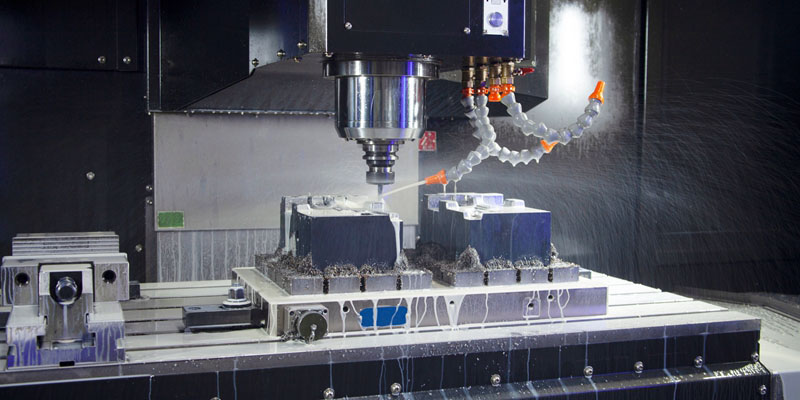

Prototyping is the heartbeat of product development, and in the realm of precision and speed, CNC machining stands as a champion. The marriage of CNC machining and prototyping brings forth a dynamic duo, offering rapid iteration and robust design validation. In this post, we’ll delve into the symbiotic relationship between CNC machining and prototyping, exploring how this combination accelerates the product development lifecycle.

Rapid Iteration Through CNC Machining:

Swift Design Modifications:

CNC machining excels in producing prototypes with unparalleled speed. This agility allows designers and engineers to swiftly implement design modifications based on real-world testing and feedback.

Reduced Time-to-Market:

The iterative nature of prototyping often involves multiple design cycles. CNC machining’s ability to quickly materialize design changes significantly reduces the time-to-market for new products.

Complex Geometries with Ease:

CNC machining can effortlessly handle complex geometries and intricate designs. This capability is crucial during the prototyping phase when designers may experiment with diverse shapes and configurations.

Material Flexibility:

CNC machines can work with a wide array of materials, including metals, plastics, and composites. This flexibility allows designers to choose materials that closely mimic the intended end-product, providing a more accurate representation during prototyping.

Design Validation with CNC Machining:

Precision and Accuracy:

CNC machining ensures high precision and accuracy, critical for validating design specifications. The prototypes produced reflect the exact dimensions and tolerances specified in the design.

Material Performance Testing:

Prototypes from CNC machining undergo real-world material performance testing. This includes assessing how the material responds to stress, heat, and other environmental factors, providing invaluable insights for material selection in the final product.

Functional Prototypes:

CNC machining allows for the creation of functional prototypes that closely emulate the intended product’s behavior. This is especially beneficial for validating mechanical components and ensuring that the prototype functions as expected.

Iterative Testing and Feedback:

CNC-machined prototypes enable iterative testing. Designers can receive rapid feedback, identify areas for improvement, and implement changes iteratively, ensuring the final design is robust and reliable.

Cost-Effective Validation:

CNC machining offers a cost-effective means of validating designs. Compared to traditional tooling and molding processes, CNC prototyping requires minimal setup costs, making it an economical choice for design validation.

The CNC Machining Advantage:

Unmatched Speed:

CNC machining, with its automated and computer-controlled processes, provides unmatched speed in turning digital designs into tangible prototypes. This speed is instrumental in keeping pace with the demands of rapidly evolving markets.

High-Quality Finishes:

CNC-machined prototypes boast high-quality surface finishes, allowing for a visual and tactile assessment of the design. This is crucial for evaluating the aesthetic aspects of a product.

Scalability:

Prototypes developed through CNC machining can serve as a foundation for scalable production processes. Once a design is validated, the transition to larger-scale production becomes more seamless.

In conclusion, the synergy between CNC machining and prototyping is transformative for product development. The rapid iteration facilitated by CNC machining accelerates the design process, while the precision and versatility contribute to robust design validation. This dynamic interplay not only reduces time and costs but also enhances the overall quality of the end product. As industries continue to push the boundaries of innovation, the marriage of CNC machining and prototyping will remain a cornerstone of agile and efficient product development.