In the world of product development, the path from a single prototype to a full-scale production run of millions is often seen as a linear journey. However, a critical and increasingly vital stage exists between these two extremes: low-volume manufacturing. This strategic approach bridges the gap between one-off prototyping and mass production, offering a powerful combination of speed, flexibility, and cost-effectiveness that is essential for modern innovation.

For companies developing custom hardware, specialized equipment, or launching products in niche markets, low-volume manufacturing is not just a stepping stone—it is often the final destination. This guide explores what low-volume manufacturing is, the technologies that enable it, and why it has become an indispensable strategy for custom production.

What is Low-Volume Manufacturing?

Low-volume manufacturing is the production of end-use parts in quantities that are too large for prototyping but too small to be economically viable for traditional mass-production tooling. While the exact numbers vary, this “sweet spot” typically ranges from 100 to 10,000 units.

Unlike prototyping, which focuses on testing form and function, low-volume manufacturing is about creating market-ready products. It utilizes real production-grade materials and processes to deliver parts that are identical in quality and performance to what would be expected from a full-scale run, but without the massive upfront investment and long lead times.

The Strategic Advantages of a Low-Volume Approach

- Accelerating Time-to-Market

In today’s fast-paced markets, speed is a significant competitive advantage. Setting up hard tooling (e.g., steel injection molds) for mass production can take months. Low-volume manufacturing methods, such as CNC machining or rapid tooling, can deliver thousands of production-quality parts in just a few weeks. This allows companies to launch their products, capture market share, and start generating revenue much faster.

- Unparalleled Design Flexibility

Committing to mass production tooling locks in a design. Any subsequent changes, whether minor tweaks or major improvements, require costly and time-consuming modifications to the tooling. Low-volume manufacturing keeps the design fluid. It allows engineers to make iterative improvements between production batches based on user feedback or further testing, ensuring the final product is truly optimized before scaling up.

- Bridging the Financial Gap

The cost difference between prototyping and mass production is immense. A prototype might cost a few hundred dollars, while a set of production molds can cost tens or even hundreds of thousands. Low-volume manufacturing provides a financially viable intermediate step. It avoids the high per-unit cost of prototyping while deferring the massive capital expenditure of hard tooling, reducing financial risk and improving cash flow.

- Effective Inventory and Risk Management

Mass production often requires a company to commit to producing tens of thousands of units to achieve a reasonable price-per-part. This creates a significant risk of overproduction, especially for new or niche products. Low-volume manufacturing allows you to produce only what you need, minimizing inventory costs and reducing the risk of being left with obsolete stock if the market demand doesn’t meet forecasts.

Key Technologies Driving Low-Volume Production

Several advanced manufacturing technologies are at the heart of the low-volume revolution.

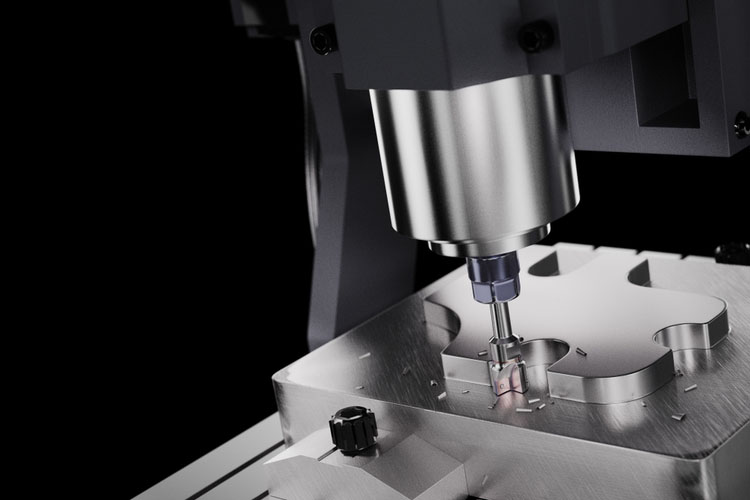

CNC Machining: The cornerstone of low-volume manufacturing for metal and high-performance plastic parts. With no tooling investment required, CNC machining is perfectly suited for producing anywhere from one to several thousand identical, high-precision components directly from a CAD file.

Rapid Tooling (or Bridge Tooling): This is a faster, more cost-effective version of injection molding. Instead of using hardened steel, molds are machined from aluminum. These aluminum molds are much quicker and cheaper to produce but have a shorter lifespan (typically 5,000-10,000 cycles). This makes them the perfect “bridge” solution for low-volume injection molding needs.

Urethane Casting (Vacuum Casting): An excellent process for producing high-quality, rigid or flexible plastic parts in quantities from a dozen up to a few hundred. A master pattern (often 3D printed or machined) is used to create a soft silicone mold. This mold can then be used to cast parts with a finish and texture that can rival injection molding, but at a fraction of the tooling cost.

3D Printing (Additive Manufacturing): Once limited to prototyping, industrial 3D printing technologies like Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS) can now produce durable, end-use parts. For very low volumes (under 100) or parts with extremely complex geometries, additive manufacturing is often the most efficient choice.

When is Low-Volume Manufacturing the Ideal Solution?

This approach is not just a temporary phase but a long-term strategy for many businesses. It is the perfect fit for:

Niche and Custom Products: For industries like aerospace, medical devices, and robotics, where products are highly specialized and produced in limited quantities.

Early Market Entry: To test a market with a real product and gather user feedback before committing to a full-scale launch.

Bridge Production: To serve as a production method that generates revenue while the long-lead-time tooling for mass production is being prepared.

Part Consolidation and Complex Designs: When a part is so complex that it can only be made efficiently with a process like 5-axis CNC machining or additive manufacturing, making low-volume the only viable option.

Comparing Low-Volume and High-Volume Production

Both models aim to produce goods, but they serve different business objectives. Comparing low-volume and high-volume manufacturing models can help determine which best suits your business needs. Low-volume models prioritize flexibility and small batch sizes, while high-volume models focus on achieving cost savings through large-scale output.

Production Planning and Lead Times

In low-volume production, operational adjustments to production plans can be easily implemented. Design or demand changes do not disrupt operations. Combined with fast, responsive lead times, this creates a perfect combination of flexibility and agility to meet customer needs.

Large-volume production reduces flexibility. Changing or stopping a batch mid-production is difficult and expensive. In addition to tooling, batch settings also increase lead times.

Cost Impact

Manufacturing cost is a key consideration when choosing a model. Small batch production can reduce unit costs, but it also increases equipment commissioning expenses. Large-volume production can lower unit costs through economies of scale, but it requires significant upfront investment in tooling and equipment installation. If you don’t need to produce thousands of units, small batches are more cost-effective in the long run.

The Challenges of Low-Volume Manufacturing and How to Overcome Them

Every system has its drawbacks. While low-volume manufacturing offers its benefits, this type of manufacturing also presents challenges. Companies may encounter challenges such as high part costs, slow automation processes, complex supplier relationships, or specialized equipment. However, these obstacles can be overcome.

Strategic Supplier Selection

Every company relies on at least one trusted supplier. They must focus on short runs and efficient CAD/CAM systems that produce geometric accuracy and reliability. Not all partners offer this level of service, so choose wisely.

Adopting New Technologies

Automation is often designed with scale in mind. However, with the right tools, automation can be applied even to small-scale operations. Using flexible manufacturing systems and CNC machining aids can reduce labor time and increase productivity, even on a smaller scale.

Conclusion

Low-volume manufacturing has fundamentally changed the landscape of product development. It empowers innovators, startups, and established companies alike to bring customized, high-quality products to market with greater speed, less risk, and more creative freedom than ever before. By providing a strategic and agile alternative to the rigidities of mass production, it serves as a powerful engine for custom innovation in an increasingly on-demand world.