Step turning is a fundamental yet highly significant operation in lathe-based machining, especially within CNC turning processes. This technique is essential for creating cylindrical components with varying diameters along the same axis, often referred to as stepped shafts or multi-diameter parts. Whether in the production of automotive transmission shafts, motor housings, or aerospace components, step turning plays a critical role in delivering dimensional accuracy and functional geometry.

This article explores the step turning process in depth—covering its working principles, tooling requirements, benefits, and industrial applications—providing a clear understanding for engineers, machinists, and manufacturers alike.

What Is Step Turning?

Step turning is a lathe machining operation used to create a series of cylindrical surfaces with different diameters along a single axis. Each “step” in the component represents a change in diameter, often defined by specific lengths and tolerances. These stepped geometries may serve various functions, such as:

- Allowing components to fit into different housings or bearings

- Accommodating seals, threads, or gears

- Providing shoulder surfaces for axial location or load support

In modern CNC environments, step turning is performed with high precision using pre-programmed cutting paths that ensure consistent dimensional control, even over large production runs.

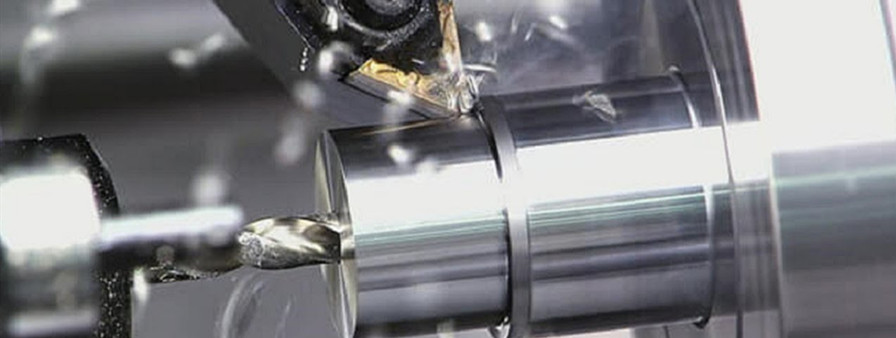

Step Turning Process Overview

The step turning process involves the following key stages:

- Workpiece Setup: The raw material—usually a round bar—is secured in the chuck or collet of a CNC lathe.

- Program Input: The CNC program defines the different diameters, lengths, and transitions between steps. Tool paths, feed rates, and spindle speeds are determined by the material and desired finish.

- Tool Engagement: A turning tool is fed along the axis of the rotating workpiece to remove material and create the desired step.

- Transition Cuts: Transitions between steps may involve sharp shoulders or fillets, depending on the design.

- Final Finishing: Secondary tools or passes may be used to improve surface finish or refine critical dimensions.

The entire process may include roughing and finishing passes, depending on material removal rates and tolerance requirements.

Tools Used in Step Turning

Proper tooling is essential for achieving clean, accurate step transitions and consistent surface finishes. Common tools include:

- Turning Inserts: Carbide or ceramic inserts with square or round profiles are widely used for roughing and finishing steps.

- Profile Tools: Custom tools may be used for stepped profiles with fillets or compound geometries.

- Grooving Tools: When sharp transitions or reliefs are required between steps, grooving tools help define precise boundaries.

- Back Turning Tools: These are used when access to rear-facing steps is needed, especially in components with undercuts or reverse steps.

Tool selection depends heavily on workpiece material, required tolerances, and surface finish standards.

Materials Suitable for Step Turning

Step turning can be applied to a wide range of materials including:

- Metals: Steel, stainless steel, aluminum, brass, titanium

- Plastics: Nylon, PEEK, PVC, and other engineering polymers

- Composites: Fiber-reinforced materials used in aerospace and automotive applications

Material machinability influences tool wear, chip control, and achievable surface finish, all of which must be considered in tooling and parameter selection.

Benefits of Step Turning

Dimensional Precision: CNC step turning provides tight control over diameters and lengths, ensuring consistent part quality.

Versatility: A wide range of geometries can be produced, from simple stepped shafts to complex multi-level profiles.

Efficiency: Multiple steps can be machined in a single setup, reducing changeover time and enhancing throughput.

Improved Fit and Function: Stepped features allow for precise assembly with bearings, seals, or mating components.

Applications of Step Turning

Step turning is widely used across various sectors. Here are some typical examples:

- Automotive Industry

Stepped shafts are common in engines, gearboxes, and suspension systems. These components often require precise transitions for bearings, gears, or pulleys.

- Aerospace Components

Aircraft components such as actuator shafts and turbine parts rely on stepped profiles for assembly with lightweight yet high-strength materials.

- Electrical and Motor Assemblies

Electric motor shafts frequently have multiple steps to accommodate armatures, couplings, and fastening components.

- Industrial Machinery

Rotating shafts, rollers, and drive components often use step turning to create functional interfaces across their length.

- Medical Devices

Implants and surgical instruments may feature stepped geometries to match anatomical profiles or assembly systems.

Design and Machining Considerations

To ensure optimal results in step turning operations, the following factors must be considered:

- Transition Geometry: Sharp shoulders vs. radiused steps can affect stress distribution and assembly fit.

- Tolerance Stack-Up: Accumulated errors between steps can lead to misalignment; CNC control mitigates this but proper inspection is essential.

- Surface Finish Requirements: For critical mating surfaces, secondary finishing such as grinding or polishing may be needed.

- Toolpath Strategy: Optimized toolpaths reduce cycle time and minimize tool wear.

Conclusion

Step turning remains one of the most fundamental yet powerful operations in CNC machining, enabling the production of functional, precise, and complex cylindrical components. As CNC technologies advance—offering better tooling, multi-axis control, and smart process monitoring—step turning will continue to evolve as a reliable solution for high-precision industries.

Whether you’re designing automotive drive shafts, aerospace actuators, or high-performance medical parts, understanding the principles and best practices of step turning is essential to ensuring optimal performance, quality, and manufacturability.