Steel is the backbone of modern industry, used in everything from infrastructure and transportation to consumer products and precision parts. Among the various steel types, carbon steel and stainless steel stand out as two of the most common and versatile materials. While they share iron as their primary element, the differences in their composition, mechanical performance, corrosion resistance, and applications are substantial.

Understanding the difference between carbon steel and stainless steel is crucial for project planning and determining steel procurement. This article will analyze the characteristics of carbon steel and stainless steel and provide a clear comparison.

Composition: The Root of Performance Differences

There are differences between carbon steel and stainless steel in terms of composition, corrosion resistance, and usage. Carbon steel is mainly composed of iron, carbon, and other elements, making it sturdy, durable, and cost-effective. However, without proper maintenance, carbon steel is prone to rusting and corrosion. In contrast, stainless steel contains chromium, which gives it excellent corrosion resistance due to the protective layer formed on its surface.

Carbon Steel Composition:

Carbon steel is primarily composed of iron and carbon. The amount of carbon added greatly influences the steel’s hardness, strength, and brittleness.

Low-carbon steel (up to 0.3% carbon): Also known as mild steel; easy to machine, weld, and form.

Medium-carbon steel (0.3%-0.6% carbon): Offers higher strength and hardness, suitable for structural components.

High-carbon steel (0.6%-1.5% carbon): Very hard and strong but less ductile, often used for tools, springs, and cutting edges.

Carbon steel contains minimal other alloying elements, which keeps costs low but reduces corrosion resistance.

Stainless Steel Composition:

Stainless steel includes at least 10.5% chromium, which allows it to form a protective chromium oxide layer that prevents corrosion. Other elements, such as nickel, molybdenum, manganese, and nitrogen, are often added to enhance corrosion resistance, strength, or workability.

Austenitic Stainless Steel (e.g., 304, 316): Non-magnetic, excellent corrosion resistance, highly formable.

Martensitic Stainless Steel (e.g., 410, 420): Magnetic, can be hardened by heat treatment, moderate corrosion resistance.

Ferritic Stainless Steel (e.g., 430): Magnetic, lower cost, good corrosion resistance, used in decorative applications.

Corrosion Resistance: A Major Divider

The chemical composition of carbon steel and stainless steel determines significant differences in their corrosion resistance. For example, the chromium content of stainless steel exceeds 10.5%, which allows it to form a passive oxide layer, roughly equivalent to what is commonly referred to as stainless steel. This passivation layer protects the underlying metal in a corrosive environment rich in moisture, salt, or acidic compounds, minimizing corrosion to the greatest extent possible. 304 and 316 austenitic stainless steels are a good example, which have been proven to withstand atmospheric and water corrosion. 316 austenitic stainless steel is also known for its resistance to chloride corrosion, making it the preferred choice for marine and industrial applications.

Although stainless steel has excellent corrosion resistance, carbon steel is still widely used due to its ease of availability. However, due to the lack of chromium, carbon steel is more susceptible to the effects of moisture and air. Unlike stainless steel, carbon steel does not contain a protective oxide layer, making it prone to corrosion and rapidly deteriorating over time. In order to improve the corrosion resistance of carbon steel, surface treatment is usually carried out by painting or galvanizing. Although these methods do help reduce corrosion, they only apply to the surface and must be reprocessed frequently.

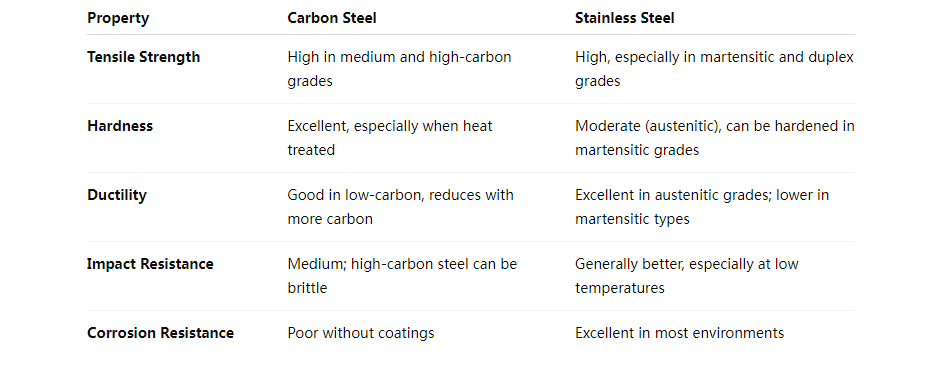

Mechanical Properties: Strength vs. Ductility

There are significant differences in mechanical properties between stainless steel and carbon steel. Stainless steel has higher ductility and toughness, making it more suitable for impact resistance and deformation. In addition, it can maintain its strength and performance over a wider temperature range. On the contrary, carbon steel welds have higher tensile strength and hardness due to their higher carbon content. This makes it easier to apply to structural applications that require rigidity and load-bearing capacity. However, the decrease in ductility makes it impossible for carbon steel to withstand stress without fracture. The selection of these materials depends on the specific mechanical properties required for the application.

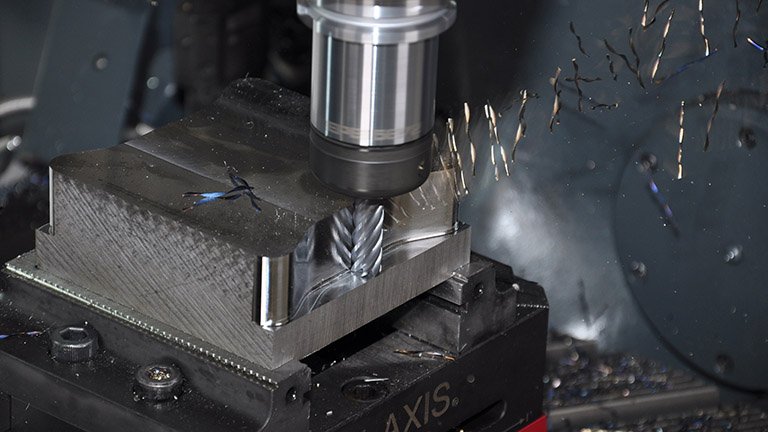

Machining Performance: Processing Considerations

Carbon Steel:

- Low-carbon steel machines easily.

- Higher-carbon grades require sharper tools and controlled speeds to avoid rapid tool wear.

- Generally less tool wear and faster cycle times than stainless steel.

Stainless Steel:

- Austenitic grades (e.g., 304, 316) are more challenging to machine due to work hardening.

- Specialized tooling (coated carbide, advanced inserts) and coolant are necessary.

- Machining speed is slower, but modern CNC processes handle these materials effectively.

If ease of machining and lower production costs are key, carbon steel is favorable. For corrosion-resistant precision parts, stainless steel remains competitive despite longer machining times.

Cost Considerations: Budget vs. Longevity

Carbon Steel:

Lower raw material cost.

Lower energy and tooling costs during production.

May require protective treatments (e.g., painting, galvanizing) which can increase total lifecycle cost.

Stainless Steel:

Higher upfront material cost.

Requires slower machining speeds, increasing labor and machining expenses.

Lower maintenance cost over product life due to its resistance to rust, staining, and degradation.

Which type of steel is more suitable for manufacturing mechanical components?

The multifunctionality of carbon steel in machinery

Carbon steel is highly suitable for manufacturing mechanical components due to its strength, durability, and versatility. It has good processability and its mechanical properties can be adjusted through heat treatment, making it very useful in many different industries. In addition, its price is lower than other metals, making it an ideal choice for industries that require high productivity without sacrificing quality or efficiency. Correctly selecting materials in carbon steel grades can ensure the optimal combination of hardness, wear resistance, and tensile strength required for specific machinery.

Why stainless steel is the preferred material for certain mechanical parts

For certain mechanical parts, stainless steel is highly favored due to its excellent corrosion resistance, ensuring a long service life even under harsh conditions. In addition, its durability enables it to withstand high temperatures and extreme wear and tear. The sanitary properties and extremely low maintenance requirements of stainless steel also make it highly beneficial for applications in food processing, medical equipment, and chemical industries. The strength and deformation resistance of this alloy enable it to be reliably applied to major mechanical parts under harsh operating requirements.

Conclusion

Both carbon steel and stainless steel are essential materials in modern manufacturing, each with unique strengths and limitations:

Choose carbon steel when you need high strength, easy machinability, and cost-effectiveness in dry or protected environments.

Opt for stainless steel when you require excellent corrosion resistance, long-term durability, and lower maintenance, even if upfront costs are higher.

Selecting the right steel depends on the application’s demands for strength, corrosion resistance, appearance, and budget. For complex decisions or customized steel parts, consulting with an experienced manufacturer ensures optimal material selection.