Wire Electrical Discharge Machining (Wire EDM) is widely recognized for its ability to produce complex geometries, sharp internal corners, and high-precision features that are difficult or impossible to achieve with conventional machining. However, successful Wire EDM processing depends on more than machine capability or programming accuracy. One of the most critical—and often underestimated—factors is material compatibility.

Understanding how different materials respond to the Wire EDM process directly affects cutting stability, surface quality, dimensional accuracy, and overall production efficiency.

Understanding the Fundamentals of Wire EDM

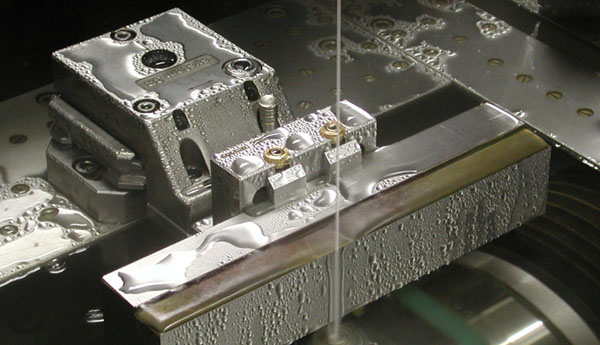

Wire EDM is a non-contact machining process that removes material through controlled electrical discharges between a continuously fed wire electrode and a conductive workpiece. Material removal occurs through localized melting and vaporization, rather than mechanical cutting forces.

Because there is no direct tool pressure, Wire EDM is ideal for machining delicate features, hardened materials, and complex profiles. However, the process relies entirely on electrical conductivity and controlled spark behavior. This makes material properties a determining factor in machining performance.

Why Material Compatibility Matters in Wire EDM

Not all conductive materials behave the same way during Wire EDM. Differences in electrical conductivity, thermal conductivity, melting temperature, and microstructure influence how efficiently material is removed and how stable the cutting process remains.

Material compatibility affects several key outcomes:

- Cutting speed and productivity

- Surface finish and recast layer quality

- Dimensional accuracy and edge integrity

- Wire wear and breakage risk

- Overall process stability

Ignoring material-specific behavior often leads to inconsistent results, excessive secondary finishing, or unnecessary process adjustments.

Electrical Conductivity and Spark Stability

Electrical conductivity is one of the most important material properties in Wire EDM. Materials with higher conductivity allow more consistent spark generation, resulting in smoother cutting behavior and better surface quality.

Low-conductivity materials tend to produce unstable discharge conditions. This can lead to irregular erosion, slower cutting speeds, and increased risk of wire breakage. Adjustments to pulse parameters may compensate to some extent, but productivity and surface consistency are often affected.

Selecting appropriate cutting parameters based on material conductivity is essential to maintaining stable erosion and predictable results.

Thermal Properties and Heat Dissipation

Thermal conductivity and melting temperature play a significant role in how materials respond to electrical discharge energy. Materials that dissipate heat efficiently tend to form cleaner cut surfaces with thinner recast layers.

Conversely, materials with poor thermal conductivity may experience localized overheating. This can increase surface roughness, deepen the heat-affected zone, and raise the likelihood of micro-cracking—especially in precision or fatigue-sensitive components.

Understanding how a material handles heat allows machinists to balance cutting speed and surface integrity more effectively.

Common Materials and Their Wire EDM Behavior

Tool steels and hardened steels are among the most common materials machined using Wire EDM. Their consistent conductivity and stable microstructure make them well suited for precision cutting, even at high hardness levels. Wire EDM allows these materials to be machined after heat treatment without introducing mechanical stress.

Stainless steels generally perform well, though variations in alloy composition can affect cutting speed and surface finish. Parameter optimization is often required to maintain consistent results across different grades.

Carbides present unique challenges. While they are conductive, their brittle structure and high melting temperature require careful control to avoid surface cracking and excessive wire wear. Multiple skim cuts are commonly used to achieve acceptable surface quality.

Titanium alloys are conductive but exhibit lower thermal conductivity. This often results in slower cutting speeds and requires precise energy control to minimize surface damage and recast layer thickness.

Aluminum alloys, although conductive, can behave unpredictably due to rapid heat dissipation and material melting characteristics. Special attention is needed to prevent wire breakage and maintain dimensional stability.

Material Microstructure and Internal Stress

Material microstructure also influences Wire EDM outcomes. Fine, uniform grain structures typically respond more consistently to electrical discharge erosion. In contrast, materials with heterogeneous microstructures may erode unevenly, leading to surface irregularities or dimensional variation.

Residual internal stress within the material can further complicate results. During Wire EDM, localized heating may release internal stress, causing slight part movement or distortion—particularly in thin or long features. Understanding the material’s stress condition helps determine appropriate cutting strategies and fixture design.

Wire Selection and Material Interaction

Wire material selection should be aligned with the workpiece material. Brass, coated brass, and zinc-coated wires each interact differently with various materials in terms of cutting speed, spark stability, and surface finish.

Matching wire characteristics to material behavior improves energy transfer efficiency and reduces wire consumption. This is especially important when machining challenging materials or tight-tolerance components.

Process Optimization Based on Material Properties

Successful Wire EDM machining is rarely achieved with universal settings. Each material requires tailored parameters, including pulse duration, peak current, wire tension, and flushing conditions.

Material compatibility determines how aggressive or conservative these settings can be. Well-matched parameters improve cutting stability, reduce secondary finishing, and extend consumable life. Poor compatibility, even on advanced machines, leads to inconsistent results and increased production cost.

Quality Considerations for Precision Applications

In industries such as aerospace, medical, and tooling, Wire EDM parts often serve critical functional roles. Surface integrity, recast layer thickness, and dimensional accuracy directly influence part performance and service life.

Material compatibility determines whether a component can meet these requirements without extensive post-processing. Understanding material behavior early in the process helps engineers and machinists design realistic tolerances and select appropriate finishing strategies.

Conclusion

Wire EDM success depends on far more than machine accuracy or programming expertise. Material compatibility is a foundational factor that influences cutting behavior, surface quality, dimensional stability, and overall process efficiency.

By understanding how different materials interact with electrical discharge energy—and by adjusting parameters, wire selection, and cutting strategies accordingly—manufacturers can unlock the full potential of Wire EDM technology. In precision machining, aligning the process with material behavior is often the difference between acceptable results and truly reliable performance.