When creating parts for aerospace applications, many factors need to be considered, such as the shape, weight, and durability of the part. These factors will affect the flight value of the aircraft. For many years, the material of choice for aerospace applications has been aluminum. However, in modern jet aircraft, it only accounts for 20% of the structure.

However, due to the demand for light aircraft, the use of composite materials such as carbon-reinforced polymers and honeycomb materials continues to increase in the modern aerospace industry. In recent years, aerospace manufacturers have begun to study alternatives to aluminum, one of which is aerospace-grade stainless steel. The use of this stainless steel in new aircraft components has increased. This post will explain the usage and difference between aluminum and stainless steel in modern aircraft.

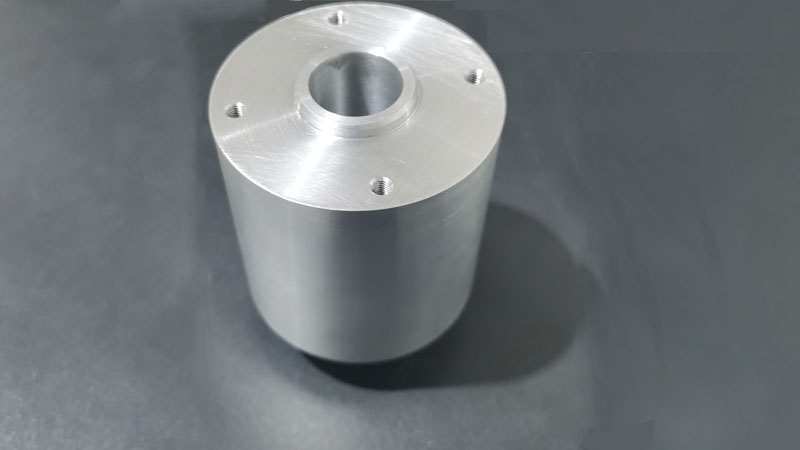

Aluminum Parts for Aerospace Applications

Aluminum is a relatively lightweight material, weighing approximately 2.7 g/cm3 (grams per cubic centimeter). Although aluminum is lighter and cheaper than stainless steel, aluminum is not as strong and corrosion resistant as stainless steel. In terms of durability and strength, stainless steel is superior to aluminum.

Although the use of aluminum has declined in many aspects of aerospace production, aluminum is still widely used in modern aircraft. For many specific purposes, aluminum is still the strongest and lightest material. Due to its high ductility, it is easy to process and it is relatively cheap compared to many composite materials or titanium. It can also be further enhanced by alloying it with other metals (such as copper, magnesium, manganese, and zinc) or by cold or heat treatment. When aluminum is exposed to the air, the close chemical oxide bonds isolate the aluminum from the environment. This feature makes it extremely resistant to corrosion.

The most popular aluminum alloys used in the manufacture of aerospace parts include:

- Aluminum alloy 7075 (aluminum/zinc)

- Aluminum alloy 7475-02 (aluminum/zinc/magnesium/silicon/chromium)

- Aluminum alloy 6061 (aluminum/magnesium/silicon)

7075 is a combination of aluminum and zinc and is the most commonly used alloy in aerospace applications with excellent mechanical properties, ductility, strength and fatigue resistance.

7475-02 is a combination of aluminum, zinc, silicon and chromium, while 6061 contains aluminum, magnesium and silicon. Which alloy is required depends entirely on the intended application of the end part. Although many aluminum aircraft parts are purely decorative, certain parts are essential to the function of the aircraft and must have specific characteristics.

A common type of aluminum alloy used in the aerospace industry is aluminum-scandium. The addition of scandium to aluminum bolsters the metal’s strength and ability to resist heat. The use of aluminum-scandium can also increase fuel efficiency. As it is an alternative to denser materials such as steel and titanium, replacement of these with lighter aluminum-scandium leads to weight reduction which in turn provides greater fuel efficiency.

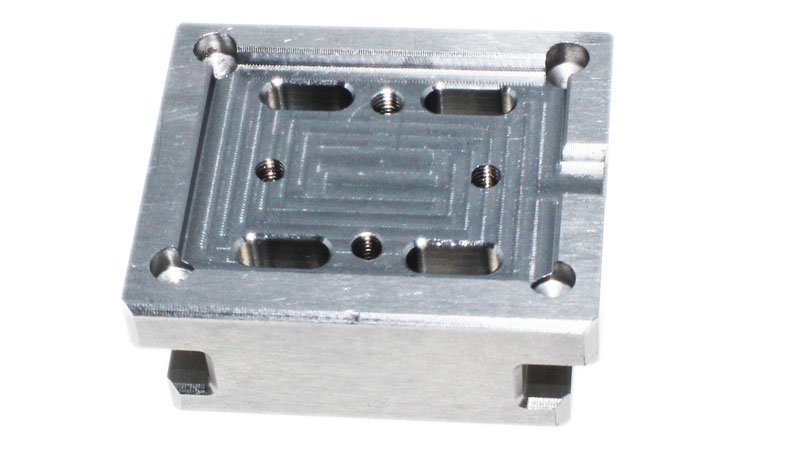

Stainless Steel Parts for Aerospace Applications

In the aerospace industry, stainless steel seems to be a surprising choice compared to aluminum. Although stainless steel has a greater weight, it has recently been found to increase its use in aerospace applications.

Stainless steel refers to the iron-based alloy family containing at least 11% chromium, which is a compound that prevents iron corrosion and provides heat resistance. Different types of stainless steel include the elements nitrogen, aluminum, silicon, sulfur, titanium, nickel, copper, selenium, niobium and molybdenum. The type of stainless steel has been graded and represented by three digits. Although the frequently used stainless steel is only about one tenth, there are more than 150 stainless steel grades. In addition, stainless steel can be formed into thin plates, plates, bars, wires, and tubes, making it useful for a variety of applications. There are five main stainless steel groups, mainly classified by their crystal structure. These groups are austenitic, ferrite, martensite, duplex and precipitation hardening stainless steels.

As mentioned above, stainless steel is an alloy made by a combination of steel and chromium. The strength of stainless steel is directly related to the content of chromium in the alloy. The higher the chromium content, the stronger the steel. The use of stainless steel alloys has been found to increase in aircraft components that require high strength but can cope with the increased weight. Stainless steel has high corrosion resistance and high temperature resistance, making it suitable for a range of aerospace components, including actuators, fasteners and landing gear components.

Advantages:

Although stronger than aluminum, stainless steel is usually much heavier. However, compared with aluminum, stainless steel parts have two main advantages:

Stainless Steel Has High Corrosion Resistance.

The resistance of stainless steel to iron trioxide is due to the presence of chromium in the alloy, which forms a passivation film to protect the material from corrosion. Whether it comes from atmospheric conditions or chemical solvents, stainless steel has high corrosion resistance. Due to its protective oxide layer, stainless steel prevents oxidation and corrosion. In fact, when exposed to oxygen, the membrane can actually repair itself. Corrosion and pollution resistance, low maintenance costs, and familiar gloss make stainless steel a common material in applications that require strength and corrosion resistance.

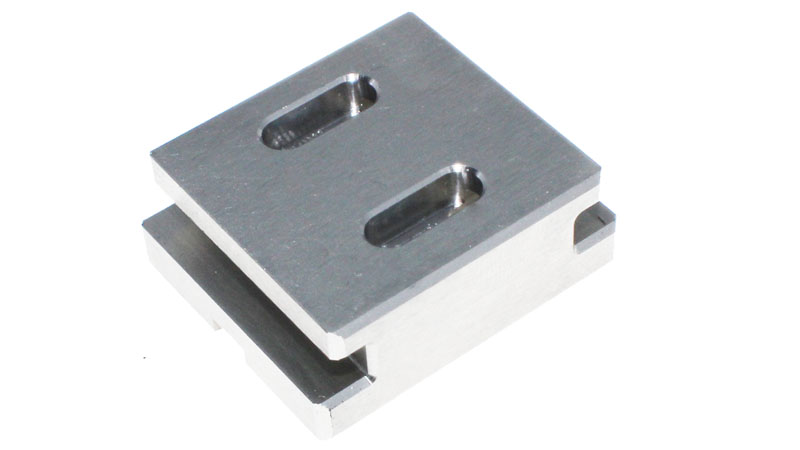

Stainless Steel Is Stronger And More Resistant To Wear.

Stainless steel has a higher tensile strength than aluminum and can better withstand stress, vibration, scratches, impact and damage. For example, the ultimate tensile strength of grade 304 stainless steel is higher than that of aluminum, at 505 MPa (73,200 psi) and 310 MPa (45,000 psi) respectively.

The Shear Modulus And Melting Point Of Stainless Steel Are Also Higher Than That Of Aluminum.

These characteristics are essential for many aerospace parts and make stainless steel parts a versatile choice for aerospace applications.

Other advantages of stainless steel include its excellent heat resistance and fire resistance, bright, beautiful appearance, and excellent hygienic qualities. Stainless steel is also easy to manufacture, which is an important consideration when all parts of the aircraft must be welded, machined or cut to precise specifications. Finally, certain stainless steel alloys have extremely high impact resistance, which is an important factor in the safety and durability of large aircraft.

Conclusion

With the passage of time, the aerospace industry has become more and more diverse, and modern aerospace vehicles are more likely to be manufactured with stainless steel fuselage or airframe. Despite the higher price, they are also much stronger than aluminum, and depending on the grade used, can still provide an excellent strength-to-weight ratio.

Whether you are looking for high-quality aluminum aircraft or stainless steel aircraft parts, we can provide the parts you need. we can help you find all types of aluminum and stainless steel aircraft parts and deliver them with short lead times and competitive prices. For a quick and competitive quote, email us at info@sansmachining.com.