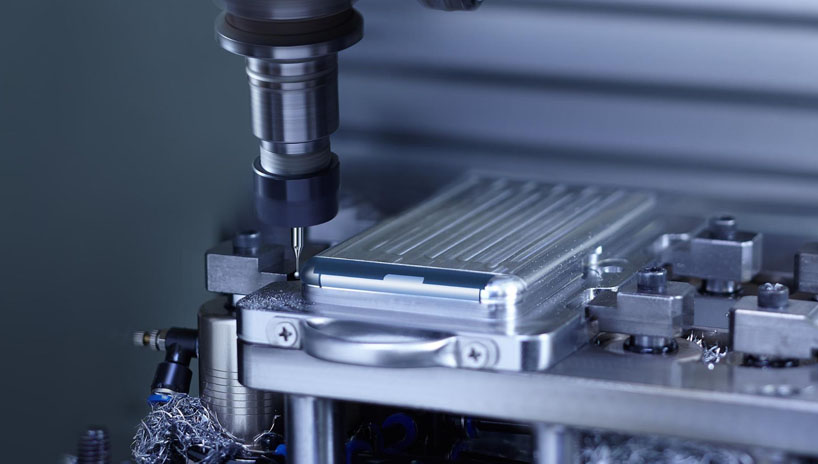

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining has revolutionized the way industries produce intricate parts and components. CNC machining offers a multitude of advantages that have significantly improved manufacturing processes across various sectors. From enhanced precision to increased efficiency, CNC machining has become a cornerstone technology in the pursuit of high-quality, cost-effective, and innovative manufacturing solutions. In this article, we will explore the key advantages of CNC machining and its impact on the manufacturing industry.

1. Precision and Accuracy:

One of the most significant advantages of CNC machining is its ability to achieve unparalleled precision and accuracy. CNC machines are driven by computer programs, which enable precise control of cutting tools and movements. This results in consistent and repeatable machining processes, ensuring that each part is manufactured to exact specifications. With CNC machining, manufacturers can achieve tight tolerances and produce complex geometries that were once challenging to accomplish using traditional machining methods.

2. Increased Efficiency and Productivity:

CNC machining significantly boosts manufacturing efficiency and productivity. The automation and computerized control of CNC machines allow for continuous operation, 24/7, without the need for constant human intervention. Unlike conventional manual machining, CNC machines do not require operators to physically guide the cutting tools, which reduces idle time and non-cutting operations. This increased efficiency translates to higher production rates, shorter lead times, and reduced manufacturing costs.

3. Versatility and Flexibility:

CNC machining offers remarkable versatility, as it can work with various materials, including metals, plastics, composites, and more. It also accommodates a wide range of part sizes and complexities, making it suitable for both small-scale and large-scale production. Additionally, CNC machines can be easily reprogrammed to produce different parts, allowing for rapid changes in production runs and adaptability to evolving market demands.

4. Cost-Effectiveness:

Despite the initial investment in CNC equipment and programming, CNC machining ultimately proves cost-effective over time. Once programmed, CNC machines can produce parts consistently and accurately without the need for constant manual adjustments. This reduces labor costs and minimizes the risk of errors that could lead to costly rework or scrap. Additionally, the ability to optimize tool paths and material utilization reduces waste, further contributing to cost savings.

5. Complex Part Manufacturing:

CNC machining excels at manufacturing complex parts that are difficult or impossible to produce with conventional machining techniques. CNC machines can execute intricate tool paths and perform multi-axis movements, enabling the creation of complex geometries and contoured surfaces. This capability is particularly valuable in industries such as aerospace, automotive, and medical, where components often require intricate shapes and designs.

6. Consistent Quality and Reproducibility:

With CNC machining, manufacturers can achieve consistent quality and reproducibility in every part they produce. The digital nature of CNC programming ensures that the same machining parameters are applied to each part, eliminating variations caused by human error. This consistency is essential in industries that demand strict adherence to quality standards and regulatory requirements.

7. Rapid Prototyping and Design Iterations:

CNC machining allows for rapid prototyping and design iterations. Manufacturers can quickly produce functional prototypes using CNC machines to test and validate their designs before committing to full-scale production. This iterative process enables engineers and designers to identify and address design flaws, optimize part performance, and reduce time-to-market.

In conclusion, CNC machining offers a plethora of advantages that have revolutionized manufacturing processes. From its exceptional precision and increased efficiency to its versatility and cost-effectiveness, CNC machining has become an indispensable technology in modern industry. Its ability to manufacture complex parts consistently and reproduce intricate geometries has propelled industries to new heights of innovation and productivity. As technology continues to advance, CNC machining will undoubtedly remain a driving force in manufacturing, empowering companies to meet the challenges of a dynamic and competitive global market.