Custom machined parts have become an essential component of modern industrial processes, providing a wide range of benefits, including precision, cost-effectiveness, flexibility, improved efficiency, enhanced safety, improved performance, and greater innovation. As a result, they are used across various industries, from manufacturing and aerospace to medical and automotive. In this post, we will explore the top 10 industries that rely on custom machined parts.

Manufacturing

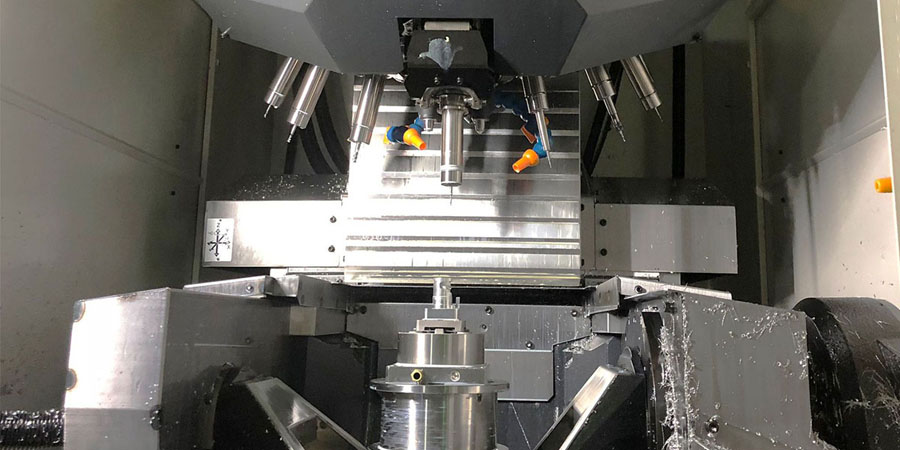

The manufacturing industry is one of the primary users of custom machined parts. These parts are essential for the production of machinery, equipment, and tools used in various manufacturing processes. Custom machined parts can be designed to meet the precise requirements of each application, improving the efficiency, reliability, and safety of manufacturing operations.

Aerospace

The aerospace industry demands high levels of precision and accuracy, making custom machined parts critical for aircraft and spacecraft manufacturing. These parts must meet stringent specifications and tolerances to ensure that they perform optimally under extreme conditions, including high-speed flight, extreme temperatures, and exposure to corrosive substances.

Medical

Custom machined parts are used extensively in the medical industry, particularly in the production of medical devices and equipment. These parts must meet strict regulatory standards and be designed to function in a range of medical environments, including sterile environments and surgical procedures.

Automotive

The automotive industry is another significant user of custom machined parts, particularly for the production of engines, transmissions, and other critical components. These parts must meet exact specifications and tolerances to ensure optimal performance, safety, and efficiency.

Oil and Gas

The oil and gas industry relies heavily on custom machined parts for the production, transportation, and distribution of oil and gas products. These parts must be engineered to withstand extreme conditions, including high pressures and temperatures, corrosive substances, and harsh environmental factors.

Construction

The construction industry utilizes custom machined parts in the production of heavy machinery and equipment, including cranes, excavators, and bulldozers. These parts must be designed to withstand heavy loads and repetitive stress, ensuring that they perform optimally in demanding construction environments.

Electronics

The electronics industry requires custom machined parts for the production of electronic components and devices, including printed circuit boards, computer components, and telecommunications equipment. These parts must be designed to function optimally in a range of electronic environments, including high-speed data transmission, electromagnetic interference, and other challenging conditions.

Energy

The energy industry utilizes custom machined parts in the production of power generation equipment, including turbines, generators, and other critical components. These parts must be designed to meet exact specifications and tolerances, ensuring optimal efficiency, reliability, and safety in the production and distribution of energy products.

Defense

The defense industry relies on custom machined parts for the production of military equipment, including aircraft, ships, vehicles, and weapons. These parts must meet stringent specifications and be designed to function optimally in extreme environments and conditions.

Agriculture

The agriculture industry utilizes custom machined parts in the production of agricultural machinery and equipment, including tractors, harvesters, and other critical components. These parts must be designed to withstand repetitive stress and harsh environmental conditions, ensuring optimal performance in demanding agricultural environments.

In conclusion, custom machined parts are essential components of various industries, providing precision, cost-effectiveness, flexibility, improved efficiency, enhanced safety, improved performance, and greater innovation. By partnering with experienced manufacturers who specialize in custom machined parts, companies can optimize the design, functionality, and performance of their equipment and machinery, enabling them to meet their unique needs and requirements. With the increasing demand for advanced manufacturing and industrial processes, custom machined parts are likely to play an even more critical role in the future of industrial automation and production.