3 Methods Of Thread Machining On CNC Machining Center

Everyone has an in-depth understanding of the benefits of using a CNC machining center to process workpieces. Today, I will share with you the thread processing methods. There are 3 methods for thread machining by CNC machining center: thread milling, tap machining, and picking machining.

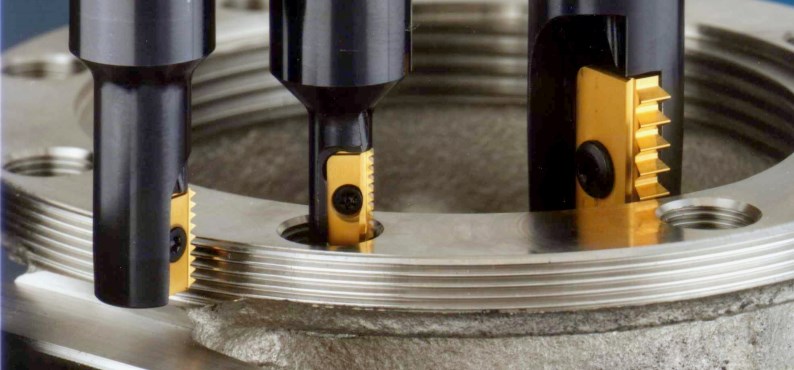

1. Thread Milling Method

Thread milling is the use of thread milling tools for the processing of large-hole threads, as well as the processing of threaded holes of difficult-to-machine materials. It has the following characteristics:

- The tool is generally made of hard alloy material, which has high speed, high precision of milling thread and high processing efficiency.

- With the same pitch, no matter whether it is a left-handed thread or a right-handed thread, one tool can be used, which reduces the cost of the tool.

- The thread milling method is especially suitable for the thread processing of stainless steel, copper and other difficult-to-process materials. It is easy to remove chips and cool, and can ensure the quality and safety of processing.

- There is no tool front guide, it is more convenient to process blind holes with short threaded bottom holes or holes without undercuts.

Thread milling tools are divided into two types: machine-clamped cemented carbide blade milling cutters and integral cemented carbide milling cutters. Machine-clamped tools can process holes with a thread depth less than the length of the blade, and can also process holes with a thread depth greater than the length of the blade. Hole, and the integral carbide milling cutter is used to machine the hole whose thread depth is less than the tool length.

Note for thread milling CNC programming: so as not to cause damage to the tool or processing errors.

- After processing the threaded bottom hole, use a drill to machine a small diameter hole, and use boring to machine a larger hole to ensure the accuracy of the threaded bottom hole.

- The tool generally uses a 1/2 circle arc path to cut in and out to ensure the thread shape, and the tool radius compensation value should be brought in at this time.

2. Tap Machining Method

Suitable for threaded holes with small diameters or low hole position accuracy requirements. Generally, the diameter of the threaded bottom hole drill is close to the upper limit of the threaded bottom hole diameter tolerance, which can reduce the machining allowance of the tap and reduce the load of the tap. Improve the service life of the tap.

Everyone should choose the appropriate tap according to the material to be processed. Compared with the milling cutter and boring cutter, the tap is very sensitive to the processed material. Taps are divided into through-hole taps and blind-hole taps. The leading end of the through-hole tap is long, which is the front chip removal. When the blind hole is processed, the processing depth of the thread cannot be guaranteed. Pay attention to the difference between the two. When using a flexible tapping chuck, note that the diameter of the tap shank and the width of the square should be the same as that of the tapping chuck. The diameter of the shank of the tap for rigid tapping should be the same as the diameter of the spring collet.

The programming of tap processing method is relatively simple, all are in fixed mode, just add parameter value, it should be noted that the format of the subroutine is different for different CNC systems, and the representative meaning of the parameter value is different.

3. Pick Machining Method

The picking method is suitable for the processing of large threaded holes on box parts, or when there is no tap and thread milling cutter, this method is used to install a thread turning tool on the boring bar to perform thread boring. There are several precautions for implementing the pick and button processing method:

- There must be a delay time for starting the spindle to ensure that the spindle reaches the rated speed.

- The sharpening of hand-grinding thread tools cannot be symmetrical, and reverse retraction cannot be used. The spindle should be used to orient the cutter to move radially and then retract.

- The tool holder must be accurate and consistent with the position of the tool slot, otherwise multiple tool holders cannot be used for machining, which will cause random snapping.

- When picking the buckle, be careful not to pick it with one knife, even a very thin buckle, otherwise it will cause tooth loss and poor surface roughness, so you should divide it into multiple knives for picking.

- The buckle processing method is only suitable for single pieces, small batches, special pitch threads and no corresponding tools, and the processing efficiency is low.

The buckle machining method of the CNC machining center is only a temporary emergency method. It is recommended that you use the thread machining method to process the tool to effectively improve the efficiency and quality of thread machining, reduce the processing cost and improve the efficiency of the machining center.