Surface finishing in manufacturing enhance the functionality and aesthetics of products and enhance other properties suitable for protecting products from corrosion, wear and more. What is Alodine®? Alodine®, also known as chemical film or chemical film, is a chromate conversion coating that protects aluminum and other metals from corrosion. The process of applying a chromate conversion coating is called chromating.

Here, we will introduce you about the Alodine finish of aluminum parts, including the definition of Alodine, common types, the difference from anodizing, and application areas.

What Is Alodine?

Alodine is a chemical that dissolves in an aqueous solution to create a gel for metals such as aluminum alloys. It forms a coating that protects the metal and enhances its aesthetic appeal. However, the name “Alodine” is registered as a trademark by Henkel Surface Technology. The common name for this chemical film is “chromate conversion coating”.

A chromate conversion coating is a chemical conversion coating. In chemical conversion coatings, metals undergo chemical reactions on the surface. This chemical reaction converts the metal surface into a protective layer.

While providing aluminum corrosion protection, chemical films or Alodine coatings also provide the basis for the surface finish of organic coatings, which prevent loss of electrical conductivity.

The chemical film is applied by dipping, brushing or spraying, and the thickness of the chromate conversion coating does not change the size of the part. A conversion coating on aluminum can also improve paint and primer adhesion if it is applied to the aluminum surface before primer.

Chromate Conversion Coating Types

Different types of chromate conversion coatings generally differ in chemical composition and shape. While there are many different types, the most typical are Type 1 and Type 2 of the MIL-DTL-5541 standard. Other standards currently available are AMS-C-5541, MIL-C-81706, and AMS-2473 and 2474.

Of the five above, the two most typical in manufacturing are:

MIL-DTL-5541 Standard (Type I)

The Class 1 MIL-DTL-5541 standard contains hexavalent chromium, which produces brown or gold films and sometimes even clear films. Also known as hexavalent chromium due to the presence of hexavalent chromium, it was traditional alotene for many years before Type 2 and other safer chemicals came along.

Hexavalent chromium is a hazardous chemical that is labeled as a carcinogen by OSHA. Therefore, some countries do not allow it to be used. Those permitted for use require processing permits, proper ventilation and disposal methods.

Such films are usually brown or gold in color, but may also be colorless, in which case they are “clear”.

MIL-DTL-5541 Standard (Type II)

MIL-DTL-5541 Type 2 is the world’s standard alodine. Unlike Type 1, it contains trivalent chromium, titanium or zirconium. Therefore, it is called hexagonal-free chrome. The coat is usually colorless and therefore described as transparent.

The Type 2 standard replaced Type 1 as the most widely used chromate conversion coating standard shortly after the advent of the alodine finish.

Some particularly desirable properties of Type 2 compared to Type 1 include:

- Better safety makes it more favored by the precision machined parts manufacturing industry

- Alodine aluminum coating application temperature is lower than Type 1

- Simpler, faster and more direct application process

Alodine Vs. Anodizing: What’s The Difference

Both alodine and anodizing are conversion coating processes and are sometimes confused with each other due to the similar production processes. They involve dipping parts in chemicals and forming a coating. However, the two surface finishes are different. Below are some of the differences between the two processes.

Process

The difference between alodine and anodizing becomes clearer by understanding the process itself. Anodizing is an electrolytic process that involves coating a metal with its oxide. For example, anodized aluminum makes parts more resistant to corrosion and wear. This is different from chromate conversion coating, which is a simple chemical process that does not use electrical current.

Influences

The alodine finish has very little effect on the size of metal parts, with thicknesses ranging from 0.00001 to 0.00004 inches. This is different from anodizing which forms a thicker layer (ranging from 0.00001 in Type 1 anodizing to 0.001 in Type III anodizing.)

Purpose

Both conversion coating methods are suitable for achieving corrosion resistance. However, anodizing has better aesthetic appeal. Therefore, it is more suitable for decorative purposes.

Cost

Alodine finishes cost less than anodizing. However, you should consider the different types of alodine, the size of the metal, and other effects as they can also affect the price.

Application Of Alodine Finish

Alodine finishing is widely used in many industries of manufacturing. Below are some applications of finish options.

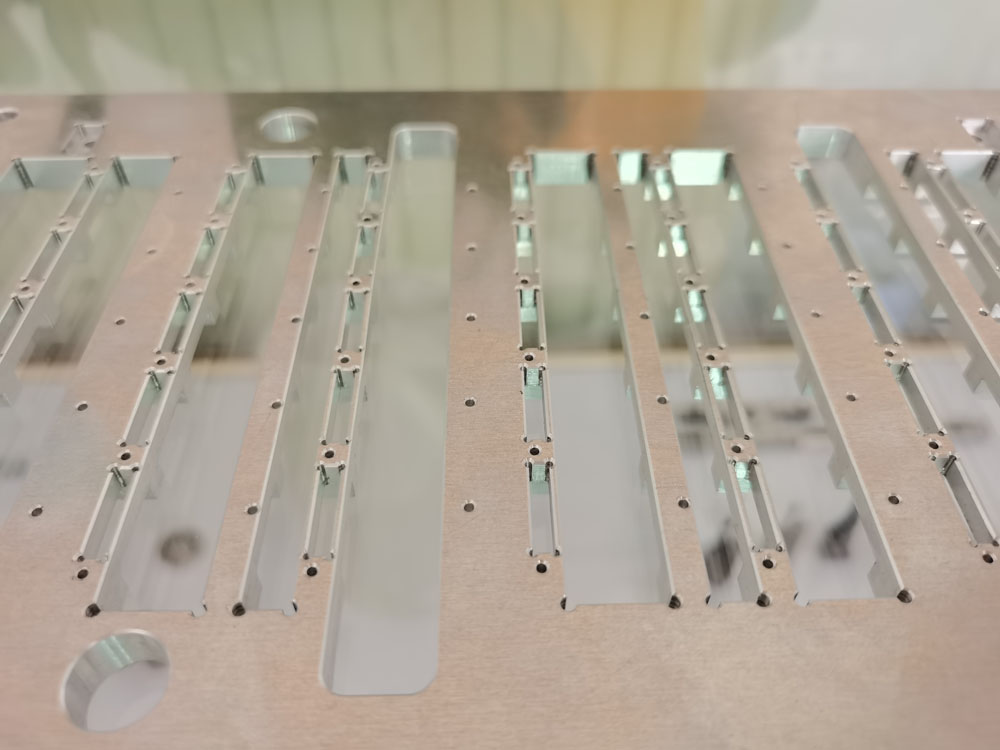

CNC Precision Machining Parts

One of the most common alodine coating applications is the surface treatment of CNC precision machined parts. CNC-manufactured metal parts are protected from corrosion and surface action contaminants by an aluminate coating. What makes alodine ideal is that the final dimensions of the metal parts do not change significantly. Other benefits of CNC machined parts are improved adhesion during priming and changing the conductivity of the coating.

These, combined with the fact that the entire process is simple and straightforward, make Alodine aluminum finishes indispensable in precision machined parts.

Aviation Industry

Many parts in the aerospace industry contain aluminum, probably because of its light weight and robustness. Therefore, alodine coating is crucial as a surface treatment for these parts. Some of these parts are aircraft fuselage, landing gear, shock absorbers, etc.

Military And Defense Industry

Parts used to manufacture military and defense industrial products must resist corrosion. For example, ship interiors and other mechanical components in the Navy are often infiltrated by salt water, making them susceptible to corrosion. Therefore, the alodine coating can protect aluminum and other important materials.

Conclusion

Alodine coating is an aluminum metal finish that helps protect the metal from corrosion. Since the use of aluminium in industrial parts is so common these days, basic knowledge of alodine is a must, especially when dealing with precision parts.