In the process of cutting, the thin wall is easy to deform due to the cutting force, which leads to the “waist” phenomenon of ellipse or small in the middle and large at both ends. In addition, due to poor heat dissipation during processing, thin-walled casing is very easy to produce thermal deformation, which is difficult to ensure the processing quality of parts. The following parts are not only inconvenient to clamp, but also difficult to process, so a special thin-walled casing and guard shaft shall be designed.

Process Analysis

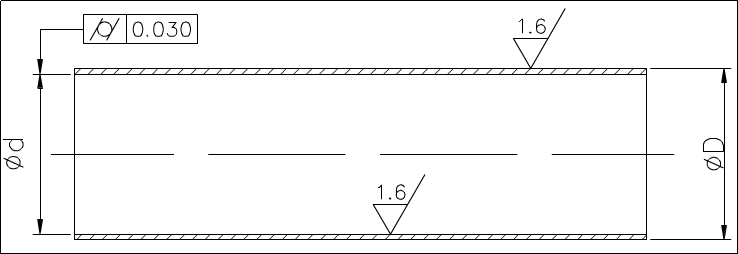

According to the technical requirements provided in the drawing, the workpiece is processed with seamless steel pipe, and the surface roughness of the inner hole and outer wall is Ra1.6 μ m. It can be achieved by turning, but the cylindricity of the inner hole is 0.03mm, which requires high requirements for thin-walled parts. In batch production, the process route is roughly as follows: blanking – heat treatment – turning end face – turning excircle – turning bore – quality inspection.

“Inner hole processing” process is the key to quality control. It is difficult to ensure a 0.03mm cylinder when cutting the inner hole without excircle and thin-walled casing.

Key Technology Of Turning Hole

The key technology of turning holes is to solve the problems of rigidity and chip removal of inner hole turning tools. The following measures shall be taken to increase the rigidity of the inner hole turning tool:

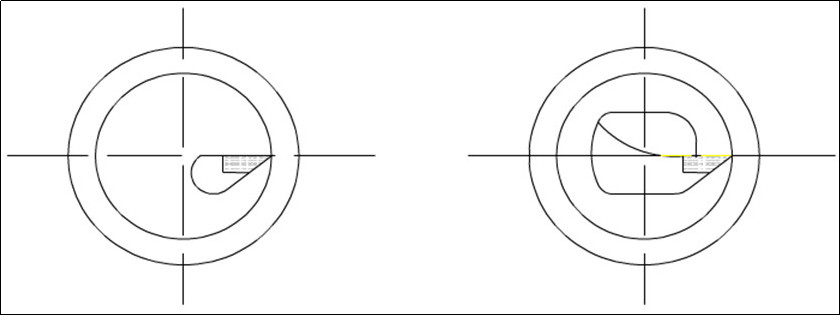

1. Increase the sectional area of the tool handle as much as possible. Generally, the tip of the inner hole turning tool is located above the tool handle, so the sectional area of the tool handle is less than 1/4 of the hole sectional area, as shown in the left figure below. If the tip of the inner hole turning tool is located on the centerline of the tool handle, the sectional area of the tool handle in the hole can be greatly increased, as shown in the right figure below.

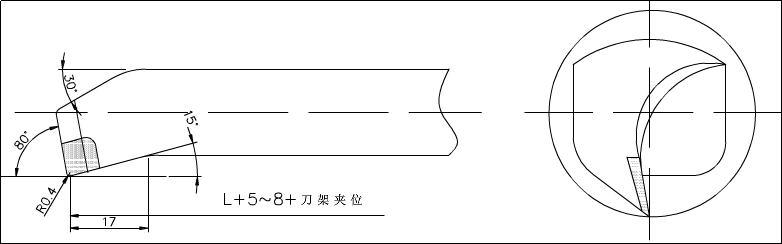

2. The extended length of the tool handle shall be 5-8mm as long as possible with the length of the workpiece to increase the rigidity of the tool handle and reduce the vibration in the cutting process.

Solve The Problem Of Chip Removal

It mainly controls the cutting flow direction. The rough turning tool requires that the chip flow to the surface to be machined (front chip). Therefore, the inner hole turning tool with positive edge inclination is used, as shown in the following figure.

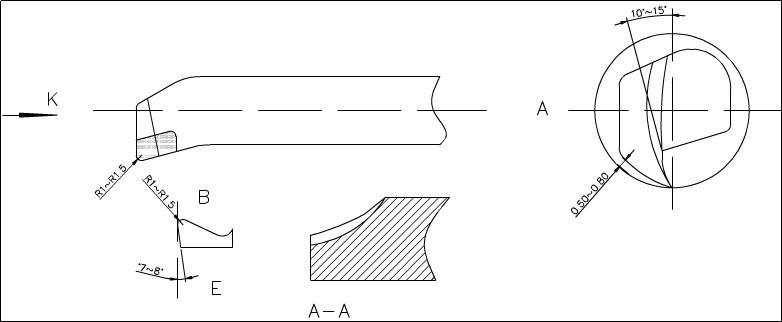

During fine turning, the chip flow direction is required to tilt the front chip toward the center (hole center chip removal). Therefore, the grinding direction of the cutting edge should be paid attention to when sharpening the tool. The chip removal method should be forward along the inclined arc. As shown in the figure below, the fine turning tool alloy YA6, the current M type, has good bending strength, wear resistance, impact toughness, and resistance to adhesion and temperature with steel.

When grinding, the front angle is rounded to an arc angle of 10-15 °, and the rear angle is 0.5-0.8mm away from the wall according to the processing arc (along the arc of the tool bottom line). The cutting edge angle of c is § 0.5-1 in the k direction, which is R1-1.5 along the point B of the chip edge. The secondary rear angle is appropriate to be grinded to 7-8 °. The point A-A of the inner edge of E is grinded into a circle to discharge chips outward.

Processing Method

1) A shaft guard must be made before processing. The main purpose of shaft guard is to cover the turned inner hole of the thin wall sleeve with the original size, and fix it with the front and rear centers so that it can process the outer circle without deformation, and maintain the processing quality and accuracy of the outer circle. Therefore, the processing of the protecting shaft is the key link for the processing of the thin-walled casing.

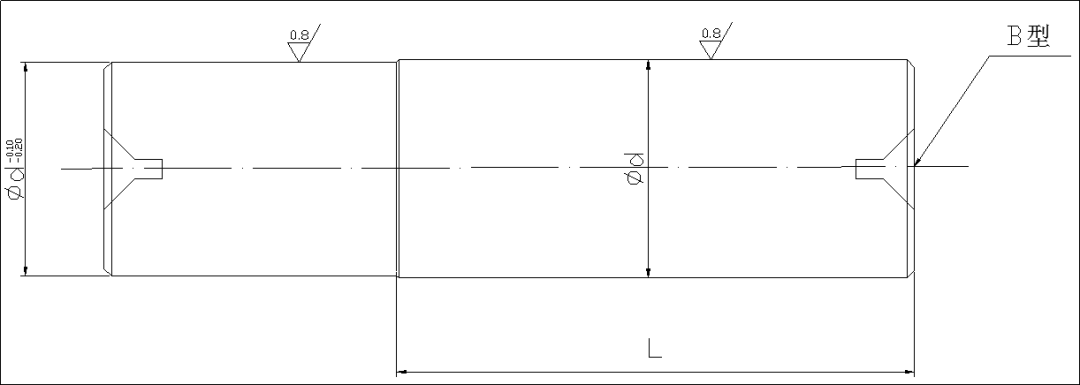

45#carbon structural round steel for processing guard shaft rough embryo; Turn the end face, open the B-type center holes at both ends, rough the excircle, and leave 1mm margin. After heat treatment, quenching and tempering, shaping, and fine turning, 0.2mm allowance shall be left for grinding. The surface of crushed fire shall be heat treated again, with hardness of HRC50, and then ground by cylindrical grinder as shown in the figure below. The accuracy shall meet the requirements and shall be ready for use after completion.

2) In order to finish the processing of the workpiece at one time, the clamping position and cutting allowance shall be reserved for the rough embryo.

3) First, the hair germ is heat treated, tempered and shaped, and the hardness is HRC28-30 (the hardness within the machinable range).

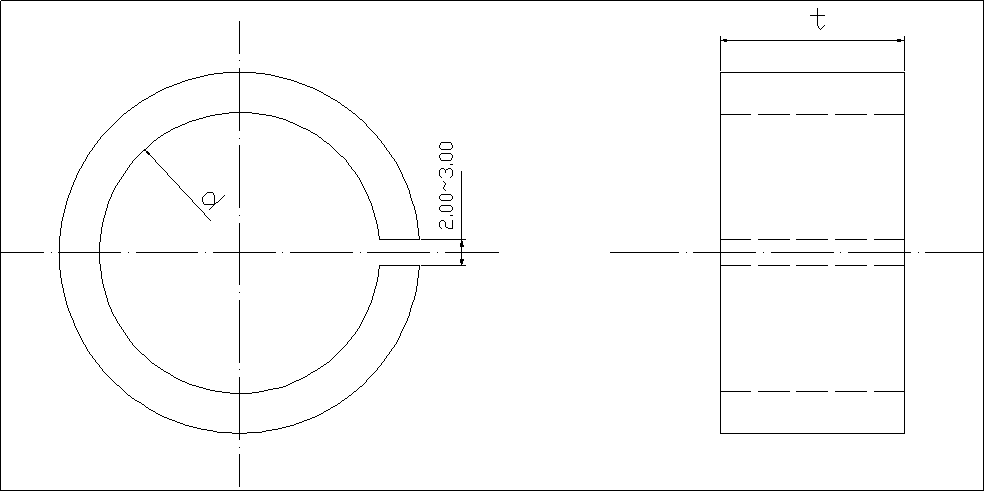

4)The turning tool adopts C620. First, put the front center into the spindle cone to fix it. To prevent the workpiece from deformation when clamping the thin-walled sleeve, add an open-loop thick sleeve, as shown in the following figure.

In order to maintain mass production, one end of the outer circle of the thin wall casing is processed to a uniform size d, and the ruler t is axially clamped, and the thin wall casing is compressed to improve the quality when turning the inner hole and maintain the size. Considering the cutting heat, it is difficult to master the expansion size of the workpiece. Sufficient cutting fluid shall be poured to reduce the thermal deformation of the workpiece.

5) Clamp the workpiece with automatic centering three jaw chuck, turn the end face and rough the inner circle. The allowance is 0.1-0.2mm for fine turning, and the fine turning tool is replaced to process the cutting allowance to meet the requirements of excessive fit and roughness of the guard shaft. Remove the inner hole turning tool, insert the guard shaft to the front center, clamp it with the tailstock center according to the length requirements, change the outer circle turning tool to rough the outer circle, and then finish turning to meet the drawing requirements. After passing the inspection, use the cutting knife to cut according to the required length. In order to make the cut smooth when the workpiece is disconnected, the cutting edge shall be grinded obliquely to make the end face of the workpiece smooth; The small section of the guard shaft is used to cut off the gap and grind it small. The guard shaft is used to reduce the deformation of the workpiece, prevent vibration, and cut off the reason for falling and bumping.

Conclusion

The above methods for processing thin-walled casing have solved the problem of deformation or causing size error and shape error which cannot meet the requirements. Practice has proved that the processing efficiency is high, it is easy to operate, and it is suitable for processing long thin-walled parts. The size is easy to master, and the batch production is also more practical.