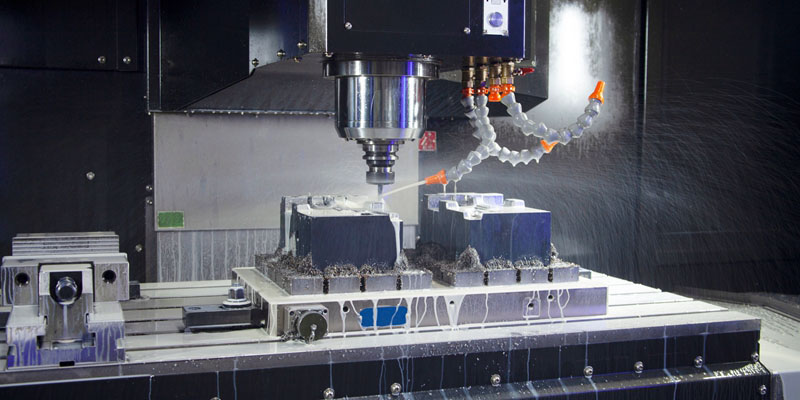

With a variety of processing technologies appearing on the market, they are gradually known or recognized by us. In the industry, CNC machining is still a processing technology that is used more often. However, according to many users, machining allowances are left on CNC machining parts during production. Why do they do this?

The thickness of the metal layer removed in each process of CNC machining is called the machining allowance between processes. For torsional surfaces such as outer circles and holes, the machining allowance is considered from the diameter, so it is called a symmetrical allowance (ie, both sides allowance), that is, the actual thickness of the metal layer removed is the addition of the machining allowance on the diameter. Half. The machining allowance of the plane is the unilateral allowance, which is the actual thickness of the metal layer removed.

The goal of leaving a machining allowance on the workpiece is to remove the machining errors and external defects left by the previous process, such as the chill layer, pores, sand inclusion layer on the outside of the casting, oxide scale, decarburization layer, and external cracks on the outside of the forging. , the internal stress layer and surface roughness after cutting. Then improve the accuracy and surface roughness of the workpiece. The size of the machining allowance has a great influence on the machining quality and production efficiency.

Excessive machining allowance not only increases the labor of machining and reduces productivity, but also increases the consumption of materials, objects and power, and CNC machining increases the processing cost. If the machining allowance is too small, it is too late to eliminate all kinds of defects and errors in the previous process, and it is too late to compensate for the clamping error during processing in this process, resulting in waste products. The principle is to make the allowance as small as possible under the condition of ensuring the quality of CNC machining. Generally speaking, the more finishing, the smaller the process allowance.

When determining the CNC machining sequence, it is also necessary to clarify whether the parts are to be pre-machined before machining. Pre-machining is often completed by ordinary machine tools. If the precision of the blank is high, the positioning is more reliable, or the machining allowance is sufficient and uniform, it can be processed directly on the CNC machine tool without pre-processing. At this time, the distinction of CNC machine tool processes should be considered according to the accuracy of the rough rough reference, so one process or several processes to complete.

The above reasons for leaving machining allowance on CNC machined parts are shared here. The CNC machined parts skill is to use superhard materials and greatly increase the cutting speed and feed rate to improve the material removal rate, machining accuracy and machining quality. With modern machining skills, the cutting speed limit of precision machining varies with workpiece materials and cutting methods.