Metal prototypes are important for companies in many industries, from aerospace to electronics, because effective metal prototypes can lead to better finished products. Metal prototypes are prototypes made using metal manufacturing techniques such as CNC machining, casting or sheet metal forming. They can be made of aluminum, steel or any other material chosen by the engineering team. Among them, the aluminum manufacturing technology is numerous and complete. Fortunately, it is easy to find well-known aluminum machining services nowadays, which will bring your prototype to life. There are several reasons why aluminum fabrication was chosen as the method of manufacturing prototypes.

Excellent Processability

The factor of machinability is the efficiency of machining metal. Aluminum has an excellent workability score. The calculation method is the current material processing speed divided by the sample material processing speed. The sample is usually some simple carbon steel. Now, if we compare the processing speed of aluminum alloy with the processing speed of 1212 steel, we will get 360% cutting force, which means that the cutting speed of aluminum is 3.6 times that of steel. Of course, steel may be stronger and more durable, but processing time is more important for making prototypes. You only need to sacrifice a little durability to get prototypes faster through aluminum machining.

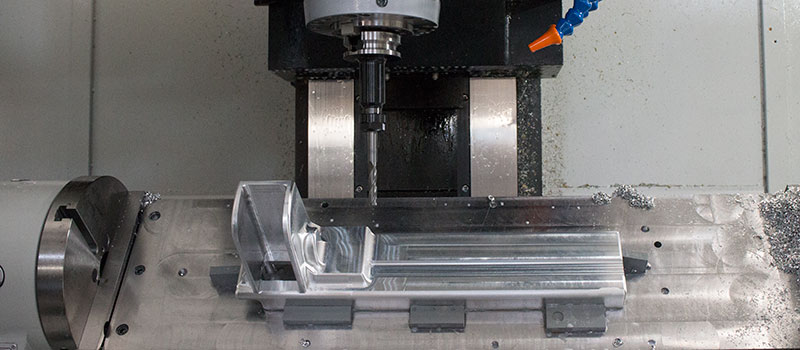

Aluminum alloys can be processed by a variety of techniques. Because they are conductive, they also offer some electrochemical and coating options. Among the most popular methods, aluminum processing companies use CNC turning, CNC milling, grinding, polishing, honing, drilling and tapping, electrical discharge machining (EDM), electrochemical machining, slotting, etc. By combining various techniques, you can obtain almost any part of complexity and precision.

Extremely High Precision And Surface Finish

Custom aluminum manufacturing is based on CNC machining, which we call CNC aluminum. Unlike other processes, it does not involve melting and continuous solidification, and all heat treatments have inevitable deformation. CNC machining is the process of producing the best surface finish and tolerances. If you add some polishing operations, you can even get a mirror-like surface. The maximum achievable tolerance in aluminum processing is IT8-7, and the surface finish is RA 1.25 µm.

Corrosion Resistance

Aluminum has the unique advantage of corrosion resistance. If corrosion is the key factor for your order, just choose metallic aluminum as your material of choice. The resistance comes from a thin oxide layer formed on the exposed surface of aluminum, which is only a part of a millimeter thick. Its function is to protect the metal from any external harmful substances. Therefore, your parts do not require additional paint or coating, which can avoid rust.

Strong Weight-To-Strength Ratio

Aluminum alloy is 3 times lighter than steel. This is why they are often used in the aerospace industry. Although they are very lightweight, many alloys have been modified to match the strength of aluminum and steel. Therefore, if you are considering the production of certain products whose weight is a key parameter, such as handheld devices or airplanes. You should not only consider choosing an aluminum alloy for the prototype, but also an aluminum alloy for the final part.

Non-magnetic Alloy

Aluminum does not react with magnets. This is a crucial factor, especially when you are looking for parts that are resistant to magnetic fields. Although there are other alloys with similar properties, aluminum is a cheaper and more stringent choice. Therefore, it is a good and reasonably priced choice for equipment housings that do not require magnetization.

Medical Use

This is not a well-known fact, but certain aluminum alloys can be used in the medical industry. For example, 6063, 6061 and 3003 alloys are completely compatible with human tissues. When biocompatible metal parts are considered and aluminum alloys are an affordable option, medical manufacturers have a limited number of options. If we look at another option, it is titanium. Titanium alloy has excellent machinability, while aluminum is both efficient and easy to manufacture.

High Conductivity

Copper is usually ideal for electrical parts and wiring. Although copper has excellent electrical conductivity, it is soft, expensive, and has poor corrosion resistance. However, in addition to having almost the same electrical conductivity as copper, aluminum can also offset all these negative characteristics. Therefore, you can use aluminum processing for prototyping electrical equipment, especially when you want to manufacture some complex electrodes.

Easy To Recycle

Modern industry sees itself as an eco-friendly and sustainable developer and minimizes air pollution. Over the years, this factor has become more and more important in the selection of product materials. This is why polymers and plastics are no longer used by default. After all, when the product meets its due requirements, removing plastic parts can be troublesome. Generally, recycling industrial-grade plastics is a complex and expensive process. Merely burning them or keeping them in the dump is not the best option. Therefore, manufacturers want other materials to become more environmentally friendly.

Aluminum alloy definitely meets environmental protection requirements. You can recycle them completely. They can be smelted and used in the next part with almost no waste. In addition, you can pay for some aluminum manufacturing costs by selling chips obtained from prototype manufacturing or small batch production.

Conclusion

There are dozens or more reasons why aluminum is so popular and why everyone is in love with aluminum fabrication. Aluminum fabrication is an excellent choice to meet the needs of prototyping. Contact SANS Machining now to get the aluminum prototype.

Thank you for your advice about getting an aluminum alloy for both the prototype and the final part. I was told that it is only good for the prototype. However, after reading your article, you made sense of why I should get it for both.