Surface finishing is a vital step in manufacturing, especially for components that must meet both aesthetic and functional requirements. Two of the most common finishing methods—powder coating and anodizing—serve the same broad purpose: protecting parts from corrosion, wear, and environmental damage. Yet, their chemistry, processes, and performance differ significantly. Understanding these differences helps engineers and designers choose the best option for a specific application.

Understanding the Processes

Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on the surface of aluminum or other non-ferrous metals. The part is submerged in an acid electrolyte bath and subjected to an electric current, which converts the surface into a controlled layer of aluminum oxide.

This oxide layer is integrated into the metal, not just coated on top, providing excellent adhesion and corrosion resistance. After anodizing, parts can be dyed in various colors and sealed to enhance durability.

Powder Coating

Powder coating, on the other hand, is a mechanical and thermal coating process. It involves applying a dry, electrostatically charged powder—typically composed of resins, pigments, and additives—to a metal surface. The coated part is then baked in an oven, where the powder melts and chemically bonds into a smooth, continuous film.

Unlike anodizing, powder coating creates a thick protective layer on top of the surface, forming a robust shield against scratches, UV exposure, and corrosion.

Key Differences Between Powder Coating and Anodizing

a) Material Compatibility

Anodizing: Primarily suitable for aluminum, magnesium, and titanium. It chemically alters the surface of the metal and cannot be applied to steel or most other ferrous alloys.

Powder Coating: Can be used on a wide range of metals, including steel, aluminum, brass, and zinc. It provides excellent protection for materials that cannot be anodized.

b) Durability and Corrosion Resistance

Anodizing: Offers excellent corrosion protection due to its oxide layer, especially when sealed. However, it can be susceptible to damage from alkaline environments or abrasion if unsealed.

Powder Coating: Forms a thicker, more impact-resistant layer. It’s less likely to scratch or chip under typical handling, making it ideal for outdoor and industrial applications.

c) Appearance and Finish

Anodizing: Provides a metallic, satin, or matte finish that enhances the natural appearance of aluminum. It allows the metal texture to show through and can be dyed in many colors with consistent tone.

Powder Coating: Offers a wider color palette and multiple finish options—glossy, matte, textured, or metallic. The coating completely covers the substrate, allowing for more decorative effects but hiding the natural metal texture.

d) Thickness and Dimensional Impact

Anodizing: Very thin, typically 5–25 µm for standard coatings and up to 50 µm for hard anodizing. It causes minimal dimensional change, making it suitable for tight-tolerance parts.

Powder Coating: Much thicker, ranging from 50–150 µm, which can slightly affect critical dimensions. Therefore, it’s not ideal for precision-fit assemblies without proper design compensation.

e) Wear and Scratch Resistance

Anodizing: Hard anodized layers are exceptionally wear-resistant, suitable for sliding or high-contact surfaces such as aerospace components or mechanical housings.

Powder Coating: Although more flexible, it is generally less wear-resistant than hard anodizing and can chip or peel if impacted.

f) Maintenance and Longevity

Anodized surfaces require minimal maintenance and resist fading over time. Since the color is integrated into the oxide layer, it doesn’t peel or flake.

Powder-coated surfaces are also low maintenance but may degrade faster under prolonged UV exposure unless UV-stabilized powders are used.

Cost Considerations

Anodizing is typically more cost-effective for aluminum parts in large quantities, particularly when high precision or corrosion protection is the goal.

Powder coating may involve higher upfront costs due to equipment and curing requirements but offers better versatility and color customization across different materials.

For parts requiring decorative appeal and durability (such as architectural panels or furniture), powder coating provides better ROI. For technical parts demanding dimensional precision (like aerospace, electronics, or automotive components), anodizing is often the better investment.

Common Applications

The decision between powder coating and anodizing should be driven entirely by the application’s requirements.

Choose Powder Coating When:

- The part is made of steel or another non-aluminum metal.

- High impact resistance is the most important durability factor (e.g., automotive wheels, outdoor furniture, bike frames).

- A specific opaque color or texture is required to match a brand or design aesthetic.

- The part does not have extremely tight dimensional tolerances.

- Cost is a primary driver, as powder coating is often more economical for general applications.

Choose Anodizing When:

- The part is made of aluminum.

- Superior hardness, wear, and scratch resistance are critical (e.g., high-wear machine components, premium electronics housings, cookware).

- Maintaining precise dimensions and tight tolerances is non-negotiable (e.g., threaded parts, bearing fits).

- A premium, metallic aesthetic is desired, showcasing the quality of the base metal.

- The part requires excellent UV resistance for outdoor applications.

Environmental Impact

Both methods are more eco-friendly compared to solvent-based liquid paints, but they differ in details:

Anodizing uses water-based electrolytes and produces minimal waste. However, managing acid baths and metal salts requires proper recycling and neutralization.

Powder coating generates almost no volatile organic compounds (VOCs), and unused powder can be recycled, making it one of the cleanest industrial coating processes.

How to Choose Between Them

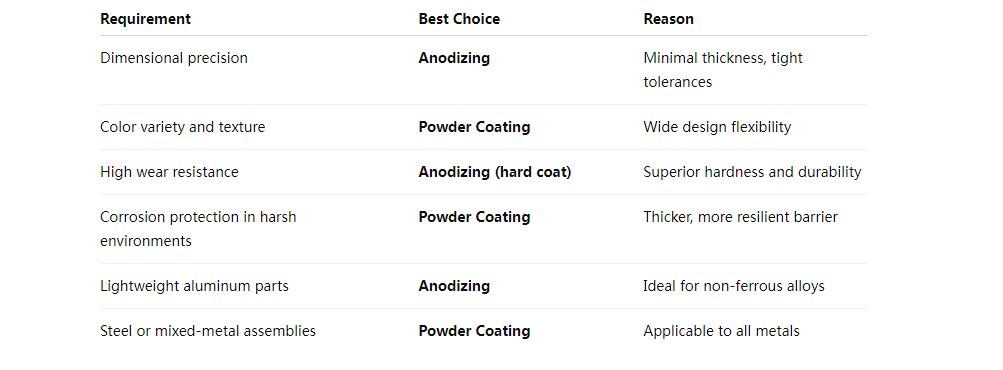

When selecting between powder coating and anodizing, consider the following:

Conclusion

Both powder coating and anodizing offer distinct benefits, and the right choice depends on material, application, and performance priorities.

Anodizing excels in precision, wear resistance, and preserving the natural metallic appearance.

Powder coating stands out for its versatility, color options, and robust surface protection.

For manufacturers seeking both aesthetic appeal and long-term durability, combining both technologies can sometimes yield the best results—for instance, anodizing for critical aluminum components and powder coating for steel assemblies within the same product line.

In the end, understanding each process’s strengths ensures that every machined or fabricated part not only performs efficiently but also maintains its finish for years to come.