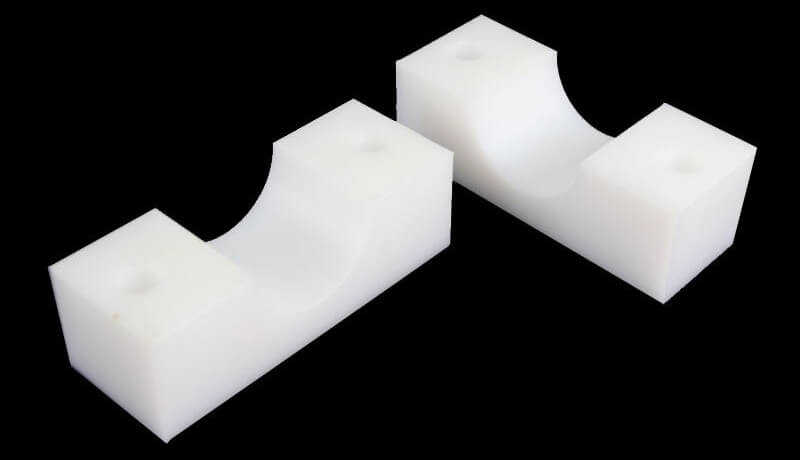

Choosing the right plastic material for CNC machining is essential for achieving the desired balance of performance, precision, durability, and cost. Two of the most common engineering plastics used in CNC machining are HDPE (High-Density Polyethylene) and Delrin (Acetal, POM).

While they may look similar on a spec sheet to the untrained eye, they behave very differently under a cutting tool and in real-world applications. Understanding these differences helps engineers select the optimal material for any manufacturing project.

In this guide, we break down the differences between HDPE and Delrin, focusing on their machinability, mechanical properties, and ideal use cases to help you select the best material for your next project.

What is HDPE?

HDPE is a semi-crystalline thermoplastic known for its high strength-to-density ratio. It is one of the most versatile plastics in the world, found in everything from milk jugs to corrosion-resistant piping. It is known for its excellent impact strength and moisture resistance, making it ideal for outdoor, marine, and chemical-related applications. Its softness, however, means it can deform under heat or cutting forces if the machining process is not carefully controlled.

What is Delrin? (Acetal / POM)

Delrin (Acetal, POM) is a high-performance engineering plastic prized for its strength, stiffness, low friction, and exceptional dimensional stability. It behaves similarly to metal during machining and supports tight tolerances, making it ideal for mechanical components that require precision and load-bearing performance. It bridges the gap between plastics and metals, offering high stiffness and low friction.

Head-to-Head Comparison: The Critical Factors

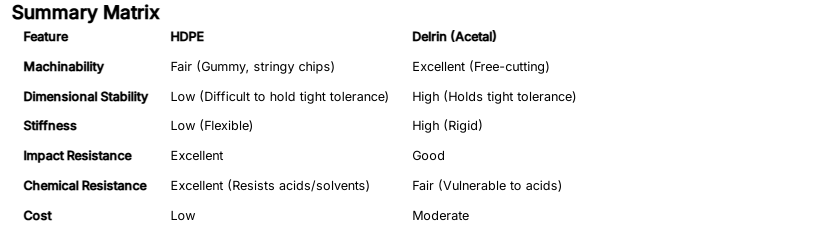

1. Machinability and Tolerances

Delrin has excellent machinability, while HDPE can be challenging. Delrin cuts cleanly, produces predictable chips, and allows us to hold very tight tolerances easily. HDPE tends to be soft and ‘gummy’, producing stringy chips that can wrap around tooling.

Delrin: Because it is stiff and hard, it resists deflection during machining. It can be turned, milled, and drilled with speeds and feeds similar to soft brass. You can achieve a superb surface finish right off the machine with minimal deburring required.

HDPE: It requires sharp tools and high rake angles to slice the material rather than plow through it. It is difficult to clamp tightly without deforming the part, and it creates long, stringy chips that can wrap around tooling. Achieving a glass-smooth finish on HDPE is difficult, it usually retains a matte, waxy texture.

2. Strength and Stiffness

Delrin: It has a high tensile strength (approx. 10,000 psi) and is very rigid. It is excellent for structural parts like gears, bushings, and fittings that must hold their shape under load.

HDPE: It has a lower tensile strength (approx. 4,000 psi) and is much more flexible. However, HDPE excels in impact resistance. If you hit a Delrin part with a hammer, it might crack, an HDPE part will likely absorb the blow and rebound.

3. Temperature Resistance

Delrin has a higher continuous service temperature than HDPE. Delrin can operate comfortably up to around 90°C (194°F), while HDPE starts to lose its structural integrity at around 65°C (150°F), although it remains stable at very low temperatures.

4. Chemical and Moisture Resistance

HDPE: This is the champion of chemical resistance. It is virtually immune to solvents, acids, and harsh cleaning agents. Furthermore, it has near-zero moisture absorption, making it ideal for marine environments or fluid handling.

Delrin: While Delrin has good moisture resistance, it is not as absolute as HDPE. More importantly, Delrin cannot be used with strong acids or chlorine-based chemicals, as they will degrade the material rapidly (a phenomenon known as “acid hydrolysis”).

5. Friction and Wear

Delrin: Naturally lubricious. It is one of the best materials for sliding parts (bearings, slides, gears) because it has a very low coefficient of friction against metals.

HDPE: Also slippery (waxy feel), making it good for wear strips and conveyor guides. However, for high-cycle precision moving parts, Delrin usually offers better wear life.

6. Cost

Raw Material: HDPE is significantly cheaper than Delrin (often 30-50% less by volume).

Machining Cost: This is where the equation gets tricky. While HDPE is cheaper to buy, Delrin is faster to machine. For complex parts requiring tight tolerances, the labor time saved by using Delrin often offsets the higher material cost.

Common Applications

HDPE Applications

- Fluid handling components

- Chemical tanks, pipes, and fittings

- Outdoor or marine equipment

- Protective covers and housings

- Food-grade components (FDA-approved grades available)

HDPE is ideal where flexibility, chemical resistance, or cost efficiency is required.

Delrin Applications

- Precision gears and sprockets

- Bushings, bearings, and rollers

- High-load mechanical components

- Automotive interior mechanisms

- Snap-fit parts requiring dimensional accuracy

- Industrial machine components

Delrin is selected for applications requiring high strength and tight tolerances.

The Verdict: Which Should You Choose?

Choose HDPE if:

You are designing fluid handling components (tanks, plugs, piping).

The part will be exposed to harsh chemicals or acids.

Impact resistance is more important than tensile strength.

Cost is the primary driver and tolerances are loose (±.005″ or greater).

Choose Delrin if:

You are making mechanical parts like gears, screws, bushings, or housing.

You need tight tolerances (±.002″ or better).

The part requires high stiffness and structural integrity.

You need a superior surface finish for aesthetic or functional reasons.

Conclusion

HDPE and Delrin both offer valuable capabilities for CNC machining, but they serve very different engineering purposes. HDPE is the best option for low-cost, chemically resistant, and flexible components, while Delrin is the preferred material for precision, strength, and wear resistance. Understanding the machining behaviors and material properties of each allows manufacturers and engineers to design parts that meet both performance and production requirements.

At SANS Machining, we have extensive experience machining both HDPE and Delrin. Whether you need a prototype gear in Acetal or a chemical-resistant tank plug in HDPE, our team can help evaluate your design for manufacturability (DFM).