1. The Principle Of Maximum Concentration Of Processes And One-time Positioning

Generally on CNC machine tools, especially on the machining center, the processing of parts and procedures can be concentrated to the greatest extent, that is, the parts should be completed as much as possible in a clamping, most or all of the procedures that can be processed by this CNC machine tool. Concentration of processes can reduce the number of machine tools and the number of workpiece clamping times, reduce unnecessary positioning errors, and increase productivity. For the processing of the hole system with high coaxiality, all the processing of the coaxial hole system should be completed by sequential and continuous tool change after one installation, and then the holes in other positions should be processed to eliminate the influence of repeated positioning errors. Improve the coaxiality of the hole system.

2. The Principle Of Rough First And Refined

When performing numerical control processing, when dividing processes according to elements such as machining accuracy, rigidity and deformation of the parts, the processes should be divided according to the separation of roughing and finishing, that is, semi-finishing and finishing are performed after all roughing is completed. For a certain machined surface, it should be finished in the order of roughing-semi-finishing-finishing. When roughing, it is necessary to give full play to the performance of the machine tool and the cutting performance of the tool under the conditions of ensuring the quality of the processing, the durability of the tool and the rigidity of the machine tool-fixture-tool-workpiece process system, and try to use a larger number of cuts. Obtain the processing conditions with the margins of each part before finishing as uniform as possible. During finishing, the machining accuracy and surface quality of the parts are mainly ensured. Therefore, the final contour of the parts during finishing should be continuously finished by the last cut. In order to ensure the processing quality, under normal circumstances, the fine machining allowance should be 0.2-0.6mm. It is better to leave a period of time between roughing and finishing, so that the deformation of the parts after roughing can be fully restored before finishing. Processing to improve the processing accuracy of parts.

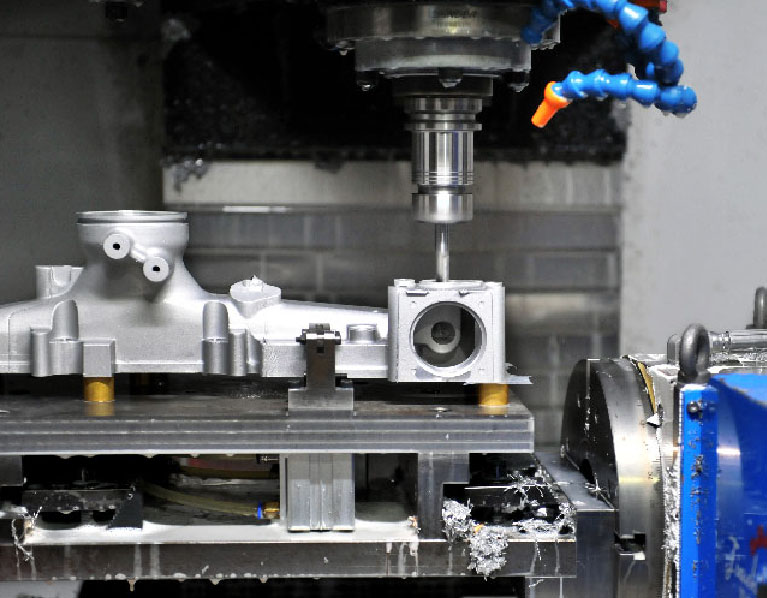

3. The Principle Of Near First, Far Away, Face Before Hole

According to the distance between the processing part and the tool setting point, under normal circumstances, the part close to the tool setting point is processed first, and the part far away from the tool setting point is processed later in order to shorten the tool movement distance and reduce the idle travel time. For turning, first near and farther also helps to maintain the rigidity of the blank or semi-finished product and improve its cutting conditions. For the machining of parts with both milling planes and boring holes, the order of milling planes and then boring holes can be carried out. Because the cutting force is large when milling the plane, the parts are prone to deformation. First, mill the face and then boring, so that it can recover for a period of time. After the deformation is restored, boring is helpful to ensure the machining accuracy of the hole. Secondly, if boring first When the plane is milled after the hole, burrs and burrs will be generated at the hole, which will affect the assembly of the hole.