing overlap in function, but their respective advantages make them suitable for special applications. It is like a pencil and a ballpoint pen. For some jobs, you need a pencil, but for other jobs, a ballpoint pen is a better tool. CNC machining are usually best suited for projects that require precise, high-precision products made from readily available materials. The characteristics of 3D printers make them very suitable for creating prototypes, visual basis and custom-designed products.

In summary, there is a lot of room for 3D printers and CNC machines in the world.