CNC milling and laser cutting are two widely used manufacturing processes, each offering distinct advantages depending on part geometry, material type, and functional requirements. While both methods support precision manufacturing, they differ significantly in working principles, capabilities, and ideal applications. Understanding these differences helps engineers select the most efficient and cost-effective process for their projects.

Process Fundamentals

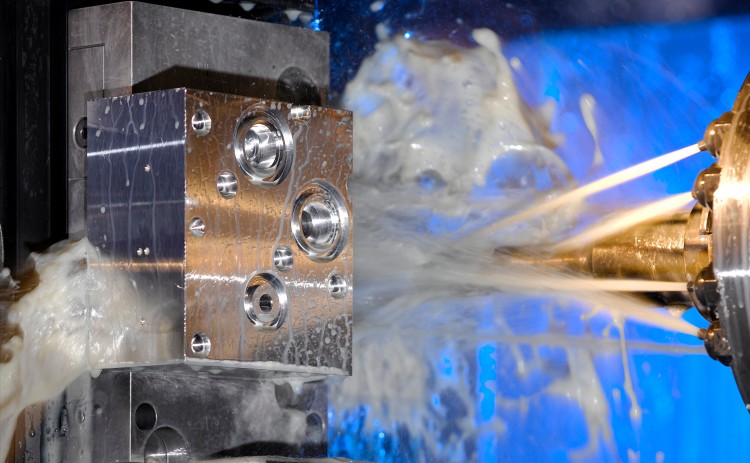

CNC milling is a subtractive machining process that uses rotating cutting tools to remove material from a solid workpiece. It produces three-dimensional features such as pockets, slots, contours, and complex surfaces. CNC milling supports a wide range of materials, including metals, plastics, and composites, and offers excellent dimensional control.

Laser cutting, by contrast, uses a focused laser beam to melt, burn, or vaporize material along a programmed path. It is primarily a two-dimensional cutting process and is commonly used to produce flat parts with precise outlines. Laser cutting delivers high speed and clean edges, especially for thin sheet materials.

Material and Thickness Capabilities

CNC milling handles a broader range of materials and thicknesses. It can machine thick blocks, hardened metals, and engineering plastics with tight tolerances. Milling also supports internal features and varying depths, making it suitable for structural and functional components.

Laser cutting performs best on thin sheet materials such as steel, aluminum, stainless steel, and non-metals like acrylic. As material thickness increases, cutting speed decreases, edge quality may decline, and heat-affected zones become more significant.

Design Flexibility and Geometry

CNC milling excels in producing complex three-dimensional geometries, including stepped features, angled surfaces, and internal cavities. It supports tight tolerances and high-precision features such as threads and bearing seats.

Laser cutting is ideal for intricate 2D profiles, sharp corners, and fine details in flat parts. However, it cannot create depth variations or internal 3D features without secondary operations.

Accuracy and Surface Quality

CNC milling provides excellent dimensional accuracy and surface finish when properly controlled. It allows fine tolerance adjustments and post-machining finishing if required.

Laser cutting delivers clean, burr-free edges but introduces thermal effects. The heat-affected zone may slightly alter material properties near the cut edge, which can be a concern for load-bearing or precision-critical applications.

Production Speed and Cost Considerations

Laser cutting offers fast setup and high cutting speed for flat parts, making it cost-effective for low to medium-volume production. Tool wear is minimal since no physical cutting occurs.

CNC milling involves longer setup times and tool management but offers greater versatility. It becomes more cost-effective for complex parts, thicker materials, or components requiring tight tolerances and multi-feature machining.

When CNC Milling Is the Preferred Choice

CNC milling is particularly well suited for manufacturing applications that demand high precision, structural complexity, and material flexibility. It is often selected when parts must meet strict dimensional tolerances or require multi-directional machining.

One of the key strengths of CNC milling lies in its ability to produce components with complex three-dimensional geometries. Parts that include pockets, slots, contours, angled surfaces, or multiple features on different faces can be accurately machined through coordinated multi-axis operations. This makes CNC milling ideal for functional components rather than purely decorative parts.

CNC milling is also the preferred solution when working with dense or hard materials. Metals such as carbon steel, stainless steel, titanium, and high-strength alloys require controlled cutting forces and stable tooling—capabilities that CNC milling machines are designed to handle. The process supports substantial material removal while maintaining precision and surface quality.

In product development stages, CNC milling plays a crucial role in prototyping. It allows engineers to create highly accurate prototypes that closely match final production parts, enabling effective testing, validation, and design refinement before mass production.

Additionally, CNC milling is widely used for custom tooling and specialized components. Fixtures, molds, jigs, and one-off mechanical parts often require tailored dimensions and tight tolerances, making CNC milling an essential process for custom manufacturing needs.

Overall, CNC milling excels in applications where accuracy, durability, and geometric complexity are critical to part performance.

When Laser Cutting Delivers Better Efficiency

Laser cutting is an ideal manufacturing method when speed, precision, and non-contact processing are the primary requirements. It is commonly chosen for applications involving thin materials and flat component designs.

This process is especially effective for producing intricate outlines, fine details, and complex 2D patterns. Decorative panels, enclosures, brackets, and sheet metal components with sharp corners or detailed cut paths can be produced with excellent edge quality and minimal post-processing.

Laser cutting is also highly efficient for high-speed production. For large batches of thin sheet materials, laser systems offer fast setup times and rapid cutting speeds, making them well suited for short lead times and high-throughput manufacturing environments.

Because laser cutting is a non-contact process, it is advantageous for materials that are sensitive to mechanical stress. Thin metals, delicate alloys, or materials prone to deformation benefit from the absence of cutting forces, reducing the risk of distortion during processing.

Consistency is another major advantage. Laser cutting provides uniform results across large production runs, ensuring repeatability and dimensional consistency without tool wear variations commonly seen in mechanical cutting processes.

Conclusion

CNC milling and laser cutting serve different roles in modern manufacturing. Milling offers flexibility, depth control, and precision for complex components, while laser cutting delivers speed and efficiency for flat parts. Selecting the right process depends on part design, material, tolerance requirements, and production goals. A clear understanding of each method ensures optimal performance and cost efficiency.