For mechanical machining, the concept of similarity is fatal. If a product that looks similar is used in combination with other products, the defects will continue to magnify, causing the processing quality of the factory to fail to meet the high-end precision manufacturing requirements. We all know that the problem of workpiece deformation in machining centers is more difficult to solve, so we must first analyze the reasons for the deformation, and then take countermeasures.

1. The material and structure of the workpiece affect the deformation

The amount of deformation is proportional to the complexity of the shape, aspect ratio and wall thickness, and proportional to the rigidity and stability of the material. Therefore, the influence of these factors on the deformation of the workpiece is reduced as much as possible when designing parts. Especially in the structure of large parts, the structure should be reasonable. Before processing, it is necessary to strictly control the defects such as the hardness and porosity of the blank to ensure the quality of the blank and reduce the deformation of the workpiece.

2. Deformation caused by workpiece clamping

The correct clamping point needs to be selected for the use of the fixture, and the appropriate clamping force is selected according to the position of the clamping point.

Make the clamping point and the support point as consistent as possible, so that the clamping force acts on the support, the clamping point should be as close as possible to the processing surface, and the selected position is not easy to cause clamping deformation.

When there are clamping forces in several directions on the workpiece, the order of clamping forces should be considered.

The clamping force should be applied first to make the workpiece and the support contact, and it is not easy to be too large, and the main clamping force that balances the cutting force should be applied later.

Increase the contact area between the workpiece and the fixture or use the axial clamping force.

Increasing the rigidity of the parts is an effective way to solve the clamping deformation, but due to the characteristics of the shape and structure of the thin-walled parts, it has a lower rigidity. In this way, under the action of clamping force, deformation will occur.

Enlarging the contact area between the workpiece and the fixture can effectively reduce the deformation of the workpiece during clamping.

For example, when milling thin-walled parts, a large number of elastic pressing plates are used to increase the force area of the contact parts; when turning the inner diameter and outer circle of the thin-walled sleeve, whether it is a simple split transition ring or an elastic mandrel , Full-arc jaws, etc., are used to increase the contact area when the workpiece is clamped. This method is conducive to bearing the clamping force, thereby avoiding the deformation of the parts.

Adopting axial clamping force, it is also widely used in production.

The design and manufacture of special fixtures can make the clamping force act on the end surface, which can solve the bending deformation of the workpiece due to the thin wall and poor rigidity of the workpiece.

3. The deformation caused by the processing of the workpiece

Due to the cutting force during the cutting process, the workpiece produces elastic deformation in the direction of the force, which is what we often call the phenomenon of giving up the knife. Corresponding measures should be taken on the tool to deal with this kind of deformation. The tool must be sharp during finishing. On the one hand, it can reduce the resistance caused by the friction between the tool and the workpiece, and on the other hand, it can improve the heat dissipation capacity of the tool when cutting the workpiece, thereby reducing the workpiece. The residual internal stress.

For example, when milling large planes of thin-walled parts, single-edge milling is used.

The tool parameters choose a larger entering angle and a larger rake angle, the purpose is to reduce the cutting resistance. Because this kind of tool cuts lightly and reduces the deformation of thin-walled parts, it is widely used in production. In the turning of thin-walled parts, a reasonable tool angle is very important to the cutting force during turning, the thermal deformation generated during turning, and the microscopic quality of the workpiece surface. The size of the rake angle of the tool determines the cutting deformation and the sharpness of the rake angle of the tool. Large rake angles reduce cutting deformation and friction, but too large rake angles will reduce the wedge angle of the tool, weaken the tool strength, poor heat dissipation of the tool, and accelerate wear.

Generally, when turning thin-walled parts of steel materials, use high-speed tools with a rake angle of 6°~30°, and a cemented carbide tool with a rake angle of 5°~20°. The clearance angle of the tool is large, the friction is small, and the cutting force is correspondingly reduced, but too large clearance angle will also weaken the strength of the tool. When turning thin-walled parts, use high-speed steel turning tools, the tool clearance angle is 6°~12°, with cemented carbide tools, the clearance angle is 4°~12°, and the larger clearance angle is used for fine turning. When taking the smaller back angle. When turning the inner and outer circles of thin-walled parts, taking a large entering angle and choosing the correct tool is a necessary condition for coping with the deformation of the workpiece.

The heat generated by the friction between the tool and the workpiece will also deform the workpiece during processing, so high-speed cutting is often selected.

In high-speed machining, since the chips are removed in a relatively short time, most of the cutting heat is taken away by the chips, reducing the thermal deformation of the workpiece; secondly, in high-speed machining, the softening of the cutting layer material is also reduced. It can reduce the deformation of parts processing and help ensure the accuracy of the size and shape of the parts. In addition, the cutting fluid is mainly used to reduce friction during the cutting process and lower the cutting temperature. The rational use of cutting fluid plays an important role in improving the durability of the tool, the quality of the processed surface, and the accuracy of the processing. Therefore, in order to prevent parts from deforming, sufficient cutting fluid must be used reasonably.

The use of reasonable cutting amount in processing is a key factor to ensure the accuracy of parts.

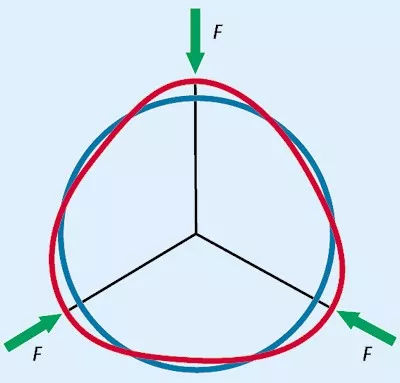

When processing thin-walled parts with high precision requirements, symmetrical processing is generally adopted to balance the stresses generated on the two opposite sides to a stable state, and the workpiece is smooth after processing. However, when a large amount of knife is taken in a certain process, the workpiece will be deformed due to the loss of balance between tensile stress and compressive stress.

The deformation of thin-walled parts during turning is multifaceted. The clamping force when clamping the workpiece, the cutting force when cutting the workpiece, and the elastic deformation and plastic deformation generated when the workpiece hinders the tool cutting, increase the temperature of the cutting zone and produce thermal deformation. Therefore, when we are roughing, the amount of back-grabbing and feed can be larger; for finishing, the amount of knife is generally 0.2~0.5mm, and the amount of feed is generally 0.1~0.2mm/r, or even smaller , The cutting speed is 6~120m/min, and the cutting speed is as high as possible when finishing turning, but it is not easy to be too high. Choose a reasonable amount of cutting, so as to achieve the purpose of reducing part deformation.

4. Stress and deformation after processing

After processing, the part itself has internal stress. These internal stress distributions are in a relatively balanced state. The shape of the part is relatively stable. However, the internal stress changes after removing some materials and heat treatment. At this time, the workpiece needs to reach the balance of force again, so the shape is Has changed.

To solve this kind of deformation, heat treatment can be used to stack the workpiece to be straightened to a certain height, use a certain tooling to compact it into a straight state, and then put the tooling and the workpiece into the heating furnace together. Choose according to the different materials of the parts. Different heating temperature and heating time.

After hot straightening, the internal organization of the workpiece is stable. At this time, the workpiece not only has a higher straightness, but also the work hardening phenomenon is eliminated, which is more convenient for further finishing of the parts. Castings should be aging treatment, try to eliminate internal residual stress, and use the method of deforming and then processing, that is, rough processing-aging-reprocessing.

For large parts, it is necessary to use profiling processing, that is, predict the deformation of the workpiece after assembly, and reserve the deformation in the opposite direction during machining, which can effectively prevent the deformation of the parts after assembly.

In summary, for easily deformable workpieces, corresponding countermeasures must be adopted in the blank and processing technology. It is necessary to analyze different situations and find a suitable process route. Of course, the above method only further reduces the deformation of the workpiece. If you want to obtain a more precise workpiece, you still need to continue learning, discussion and research.