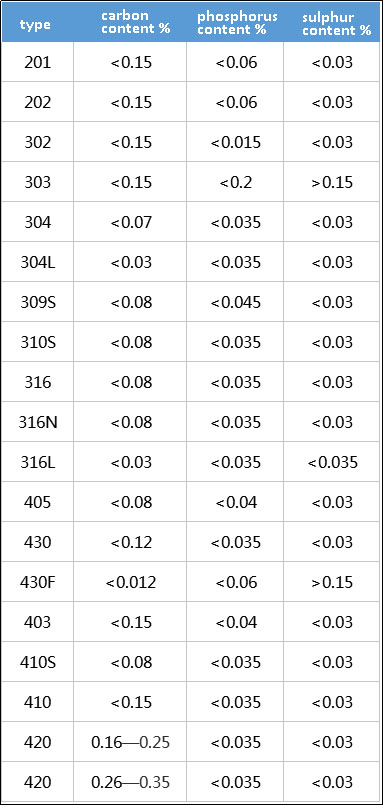

Sulfur and phosphorus content is a very important index for stainless steel, according to which carbon structural steel and high-quality carbon structural steel are divided:

Steel with sulfur and phosphorus content less than 0.04% is called high-quality steel. Steel with sulfur content not more than 0.03% and phosphorus content not more than 0.035% is called high-quality steel; Steel with sulfur and phosphorus content not more than 0.025% is called super quality steel.

Common sulfur and phosphorus contents of stainless steel are as follows:

Common Stainless Steel Type

Common stainless steel models are usually represented by numerical symbols, including 200 series, 300 series and 400 series, which are American representations, such as 201,202,303,304,316,410,420,430. Chinese stainless steel models are represented by element symbols plus numbers, such as 1Cr18Ni9, 0Cr18Ni9, 00cr18ni9, 1Cr17, 3Cr13, 1Cr17Mn6Ni5N, etc., and numbers represent the corresponding element content.

200 Series: chromium nickel manganese austenitic stainless steel

300 series: chromium nickel austenitic stainless steel

301: good ductility, used for molding products. It can also be hardened by machine speed. Good weldability. The wear resistance and fatigue strength are better than 304 stainless steel.

302: the corrosion resistance is the same as 304, and the strength is better due to the relatively high carbon content.

302B: it is a stainless steel with high silicon content. It has high resistance to high temperature oxidation.

303: a small amount of sulfur and phosphorus is added to make it easier to cut.

303se: it is also used to make mechanical parts requiring hot heading, because this stainless steel has good hot workability under such conditions.

304: 18/8 stainless steel. The GB brand is 0Cr18Ni9. 309: better temperature resistance than 304.

304L: it is a variant of 304 stainless steel with low carbon content. It is used for occasions requiring welding. The low carbon content minimizes the precipitation of carbides in the heat affected zone near the weld, and the precipitation of carbides may lead to intergranular corrosion (welding corrosion) of stainless steel in some environments.

304n: it is a kind of stainless steel containing nitrogen. Nitrogen is added to improve the strength of steel.

305 and 384: it contains high nickel and has low work hardening rate. It is suitable for various occasions requiring high cold formability.

308: used for making welding rod.

309, 310, 314 and 330: the contents of nickel and chromium are relatively high in order to improve the oxidation resistance and creep strength of steel at high temperature. 30s5 and 310S are variants of 309 and 310 stainless steel. The difference is that the carbon content is low, so as to minimize the carbide precipitated near the weld. 330 stainless steel has particularly high carburization resistance and thermal shock resistance.

316 and 317: containing aluminum, the resistance to pitting corrosion in marine and chemical industrial environments is much better than that of 304 stainless steel. Among them, the variants of type 316 stainless steel include low-carbon stainless steel 316L, nitrogen-containing high-strength stainless steel 316N and free cutting stainless steel 316F with high sulfur content.

321, 347 and 348: stainless steel stabilized with titanium, niobium plus tantalum and niobium respectively, suitable for welding components at high temperature. 348 is a kind of stainless steel suitable for nuclear power industry, which has certain restrictions on the amount of tantalum and drill.

400 series: Ferritic and martensitic stainless steel

408: good heat resistance, weak corrosion resistance, 11% Cr, 8% Ni

409: the cheapest model (British and American), usually used as automobile exhaust pipe, belonging to ferritic stainless steel (chromium steel)

410: martensite (high strength chromium steel), with good wear resistance and poor corrosion resistance. 416: sulfur is added to improve the processability of the material.

420: “cutting tool grade” martensitic steel, the earliest stainless steel like Brinell high chromium steel. It is also used for surgical knives, which can be made very bright

430: ferritic stainless steel, used for decoration, such as automobile accessories. Good formability, but poor temperature resistance and corrosion resistance

440: high strength cutting tool steel, with slightly higher carbon content, can obtain higher yield strength after proper heat treatment, and the hardness can reach 58hrc, which is one of the hardest stainless steels. The most common application example is “razor blade”. There are three common models: 440A, 440b, 440C, and 440f (easy to process)

500 Series: heat resistant chromium alloy steel

600 Series: Martensitic precipitation hardening stainless steel

630: the most commonly used precipitation hardening stainless steel model, usually also called 17-4; 17%Cr,4%Ni