The robotics industry has rapidly transformed in recent years, driven by automation, artificial intelligence, and the growing demand for smarter, more efficient machines. Behind the sleek designs and advanced capabilities of modern robots lies a critical foundation: high-precision components. Producing these parts requires a manufacturing method that can deliver accuracy, repeatability, and reliability at scale. This is where CNC machining has established itself as the gold standard for robotic parts manufacturing.

The Demands of Robotic Component Manufacturing

Robots, whether used in industrial automation, healthcare, aerospace, or consumer applications, require parts that meet exceptionally tight tolerances. Even the slightest dimensional error in a gear, housing, or joint can lead to misalignment, loss of efficiency, or complete system failure. In addition, robotic parts must often balance lightweight design with high strength, incorporate complex geometries, and resist wear in demanding environments.

These requirements place enormous pressure on manufacturers to adopt processes that not only achieve the necessary precision but also support design flexibility, scalability, and durability.

Why CNC Machining Stands Out

1. Unmatched Precision and Tolerances

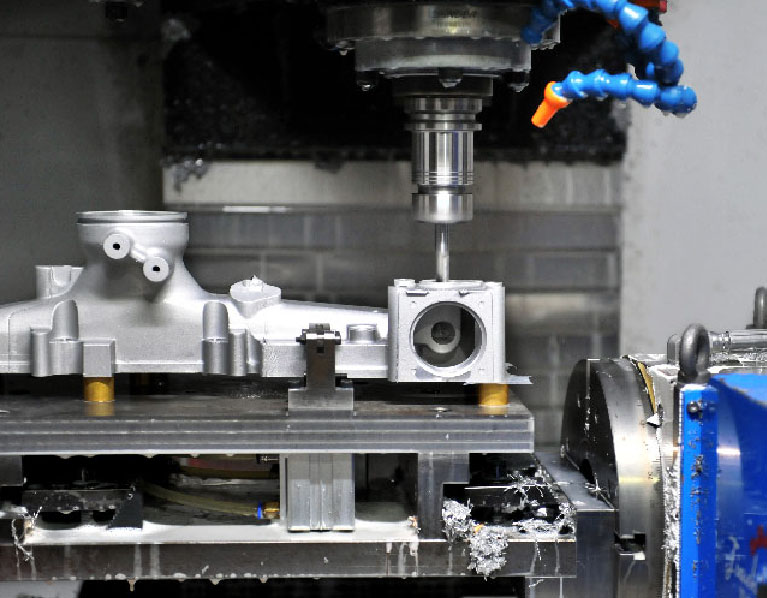

CNC machining consistently achieves tolerances in the micrometer range, a level of accuracy essential for robotic components like actuators, gear systems, and end effectors. Unlike casting or additive processes, CNC machining can maintain uniformity across high-volume runs, ensuring every part integrates seamlessly into robotic assemblies.

2. Superior Material Versatility

Robotic components are manufactured from a wide range of materials—aluminum for lightweight arms, stainless steel for structural strength, titanium for aerospace-grade robots, and engineering plastics for insulating or wear-resistant applications. CNC machining handles this material diversity with ease, allowing engineers to select the best option for performance without being limited by the manufacturing method.

3. Design Flexibility and Complexity

Modern robots often feature complex geometries, such as multi-axis joints, custom brackets, and housings with intricate internal features. CNC machines, especially multi-axis systems, can produce these components with high consistency. Engineers can directly translate CAD designs into machined parts, supporting innovation without excessive tooling modifications.

4. Repeatability for Scaled Production

Robotics companies need consistency. A robot built for industrial automation may require hundreds of identical components. CNC machining ensures that once the first part is perfected, every subsequent piece can be reproduced with exact precision, minimizing variability and quality issues.

5. Durability and Surface Quality

The surface finish of robotic parts is more than just aesthetic—it directly impacts functionality. For example, smooth surfaces reduce friction in moving assemblies and improve wear resistance. CNC machining can achieve high-quality surface finishes without extensive secondary processes, prolonging the lifespan of robotic systems.

Applications of CNC Machined Parts in Robotics

Structural Frames and Brackets: Machined from aluminum or steel for lightweight strength and stability.

Gears and Transmission Systems: Precision-machined gears ensure smooth torque transmission and accurate movement.

Housings and Casings: CNC machining produces durable, sealed enclosures for motors, sensors, and electronics.

End Effectors and Grippers: Customized machining allows for highly specialized designs tailored to specific tasks.

Joint and Bearing Components: Tightly machined tolerances ensure seamless multi-axis movement without excess play.

CNC Machining vs. Alternative Methods

While additive manufacturing (3D printing) and casting are growing in popularity, they cannot yet replace CNC machining for most robotic parts. 3D printing excels in prototyping and lightweight designs but often falls short in material strength and surface finish. Casting is cost-effective for large volumes but lacks the precision and flexibility needed for robotics. CNC machining remains the most balanced approach—offering both high precision and material integrity.

The Future: CNC Machining and Robotics Innovation

As robotics advances into fields like collaborative robots (cobots), autonomous vehicles, medical robots, and humanoid systems, the demand for highly reliable components will only increase. CNC machining will continue to play a central role, but it is also evolving:

Integration with AI and IoT will enable smarter CNC operations with predictive maintenance and real-time monitoring.

Hybrid approaches combining additive manufacturing with CNC machining will reduce waste while maintaining precision.

Advanced tooling and coatings will extend tool life and improve machining performance for hard-to-cut materials.

These trends ensure that CNC machining will remain a cornerstone of robotic manufacturing, aligning with the industry’s drive toward precision, durability, and scalability.

Conclusion

CNC machining has earned its reputation as the gold standard for robotic parts manufacturing because it combines precision, versatility, repeatability, and quality in one robust process. As robots become more advanced and integrated into daily life, the demand for highly accurate and reliable components will only grow. Manufacturers who leverage CNC machining are not just producing parts—they are shaping the future of robotics.