The durability of steel, coupled with the ability of CNC machining to process hard materials, enables the production of robust and durable components. This makes CNC-machined steel parts highly suitable for applications requiring high strength and elasticity, such as the aerospace and automotive industries. Furthermore, CNC machining can achieve cost-effective production, especially for medium to high-volume production, as it minimizes material waste and labor costs. Overall, CNC machining stands out as the preferred method for steel processing in various engineering applications due to its high precision, versatility, efficiency, and affordability.

This article explores how CNC machining supports and enhances steel fabrication processes, focusing on its benefits, applications, and contributions to modern manufacturing.

Types Of Steel Used In CNC Machining

Due to its unique properties, various alloy steels are commonly used in CNC machining and are suitable for different application fields. Here are some commonly used alloy steels in CNC machining:

303 stainless steel: Known for its excellent machinability, it is commonly used to manufacture parts that require extensive processing. It has good corrosion resistance.

304 stainless steel: It has good corrosion resistance and is suitable for mechanical processing.

316 stainless steel: Known for its excellent corrosion resistance, it is commonly used in shipbuilding and chemical processing applications. It is also easy to process, but compared to 303 or 304, the processing difficulty may be greater.

1018 steel: a universal low-carbon steel with good machinability.

1045 steel: a medium carbon steel with higher strength and hardness than 1018 steel, suitable for manufacturing parts with higher requirements for strength and wear resistance.

4140 alloy steel: This chromium molybdenum alloy steel is known for its high strength and toughness, and is commonly used to manufacture components for the automotive and aerospace industries.

4340 alloy steel: Known for its excellent toughness and fatigue resistance, it is commonly used in the manufacture of gears and aircraft components.

8620 alloy steel: a low alloy carburizing steel known for its high surface roughness, commonly used in the manufacture of gears and other components that require a hard outer layer.

The above are just a few examples, and there are many other alloy steels with different properties that are suitable for CNC machining. The specific requirements of the project, such as strength, corrosion resistance, or machinability, will determine the steel alloy that is most suitable for your CNC machining application.

How CNC Machining Integrates Into Steel Fabrication

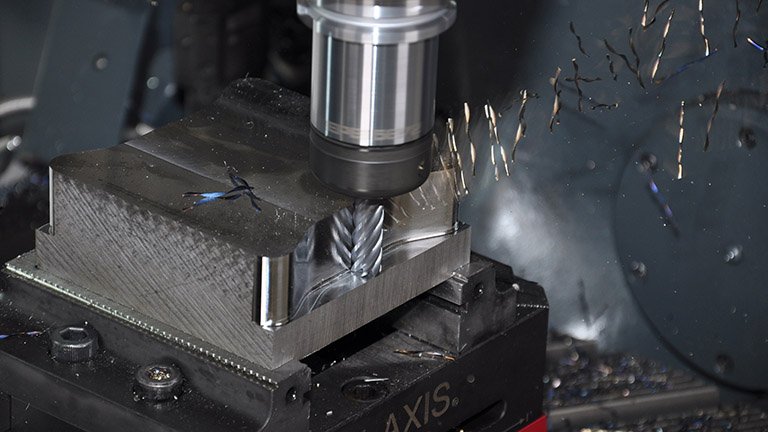

CNC machining brings computer-controlled precision to fabrication operations. By converting digital models into machine instructions (G-code), CNC machines can automate tasks such as:

- Milling

- Turning

- Drilling

- Boring

- Threading

- Tapping

- Slotting

These processes are used to remove material from steel workpieces to achieve the desired shape, holes, threads, or surface finish. CNC machining can be employed either as a primary shaping method or as a secondary process to refine components fabricated through other means (e.g., laser-cut blanks, welded structures).

Key Benefits of CNC Machining in Steel Fabrication

Unmatched Dimensional Accuracy

Steel components often require tight tolerances, especially in sectors like aerospace, automotive, or heavy equipment. CNC machining ensures consistent and repeatable accuracy down to microns, enabling critical parts to be produced within specification every time.

Design Flexibility

CNC machines can produce complex geometries that are difficult or impossible to achieve with manual fabrication tools. 3D contours, internal cavities, and compound angles can all be machined with high precision from steel billets or blanks.

Improved Production Efficiency

With advanced programming, high-speed cutting, and automated tool changes, CNC machines significantly reduce cycle times. Once the setup is complete, the system can operate with minimal human intervention, supporting lights-out manufacturing for steel parts.

Enhanced Repeatability

Whether producing five pieces or five thousand, CNC machining delivers consistent results. This is essential for OEMs and fabricators seeking interchangeable parts or serialized batch production with tight quality control.

Seamless Integration with CAD/CAM Systems

Steel fabrication shops can leverage digital workflows to go from CAD models directly to CNC machining with minimal manual translation. This streamlines prototyping, accelerates lead times, and minimizes errors in production.

Cost Reduction in High-Precision Fabrication

While initial setup costs for CNC machining may be higher, the reduction in scrap, rework, and manual labor quickly offsets those investments—particularly for high-volume or high-tolerance projects.

Applications of CNC Machining in Steel Fabrication

CNC machining plays a supporting or primary role in multiple areas of steel fabrication:

Structural Steel Components: CNC milling and drilling are used to prepare connection holes, slots, and counterbores for beams, plates, and brackets.

Automotive Parts: Gears, shafts, housings, and frames require tight tolerances and surface finish standards, achieved through CNC turning and multi-axis machining.

Machinery Frames and Housings: After welding, CNC milling helps achieve flatness, perpendicularity, and alignment of critical surfaces.

Tooling and Fixtures: High-strength steel fixtures are machined to ensure durability and accuracy in industrial applications.

Custom Assemblies: CNC machining allows fabrication shops to fulfill low-volume or specialized orders with minimal tooling costs.

The Challenge Of CNC Machining Steel

CNC machining of steel faces many challenges, such as tool wear due to hardness, heat generation that requires effective cooling, and differences in machinability between different steel alloys. The processing of work hardening and sharp chips during the manufacturing process increases complexity. It is crucial to achieve a smooth surface finish and maintain dimensional stability under residual stress. Choosing the best cutting tools, considering the wear resistance of steel, and maintaining the rigidity of the machine tool are crucial for the successful CNC machining of steel. Overcoming these challenges requires proficient programming, extensive experience, and adjusting strategies based on the specific steel alloy being processed.

Future Outlook: CNC and Smart Steel Fabrication

As steel fabrication becomes more digitized and data-driven, CNC machining is poised to play an even greater role. The integration of IoT, machine learning, and automated quality control will allow shops to monitor performance in real time, optimize toolpaths, and reduce downtime.

Robotics and CNC automation will also continue to bridge the gap between fabrication and machining, streamlining processes into a unified manufacturing cell. In the future, hybrid machines combining additive manufacturing and CNC machining may offer new capabilities for steel parts with complex internal structures or reduced material waste.

Conclusion

CNC machining has become a cornerstone technology in modern steel fabrication. It enhances precision, repeatability, flexibility, and efficiency—attributes essential for today’s demanding industrial applications. By integrating CNC machining into fabrication workflows, manufacturers can reduce lead times, improve part quality, and remain competitive in a global market.

For steel fabricators aiming to deliver high-performance parts and assemblies, investing in CNC technology is no longer optional—it is a strategic imperative.