Polyoxymethylene (POM), also known as acetaldehyde, polyoxymethylene, or polyoxymethylene, is one of the plastic materials with many advantages in CNC machining parts. This type of plastic is widely popular in multiple industries due to its excellent properties, advantages, and various uses. Due to its chemical resistance, dimensional stability, mechanical strength, and low friction, it is a reliable material in engineering applications.

The Properties Of POM

High performance engineering plastic polyoxymethylene (POM) is widely used in many fields. It is suitable for various applications due to its unique properties.

Low Friction And Wear Resistance:

POMs stand out for their low friction coefficient, which helps explain why they have such excellent self-lubricating performance. Due to the reduction of frictional resistance and wear, the overall efficiency is higher, and fluid sliding or rotational motion can be achieved.

Chemical Resistance:

POM is very suitable for manufacturing products that come into contact with chemical solvents and other substances, such as pump parts, seals, and fuel system components. This is mainly attributed to the excellent resistance of POMs to various chemicals, solvents, and fuels. It can resist contact with many organic chemicals, alcohols, oils, and lubricants without significant deterioration.

Low Water Absorption And Dimensional Stability:

POMs have excellent dimensional stability, maintaining their size and shape even under conditions of humidity and temperature changes. Due to its low water absorption, it is not easily affected by moisture, warping, and other size changes related to moisture. Applications that require precise tolerances and consistency performance also heavily rely on the dimensional stability of POM.

Workability:

The ease of processing of POMs enables precise and efficient manufacturing processes. It is easy to shape, process, turn, and drill, making it easy to manufacture complex parts and designs. Because of this characteristic, POM resins are commonly used in applications that require complex geometric shapes and high precision.

Excellent Impact Resistance:

POMs exhibit excellent creep resistance, which means they can withstand continuous mechanical stress without deformation. Due to this characteristic, POM parts can still function normally even under continuous load or strain.

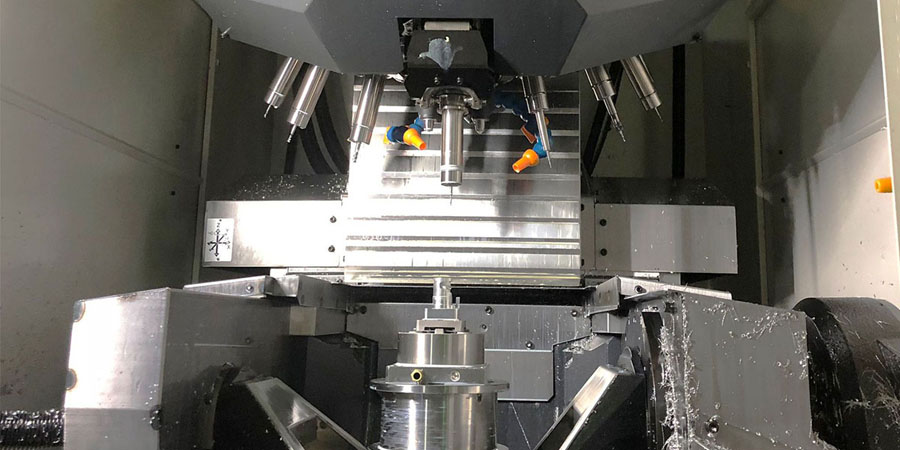

How To Process POM With CNC?

POM CNC machining refers to the use of CNC machines to cut POM (polyoxymethylene) plastics. This processing method can achieve high-precision and high-efficiency processing, as well as complex geometric shapes and structures.

When conducting POM CNC machining, it is necessary to first determine the machining plan and process flow. Usually, CNC processing of POMs requires the following steps:

1. Material Preparation:

Prepare the POM materials that need to be processed and perform necessary cleaning and treatment.

2. CNC Programming:

According to the shape and structure that needs to be processed, write a CNC program to determine parameters such as cutting path, cutting speed, and feed rate.

3. Clamp Positioning:

Fix the POM material on the workbench of the CNC machine tool to ensure that the material does not move during the processing.

4. Cutting:

Cutting is carried out according to the CNC program, controlling the cutting speed, feed rate and other parameters of the machine tool to ensure machining quality and efficiency.

5. Testing And Quality Control:

Inspect the processed POM parts to ensure compliance with design requirements and quality standards.

Precautions For POM CNC Machining:

-

Tool Selection:

Select the appropriate tool for cutting according to the shape and structure that needs to be processed.

-

Cutting Parameter Control:

Control cutting speed, feed rate and other parameters to avoid problems such as high cutting temperature and excessive cutting force.

-

Material Treatment:

POM has hygroscopicity, so it needs to be dried before processing to avoid the impact of water vapor on processing quality.

-

Precision Control:

In CNC programming, precision control needs to be considered to ensure that the processed parts meet design requirements and quality standards.

-

Safe Operation:

When performing CNC machining, it is necessary to pay attention to safety operating procedures to avoid accidents.

In summary, POM is an excellent plastic material used for CNC machining to make mechanical components and industrial products. Although POM is easy to machine, it is prone to deform during processing. However, by utilizing the recommended machining processes, including adequate cooling, reducing tool eating, and ensuring sharp tools, it is possible to minimize such deformations and other associated problems.