Machining is a critical process in modern manufacturing, used to create precise parts across a range of industries. While metal machining is traditionally more common, the demand for plastic machining has grown rapidly due to advancements in engineering plastics and increasing requirements for lightweight, corrosion-resistant components.

Although both materials can be machined using similar CNC equipment, the processes differ significantly in terms of cutting behavior, tooling requirements, and design tolerances. Understanding the differences between plastic machining and metal machining is essential for engineers, designers, and machinists aiming to optimize both cost and performance.

Material Properties: The Foundation of Machining Behavior

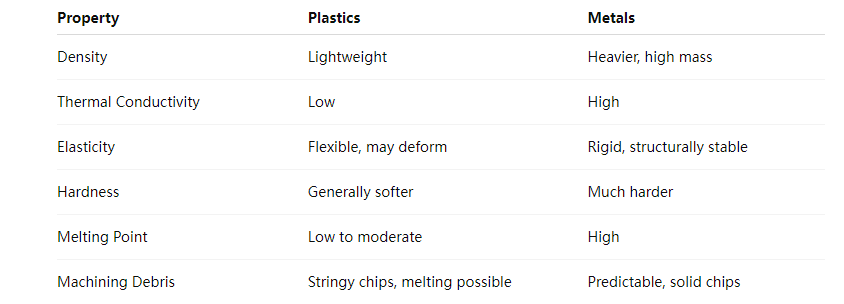

The most fundamental differences stem from the inherent material characteristics of plastics and metals:

There are significant differences in the physical properties of plastics and metals. In most cases, metals are harder and more durable than plastics, which makes them more difficult to machine. This means that metal machining requires more specialized equipment and tools than plastic machining. On the other hand, for plastic machining, standard cutting tools will do just fine.

In terms of cost, plastics are generally much cheaper than metals. Therefore, this makes plastics a more cost-effective choice for many applications. This is a benefit especially for large-scale production runs where significant cost savings can be achieved. However, plastic parts are not always suitable for all applications. If a part needs to withstand high temperatures or pressures, or needs to be highly resistant to corrosion, metal may be a better choice.

Tooling and Cutting Parameters

Tool Material and Geometry

Plastic machining typically uses high-speed steel (HSS) or sharp carbide tools with polished surfaces to minimize heat and avoid material smearing or tearing.

Metal machining, especially for harder alloys, requires more durable coated carbide or even ceramic and CBN tools for extended tool life and heat resistance.

Feeds and Speeds

Higher spindle speeds and lighter feed rates are often used in plastic machining to prevent material deflection or heat buildup.

Metal machining usually demands slower spindle speeds and heavier feeds, depending on hardness and tool capacity.

Chip Evacuation and Cooling

Plastics can melt or fuse to the tool if not properly cooled. Air blast or minimal coolant is preferred to avoid stress cracking or chemical reaction.

Metals benefit from flood coolant or high-pressure coolant systems to control temperature and extend tool life.

Tolerances and Dimensional Stability

Plastic parts tend to be more sensitive to thermal expansion, moisture absorption, and machining-induced stress.

Plastics may creep, warp, or shrink post-machining, especially without post-process annealing. Tolerances of ±0.05 mm are typical, but may need adjustment for hygroscopic materials like nylon.

Metals, being more dimensionally stable, allow for tighter tolerances—often up to ±0.01 mm or better in high-precision machining.

Thus, designers must factor in the plastic’s long-term behavior in real-world applications, not just its as-machined dimensions.

Surface Finish and Aesthetics

Plastic surfaces are more prone to scratching, but easier to polish or texture for cosmetic appeal.

Burrs are common in both, but deburring plastic may require gentler methods (e.g. cryogenic or hand trimming) to avoid edge damage.

Metals can achieve mirror-like finishes through polishing or grinding, but this often requires more time and tooling wear.

Expertise and Equipment

Plastics machining requires expertise and equipment that may not be available in all manufacturing facilities. Additionally, plastic parts can be more difficult to process than metal parts, which means that producing them may require more time and resources. Metal processing, on the other hand, is a more established process that is widely used in many different industries. Therefore, there is usually more expertise and equipment involved in metal processing than in plastic processing.

Applications of Metal Parts vs. Plastic Parts

The choice between plastic machining and metal machining ultimately depends on the specific application and the performance characteristics required. For example, for parts that require a high degree of design flexibility, such as custom housings or consumer products, plastic machining may be a better choice. On the other hand, for parts that need to withstand high temperatures, pressures, or corrosive environments, such as automotive or aerospace components, metal machining may be the preferred choice.

Conclusion

Both plastic and metal machining are essential to modern manufacturing, but they are not interchangeable. Each material presents unique challenges and benefits, requiring tailored machining strategies, tools, and design considerations.

By understanding the core differences in machining behavior, tolerancing, and post-processing, manufacturers can make smarter decisions that align with application needs, cost targets, and performance expectations. Whether it’s a lightweight POM gear or a hardened steel fixture, choosing the right material and machining approach is key to successful production.