Author Archives: sansmachining

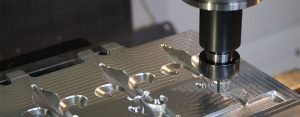

CNC Milling vs. Laser Cutting: Choosing the Right Manufacturing Process

CNC milling and laser cutting are two widely used manufacturing processes, each offering distinct advantages [...]

Feb

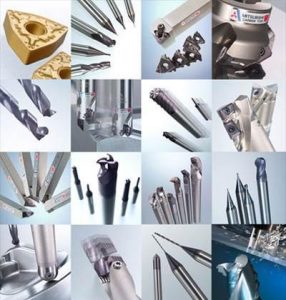

The Importance of Tooling Design Services in Precision Machining

Tooling design services play a critical role in translating engineering intent into reliable, production-ready manufacturing [...]

Feb

A Practical Guide to Blind Holes in Machining

Improper blind hole specifications can lead to tool breakage, poor thread quality, excessive machining time, [...]

Jan

Hardness Selection Guide for CNC Machining

Choosing a material that is too hard can increase machining difficulty and cost, while selecting [...]

Jan

Welding vs. Soldering: Key Differences, Applications, and Selection Guidelines

Among the many joining methods available, welding and soldering are two of the most commonly [...]

Jan

Why Purchasers and Engineers Sometimes Prefer Small Machining Shops Over Large Companies

In real sourcing and engineering practice, many purchasers and engineers find themselves repeatedly choosing smaller [...]

Jan

Surface Roughness vs. Surface Finish: Understanding the Difference in CNC Machining

Surface Roughness vs. Surface Finish, explains what each term means, how they are measured, and [...]

Jan

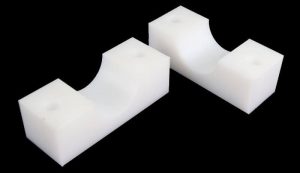

HDPE vs. Delrin Which Plastic is Right for Your CNC Machining Project

Break down the differences between HDPE and Delrin, focusing on their machinability, mechanical properties, and [...]

Jan

Low-Volume, High-Mix Machining: Meeting Modern Manufacturing Demands

Low-volume, high-mix machining become a critical capability for industries seeking agility without sacrificing precision or [...]

Jan

DLC Coating for CNC Machined Parts

As industries continue to demand lighter, faster, and more efficient mechanical systems, DLC coating has [...]

Jan

Drawing Notes for Blind Hole Design: Inspection Challenges and Practical Solutions

Blind holes are widely used in machined components where structural integrity, sealing, or assembly requirements [...]

Jan

HDPE vs. PET in Manufacturing

HDPE and PET stand out as two versatile materials that serve a wide range of [...]

Dec

Material Hardness Analysis in Manufacturing and Machining

Without a proper understanding of hardness, even well-designed parts can fail prematurely or become difficult [...]

Dec

OEM, ODM, and JDM In Modern Manufacturing

Three major collaboration models—OEM, ODM, and JDM—define how a product moves from concept to market.

Dec

Aging In Heat Treatment: Mechanisms, Types, And Industrial Importance

This guide explores the science behind aging, the difference between natural and artificial processes, and [...]

Dec

Exploring Magnetic Properties in CNC Machined Parts and the Importance of Demagnetization Services

Understanding how magnetism develops during machining—and why demagnetization services are essential—helps engineers ensure their parts [...]

Dec

Electroplated CNC Machining Parts: Enhancing Performance, Durability, and Aesthetics

This article explores the principles, benefits, materials, and applications of electroplated CNC machined parts, along [...]

Dec

Stress Relief Strategies in CNC Machining

Understanding and controlling internal stress is therefore crucial to maintaining the accuracy, reliability, and longevity [...]

Dec