In an age where flexibility, speed, and product differentiation are vital, custom manufacturing has emerged as a cornerstone of modern industrial strategy. Unlike mass production, which focuses on high volumes and standardized outputs, custom manufacturing is about tailoring parts, components, and products to exact customer specifications. It allows businesses to respond rapidly to evolving market demands, build prototypes efficiently, and create specialized solutions that deliver true value.

This article explores what custom manufacturing is, how it works, and why it’s increasingly essential across industries like aerospace, medical, automotive, and consumer electronics.

What Is Custom Manufacturing?

Custom manufacturing refers to the process of producing parts, assemblies, or complete products that are made to specific requirements rather than off-the-shelf designs. These projects often involve one-off pieces, low-volume batches, or highly specialized components that must meet strict dimensional, material, or performance standards.

Unlike traditional production lines, custom manufacturing workflows are agile and engineering-driven. Projects begin with customer drawings or CAD models, followed by material selection, process planning, CNC programming, fabrication, finishing, and inspection—every step tailored to the application.

Why Custom Manufacturing Matters

- Precision and Fit

Many industries require components that cannot be produced using generic specifications. Whether it’s a medical implant that must match patient anatomy or a high-tolerance aerospace bracket, custom machining ensures that every dimension, angle, and finish is dialed in for exact fit and function.

- Faster Prototyping and Iteration

Rapid product development relies on the ability to test, refine, and retest ideas. Custom manufacturing enables quick prototyping with CNC machining, 3D printing, or hybrid methods, helping engineers move from concept to working model in a matter of days—not weeks or months.

- Material Flexibility

Off-the-shelf parts may not offer the right material performance. Custom manufacturing gives designers access to a wide range of materials—metals, plastics, composites—ensuring the chosen material supports performance, weight, corrosion resistance, and cost goals.

- Agility in Low-Volume Production

For small and medium-sized businesses, custom manufacturing eliminates the need for high-volume orders to justify production. It supports flexible production quantities while maintaining high quality, making it ideal for startups, research labs, and specialized industries.

Technologies That Enable Custom Manufacturing

Custom manufacturing is powered by a range of advanced technologies:

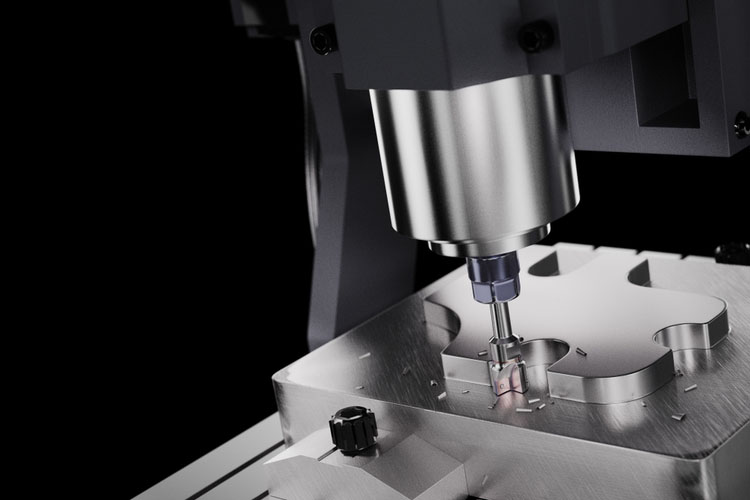

CNC Machining: Offers unmatched precision for turning, milling, drilling, and threading complex geometries across metals and plastics.

3D Printing (Additive Manufacturing): Allows for complex internal geometries, lightweight structures, and rapid iterations without the need for tooling.

Laser Cutting and Waterjet: Enable high-speed cutting of sheet materials with fine detail and minimal heat distortion.

Sheet Metal Fabrication: Useful for enclosures, panels, and brackets where flexibility in design and dimension is required.

CAD/CAM Software: Converts design files into machine-readable code, streamlining the process from design to part.

These technologies work together to support on-demand, highly configurable production environments that can handle both prototypes and production parts.

Industries That Rely on Custom Manufacturing

Aerospace: Lightweight structural parts, engine components, test fixtures

Medical: Custom implants, surgical tools, orthopedic trial devices

Automotive: Custom engine mounts, performance upgrades, low-run components

Robotics & Automation: Custom brackets, gearboxes, housings

Electronics: Precision-machined enclosures, connectors, cooling systems

Consumer Products: Custom prototypes, packaging, accessories, and tooling.

Factors to Consider When Choosing a Custom Manufacturer

Professional knowledge and service scope

When choosing a custom manufacturer, it is important to evaluate their service scope and expertise in specific manufacturing technologies. Manufacturers with multiple capabilities, such as CNC machining, precision machining, and 3D printing, can provide significant advantages. This diversity enables them to handle various types of production processes, whether it’s subtractive manufacturing or additive manufacturing, and to be more flexible in meeting your specific needs.

Reputation and customer feedback

When choosing a custom manufacturer, reputation and customer feedback should be the primary considerations. Comments, case studies, and recommendation letters from previous customers can provide valuable insights into the reliability, quality, and consistency of manufacturers. Investigating their past projects and successful cases will give you a clearer understanding of how they respond to different manufacturing needs and challenges.

Material and process quality

The quality and craftsmanship of materials used in customized manufacturing are crucial considerations. Even with the latest technology, advanced equipment, and cutting-edge manufacturing processes, skilled labor plays a crucial role in ensuring high-quality products. Manufacturers must rely on consistent raw materials and professional manufacturing processes to meet the required product specifications.

It is essential to verify the manufacturer’s certification and testing capabilities to ensure that their materials meet your application requirements. Certification can give you peace of mind that the materials used have the highest quality and comply with relevant industry standards. In addition, comprehensive incoming inspection and final testing are crucial for preventing defects and ensuring that the final product meets your exact requirements.

Delivery lead time and delivery schedule

Delivery lead time and delivery schedule are key factors in choosing a manufacturer. It is essential to make a realistic estimate of the production schedule, including the time required for prototype production and any necessary revisions.

Be sure to discuss potential delays and the manufacturer’s response plan in advance. A reputable manufacturer will engage in transparent communication regarding any potential issues and provide updates throughout the entire process.

Communication and Collaboration Practice

You should establish a transparent, regular update mechanism and clear contact points from the beginning. This ensures that both parties have a common understanding of customer needs and product specifications. Open communication helps to avoid misunderstandings, reduce delays, and maintain high-quality products.

The Future of Custom Manufacturing

As supply chains become more complex and product personalization becomes a key differentiator, custom manufacturing will continue to grow. Emerging trends include:

Cloud-based Manufacturing Platforms: Allowing customers to upload designs, get instant quotes, and manage orders digitally

AI in Quoting and Design Optimization: Helping customers get faster feedback and better designs

Sustainable Practices: Reducing waste and energy consumption through digital-first, low-inventory production

Conclusion

Custom manufacturing is not just about building parts to order—it’s about enabling innovation, flexibility, and speed in a world where product lifecycles are shorter and consumer expectations are higher. Whether you’re prototyping a new idea or scaling a low-volume product, custom manufacturing ensures that you can get exactly what you need, when you need it, and with the precision that modern applications demand.