Process planning refers to the entire process, and cannot be judged by the nature of a process and the processing of a certain surface. For example, some positioning reference planes need to be processed very accurately in the semi-finishing stage or even in the roughing stage. Sometimes in order to avoid dimensional chain conversion, in the finishing stage, semi-finishing of certain secondary surfaces can also be arranged.

After determining the processing method and processing stage of the part surface, the processing of each surface in the same processing stage can be combined into several steps.

Method Of Dividing Processing Procedures

The parts processed on CNC machine tools are generally divided into processes according to the principle of process concentration. The methods of division are as follows:

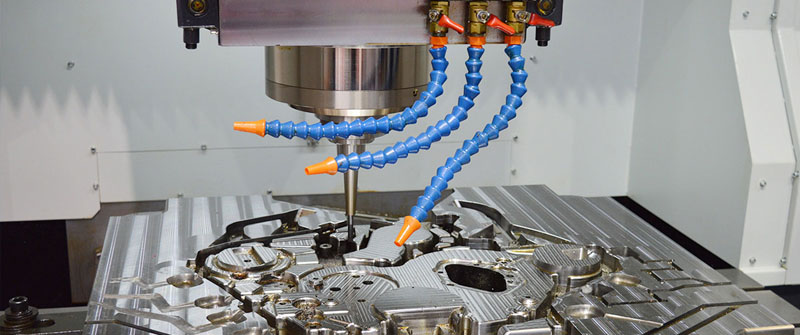

1) Divided according to the tools used

Taking the process completed by the same tool as a working procedure, this division method is suitable for situations where there are many workpiece surfaces to be machined. Machining centers often use this method to complete.

2) Divided by the number of workpiece installations

Take the technological process that can be completed in one clamping of the parts as a process. This method is suitable for parts with few processing contents. Under the premise of ensuring the processing quality of the parts, all processing contents can be completed in one clamping.

3) Divided by roughing and finishing

The part of the process completed in rough machining is regarded as one process, and the part of process completed in finishing is regarded as another process. This division method is suitable for parts that have strength and hardness requirements, require heat treatment or require high accuracy of parts, need to effectively remove internal stress, and have large deformation after machining, which needs to be divided into rough and fine machining stages.

4) According to the processing position, the part of the process that completes the same profile is regarded as a process.

For parts with many processing surfaces and more complex, the sequence of CNC machining, heat treatment and auxiliary procedures should be arranged reasonably, and the connection problem between the procedures should be solved. 2. The principle of the division of processing procedures Parts are composed of multiple surfaces, these surfaces have their own accuracy requirements, and there are corresponding accuracy requirements between each surface. .

Principles In The Processing Sequence

In order to meet the design accuracy requirements of the parts, the processing sequence arrangement should follow certain principles.

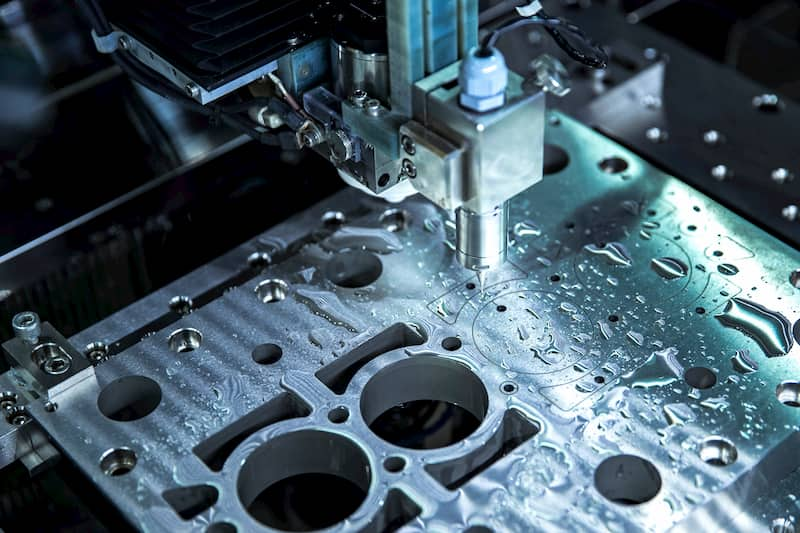

1) Rough first and then refined

The processing sequence of each surface is carried out in the order of roughing, semi-finishing, finishing and finishing, with the purpose of gradually improving the accuracy and surface quality of the processed surface of the part. If all surfaces of the part are processed by CNC machine tools, the process arrangement is generally carried out in the order of roughing, semi-finishing, and finishing, that is, semi-finishing and finishing are performed after all roughing is completed. During rough machining, most of the machining allowance can be quickly removed, and then each surface can be finished in turn, which can improve production efficiency and ensure the machining accuracy and surface roughness of the parts. This method is suitable for machined surfaces that require high position accuracy. This is not absolute. For example, for some machined surfaces that require high dimensional accuracy, considering the rigidity, deformation and dimensional accuracy of the parts, these machined surfaces can also be considered in the order of rough machining, semi-finishing, and finishing. carry out. For machining surfaces with high precision requirements, it is best to leave the parts for a period of time between roughing and finishing processes, so that the surface stress of the parts after roughing can be completely released, and the degree of stress and deformation on the surface of the parts can be reduced, which is beneficial to improve The machining accuracy of the parts.

2) Processing datum plane first

At the beginning of processing, the surface used as the finishing reference is always processed. Because the surface of the positioning reference is accurate, the clamping error is small. Therefore, in the processing of any part, the positioning reference surface is always roughed and semi-finished. Machining, finishing if necessary, for example, shaft parts are always rough and semi-finished on the positioning reference surface, and then finished. For example, shaft parts always machine the center hole first, and then machine the hole system and other surfaces based on the center hole surface and the positioning hole as a precision reference. If there is more than one precision datum surface, the processing of the datum surface should be arranged in accordance with the order of datum conversion and the principle of gradually improving the processing accuracy.

3) Face first, hole second

For box, bracket, machine body and other parts, the plane outline size is larger, and the plane positioning is more stable and reliable, so the plane should be processed first, and then the hole should be processed. In this way, not only the subsequent processing has a stable and reliable plane as the positioning reference surface, but also the processing of holes on a flat surface makes the processing easier, and it is also conducive to improving the processing accuracy of the holes. Generally, the processes can be divided according to the processing positions of the parts. Generally, simple geometric shapes are processed first, and then complex geometric shapes; the lower precision parts are processed first, and then the higher precision parts are processed; the plane is processed first, and the hole is processed later.

4) First inside and then outside

For precision sleeves, the coaxiality between the outer circle and the hole is required. Generally, the principle of hole first, outer circle is adopted, that is, the outer circle is used as the positioning reference to machine the hole, and then the hole with higher precision is used as the positioning reference to process the outer circle. Round, which can ensure a high coaxiality requirement between the outer circle and the hole, and the fixture structure used is also very simple.

5) Reducing the number of tool changes

In CNC machining, the machining sequence should be arranged in the order in which the tool enters the machining position as much as possible.