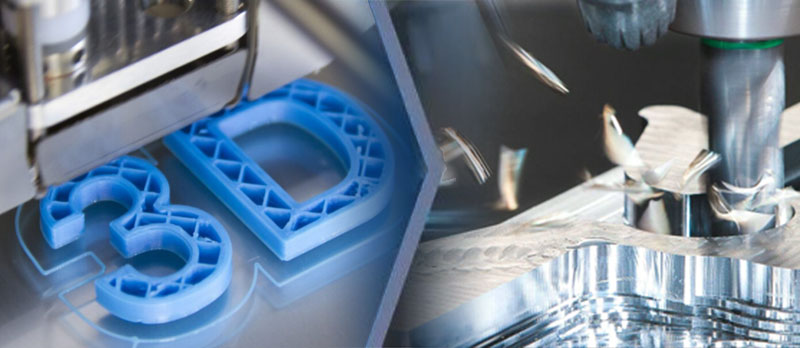

1. Differences In Materials

3D printing materials mainly include liquid resin (SLA), nylon powder (SLS), metal powder (SLM), gypsum powder (full color printing), sandstone powder (full color printing), wire (DFM), plate (LOM), etc. Liquid resins, nylon powders, and metal powders account for the vast majority of the industrial 3D printing market.

The materials used in CNC machining are sheets or bars. By measuring the length, width, height + wear of the part, the corresponding size of the plate is cut for processing. General hardware and plastic plates can be processed by CNC, and the density of molded parts is higher than that of 3D printing.

2. The Forming Principle Leads To The Difference Of Parts

3D printing is a kind of additive manufacturing. Its principle is to cut the model into N layers or N multi-points, and then pile them up bit by bit in order, just like building blocks. Therefore, 3D printing can effectively process parts with complex structures, such as hollow parts.

CNC machining is a type of subtractive manufacturing, in which various tools are operated at high speed to cut out the required parts according to the programmed tools. Therefore, CNC lathes can only process rounded corners with a certain radian, but cannot directly process right angles. This is achieved by wire cutting/EDM technology. It is no problem to use the outer right-angle CNC lathe, so the inner right-angle part can be considered for 3D printing.

If the surface area of the part is large, 3D printing is also recommended. Machining surfaces with CNC lathes is time-consuming, and if the master who programs and operates the machine is not experienced enough, it is impossible to leave a clear pattern on the part.

3. Differences In Operating Software

Most 3D printing slicing software is easy to operate, and even a layman can use the slicing software for a day or two under professional guidance. Because slicing software is easy to optimize and can automatically generate support, this is why 3D printing can reach individual users.

CNC programming software is much more complex and requires professional operation. People with zero foundation generally need to study for about half a year, and a CNC machine tool operator is also required to operate CNC machine tools.

Because the programming is very complicated, a part can have multiple CNC machining schemes, and 3D printing is relatively objective because only a small part of the processing time consumables are placed.

4. Differences In Post-Processing

There are not many options for 3D printing parts after processing, generally grinding, oil injection, deburring, dyeing, etc. In addition to grinding, oil injection, and deburring, the selection of CNC lathe processing parts also includes electroplating, silk screen printing, printing, metal oxidation, laser engraving, sandblasting and so on.

5. Different Practicability Of Products

3D printing products have the disadvantages of low strength and wear resistance. CNC machined products have the advantages of high strength and wear resistance.