Grinding is a fundamental finishing process used to achieve precise dimensions, fine surface finishes, and tight tolerances in metal and hard material components. As industries demand higher efficiency and repeatability, CNC grinding has emerged as a preferred alternative to traditional manual grinding in many applications.

While both methods share the same purpose—removing material using abrasive wheels—the technology, precision, repeatability, and productivity vary significantly between them. This article explores the major differences between CNC grinding and traditional grinding, helping manufacturers understand when and why to choose one over the other.

What Is Traditional Grinding?

Traditional grinding refers to manual or semi-automated processes in which an operator uses a grinding machine—like a surface grinder or cylindrical grinder—and manually controls feed rates, wheel positioning, and part alignment.

Characteristics:

- Operator-dependent precision

- Suitable for small batches or custom work

- Requires skilled labor

- Lower initial investment

- Prone to human error and variation

This method is still common in tool rooms, prototyping shops, and small-scale operations where flexibility and one-off customization matter more than speed or automation.

What Is CNC Grinding?

CNC (Computer Numerical Control) grinding involves the use of CNC machines that automatically control the movement of grinding wheels along multiple axes. These machines follow programmed instructions to precisely shape or finish workpieces.

Features include:

- Multi-axis control (typically 2–5 axes)

- Automated toolpaths generated from CAD/CAM software

- Capable of complex geometries and multi-surface operations

- High repeatability and unattended operation

- Integrated probing and compensation systems

CNC grinding is widely used in aerospace, automotive, medical, and precision tool manufacturing.

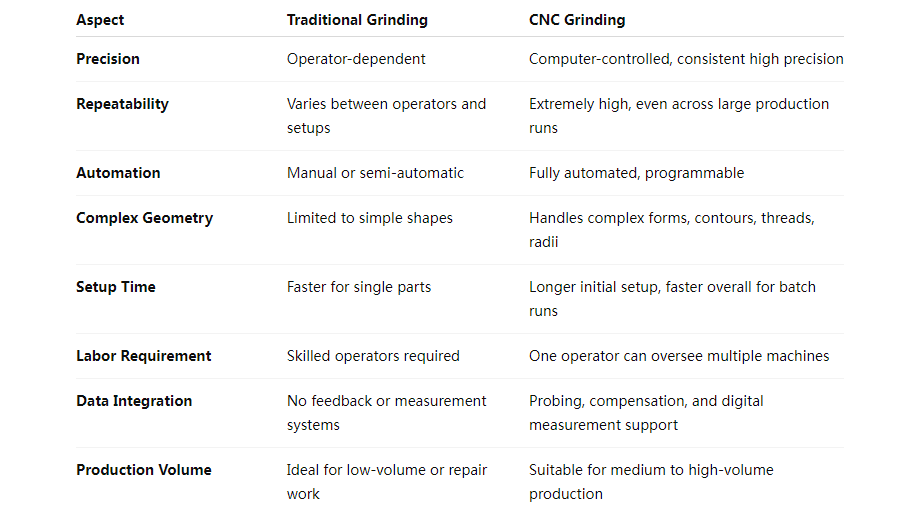

Key Differences Between CNC and Traditional Grinding

When to Choose Traditional Grinding

Despite being less automated, traditional grinding still has advantages in certain contexts:

- Low-volume production or one-off custom parts

- Manual touch-ups or regrinding worn components

- Prototyping where CAD/CAM files are not yet finalized

- Toolroom or maintenance applications

In these settings, the human touch and on-the-spot flexibility of traditional grinding can save time and reduce costs.

When CNC Grinding Offers a Competitive Edge

CNC grinding shines in high-precision, high-repetition environments where accuracy, efficiency, and documentation are critical:

- High-volume production of identical parts

- Tight tolerances, often in the micron range

- Complex profiles, such as gear flanks, cam lobes, medical implants

- Multi-operation workflows (OD, ID, face grinding in one setup)

- Quality traceability and digital integration with Industry 4.0 platforms

CNC systems also make it easier to implement statistical process control (SPC), reduce waste, and optimize tool usage through predictive maintenance.

Cost Considerations

Traditional grinding has lower upfront costs but higher long-term labor requirements. Tool wear is harder to monitor without automation, and quality may vary between operators.

CNC grinding involves higher machine investment and setup costs but offers significant savings over time through reduced scrap, faster cycle times, and minimal human error.

For businesses focused on scalability, repeatability, and consistent quality, CNC grinding typically offers a better return on investment.

Conclusion

While both CNC grinding and traditional grinding have their place in the machining world, they serve different priorities. Traditional grinding offers flexibility and human control for smaller or specialized jobs, while CNC grinding delivers speed, accuracy, and reliability in high-demand manufacturing environments.

Choosing the right method depends on your production volume, tolerance requirements, geometry complexity, and long-term business goals. For many companies, a hybrid approach—leveraging both traditional craftsmanship and modern automation—can provide the best of both worlds.