Manufacturing is entering a transformative era shaped by precision, speed, digital intelligence, and sustainability. In this rapidly evolving landscape, CNC (Computer Numerical Control) machining stands out as one of the foundational technologies empowering the next generation of industrial progress. From aerospace to automotive, from healthcare to consumer electronics, CNC machining continues to push the limits of what can be manufactured with efficiency and accuracy.

As manufacturing embraces digital transformation and Industry 4.0, this article explores how CNC machining is at the forefront of this shift—reshaping processes, redefining quality standards, and fueling innovation.

The Role of CNC Machining in Modern Industry

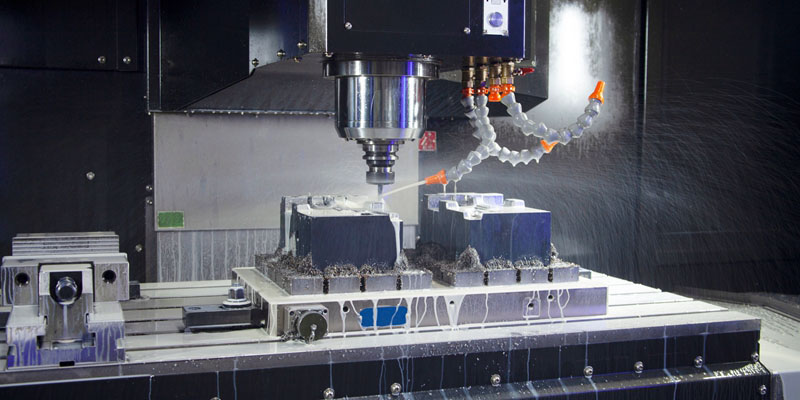

CNC machining automates the control of cutting tools via computer programming. Unlike manual methods, it ensures consistent repeatability, tight tolerances, and reliable output across production runs. This precision makes it ideal for both prototyping and large-scale manufacturing, across a broad spectrum of industries.

What makes CNC machining especially future-proof is its adaptability. Whether producing lightweight aerospace structures or medical implants with micro-level detail, CNC machines can handle a wide range of materials—from metals and alloys to composites and engineered plastics—with unparalleled accuracy.

Emerging Trends Driving the Future of CNC Machining

1. Industry 4.0 Integration

CNC machines are increasingly becoming part of a smart, connected manufacturing ecosystem. Through IoT-enabled sensors, data from CNC machines can be collected in real-time—monitoring performance, predicting maintenance needs, and reducing unexpected downtime.

This digital integration allows factories to:

- Track production in real-time

- Improve decision-making through data analytics

- Automate quality assurance with sensor-based feedback

- Connect CNC machines to ERP and MES systems for seamless coordination

2. Advanced Multi-Axis Capabilities

The development of 5-axis and even 9-axis CNC machines allows manufacturers to produce more complex geometries in fewer setups. This not only reduces time and tooling costs but also improves dimensional accuracy by minimizing repositioning errors.

For industries requiring intricate parts—like turbine blades, orthopedic implants, or advanced vehicle components—multi-axis CNC machining provides unmatched flexibility and scalability.

3. Hybrid Manufacturing

CNC machining is increasingly being integrated with additive manufacturing. By combining subtractive (CNC) and additive (3D printing) methods, manufacturers can optimize both material usage and structural performance.

For example, a metal part may be 3D printed to a near-net shape and then finished using CNC turning or milling. This hybrid approach reduces waste, shortens lead times, and supports innovative product design.

4. Artificial Intelligence and Automation

Artificial intelligence is reshaping how machining is programmed and optimized. Machine learning algorithms can analyze tool wear patterns, adjust feed rates in real time, and even detect defects as they occur. AI also enhances CAM software, offering automated toolpath generation and adaptive control for smarter operations.

Combined with robotic automation and automated tool changers, these systems enable “lights-out manufacturing,” where machines operate continuously with minimal human oversight.

Sustainability in CNC Manufacturing

Sustainability is no longer optional—it’s a competitive necessity. CNC machining contributes to greener production in several ways:

Material Efficiency: By producing components with tight tolerances, CNC processes minimize scrap and rework.

Dry Machining and MQL: These coolant-reduction techniques limit environmental impact and lower chemical disposal costs.

Energy Monitoring: Modern machines can optimize energy use and reduce idle power consumption.

Recyclable Materials: Many CNC-machined metals like aluminum and stainless steel can be reclaimed and reused.

As manufacturers face growing pressure to meet carbon-neutral goals, CNC machining will be a critical tool in building sustainable production models.

Customization and Agile Manufacturing

With rising demand for customized, small-batch, and rapid-turnaround products, CNC machining offers unmatched agility. Manufacturers can quickly move from CAD model to finished part with minimal lead time.

This flexibility supports:

- On-demand production

- Design iterations and prototyping

- Low-volume, high-mix workflows

- Precision medical and aerospace components tailored to specific requirements

Cloud-based collaboration and CAD/CAM platforms further streamline this process by enabling teams across locations to design, program, and launch production seamlessly.

Challenges and Future Outlook

Despite its strengths, CNC machining faces several challenges moving forward:

Talent Shortage: The industry requires more skilled machinists, programmers, and engineers familiar with digital workflows.

Initial Investment: High-end CNC machines, software, and automation systems require substantial upfront capital.

Cybersecurity: As machines become more connected, securing sensitive production data becomes critical.

However, these challenges also create opportunities—for education providers, technology developers, and forward-thinking manufacturers—to innovate and evolve.

Conclusion

The future of manufacturing is being shaped by technologies that combine precision, adaptability, and digital intelligence—and CNC machining is central to that evolution. From its roots in subtractive processes to its integration with AI, IoT, and additive manufacturing, CNC is no longer just about cutting metal—it’s about enabling innovation at every level of design and production.

As industries race toward smarter, leaner, and more sustainable practices, CNC machining offers the tools, the data, and the flexibility to meet the demands of tomorrow. It doesn’t just make parts; it makes progress possible.