The more and more widespread application of aluminum alloy parts puts forward higher requirements on machining technology, and the aluminum alloy precision parts machining industry has entered a new period of rapid development. It has been widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, chemical industry and daily life. It is very strong, making it an ideal material for mechanical parts, and its oxidized outer layer can resist elemental corrosion. These advantages make aluminum parts common in all industries. In this article, we will discuss the advantages of CNC machining aluminum parts and their applications in the electronics industry.

CNC Aluminum Machining Advantages

1. Easy To Process

One of the main reasons why engineers choose CNC aluminum machining parts is because it is very simple and the material is easy to process. Although this seems to be more beneficial to the mechanic who makes the part, it also has significant benefits to the company that ordered the part and the end user who ultimately uses it.

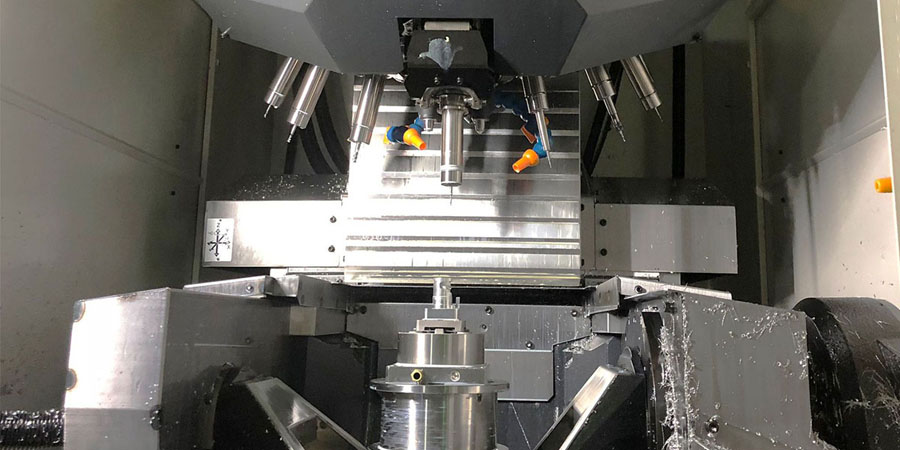

Because aluminum is easy to chip, and because it is easy to shape, it can be cut quickly and accurately with CNC machine tools. This has some important consequences: First, short-term machining work makes the process cheaper (because less labor requires a machinist and less operating time requires the machine itself). Secondly, good cutting performance means that when the tool passes through the workpiece, the deformation of the workpiece is small. This allows the machine to meet tighter tolerances (as low as ±0.025 mm), resulting in higher accuracy and repeatability.

2. Corrosion Resistance

Different grades of aluminum differ greatly in terms of corrosion resistance, oxidation resistance and chemical damage. Fortunately, some of the most popular CNC aluminum machined parts grades are the most wear-resistant.

3. Strength To Weight Ratio

Aluminum has ideal physical properties, making it an ideal material for machinery and external parts. The two most important points are the high strength and light weight of this metal. These two factors make this material useful for manufacturing critical components, such as those required by the aerospace and automotive industries.

However, different grades of aluminum have different uses. Due to its good strength-to-weight ratio, general-purpose grades such as 6061 can be used for various components, while high-strength grades such as 7075 may be more suitable for aerospace and marine applications.

4. Conductivity

CNC aluminum machined parts can be used for electrical components due to their electrical conductivity. Although the conductivity is not as good as copper, the conductivity of pure aluminum at room temperature is about 37.7 million siemens/meter. The conductivity of the alloy may be low, but the conductivity of aluminum is significantly higher than that of stainless steel and other materials.

5. Anodizing Potential

CNC aluminum machining parts are particularly popular in the consumer electronics industry, not only because of the strength and weight requirements, but also because of important aesthetic considerations. In addition to being easy to accept paint and coloring, aluminum can also be anodized, which is a surface treatment process that can thicken the protective and oxidized outer layer of the part.

The anodizing process is usually carried out after the mechanical processing is completed, including passing current in an electrolytic acid bath to obtain aluminum sheets that are more resistant to physical shock and corrosion.

Importantly, anodizing makes it easier to add color to mechanical aluminum parts because the anodized outer layer is highly porous. Dyes can pass through the porous part of the outer layer, and because they are embedded on the outside of the hard metal part, they are unlikely to crack or peel off.

6. Recyclability

Another benefit of CNC aluminum machining parts is its high recyclability, which makes it more suitable for companies seeking to minimize their environmental impact, or companies that just want to reduce material waste and recover some of the costs. Recyclable materials are particularly important in CNC machining, because in CNC machining, the chips on the tool will produce relatively large waste.

Why CNC Aluminum Parts Machining Is Popular In The Electronics Industry

Based on the process exploration of “appearance” and “performance”, smart phone shells, smart TV frames, smart wearable devices such as smart watches and other surfaces, tablet computers, etc. can all use high-quality aluminum alloy materials to make products lighter, more environmentally friendly, practical, and Beautiful. Because aluminum alloy materials have the strength of metal, are light in weight, easy to dissipate heat, and have strong compression resistance. With the development of consumer electronics products, consumer electronics companies pay more and more attention to product design and material technology. , In order to enhance the brand image and user experience, so that the application potential of aluminum in the electronics industry is continuously tapped. Aluminum alloys are mainly embodied in the form of shells, frames, radiators and aluminum tubes in consumer electronic products.

PCB Consumer Electronics

Apple MacBook and its various models (MacBook Pro, MacBook Air) are one of the most well-known consumer electronic products in the world. Its sturdy and durable aluminum body is made with CNC milling technology.

Although die casting is a widely used process for making these enclosures, CNC machining is quickly becoming a more reliable and preferred method. Compared with die casting and injection molding, they can produce more complex geometries, achieve tighter tolerances, and provide higher strength.

Apple relies heavily on CNC machining processes to manufacture one-piece shells for iPhone, iPad and MacBook. The MacBook case is carved out of an extruded aluminum block using a CNC machine. The keyboard hole and the “thumb spoon” (the round groove that allows you to open the display cover) are also made using a CNC milling machine.

Heat Sink

A radiator is a widely used electronic device that transfers heat from electronic components to liquid coolant or air. Radiators are used in computers and other equipment to cool key components to maintain normal functions.

Machinable metals such as aluminum or copper are used, and the radiator can be manufactured using CNC machining technology. Precision CNC machines can even manufacture very small radiators, and can create equipment in various configurations according to requirements.

Conclusion

Aluminum processing is widely used in consumer electronic products, from mobile phones, earphones, speakers, watches, to TVs, laptops and even various smart homes. With the continuous growth of the economy, the global demand for electronic communications and other products will also continue to grow, which will also promote the expansion of the application of aluminum in various sub-fields, and gradually develop in the direction of high-end and specialization. Innovate and upgrade aluminum processing technology, pay attention to new trends and applications of aluminum materials, develop high-precision products, and open up new markets to expand the overall demand for aluminum for consumer electronics.