In the vast world of ferrous metals, the category of “steel” is incredibly diverse. While carbon steel forms the versatile backbone of the industry, many applications demand performance characteristics that carbon alone cannot provide. This is where low alloy steel comes in—a sophisticated class of materials engineered to deliver significantly enhanced mechanical properties with only minor additions of alloying elements.

Low alloy steel represents a critical bridge between the economy of carbon steel and the specialized, high-cost performance of high alloy steels like stainless or tool steels. This article provides a comprehensive overview of what defines low alloy steel, the key types, and why it is an essential material in modern engineering.

What is Low Alloy Steel?

Low alloy steel is a category of steel that is alloyed with a variety of elements to improve its mechanical properties. The defining characteristic is the total weight percentage of these alloying elements. While there are slight variations in formal definitions, a material is generally classified as low alloy steel when the total alloying content is between 1.5% and 5% by weight.

Unlike carbon steel, where carbon is the primary alloying and hardening agent, low alloy steels intentionally include elements such as chromium, molybdenum, nickel, manganese, vanadium, and silicon. The magic of low alloy steel is that these small, precisely controlled additions can produce dramatic improvements in properties like:

- Strength and Hardness: Achieving higher strength levels than is possible with plain carbon steel.

- Toughness: Resisting fracture and absorbing impact, especially at low temperatures.

- Weldability: Maintaining strength and integrity in and around welded joints.

- Wear Resistance:Withstanding abrasion, erosion, and friction.

- Corrosion Resistance: Offering better performance against atmospheric corrosion than carbon steel.

- High-Temperature Strength (Creep Resistance): Retaining strength and stability at elevated temperatures.

Major Categories of Low Alloy Steel

Low alloy steels are often grouped by their primary alloying elements or the specific properties they are designed to exhibit.

1. High-Strength Low-Alloy (HSLA) Steel

HSLA steels are perhaps the most economically significant category of low alloy steels. They are not defined by their specific chemical composition but rather by their superior mechanical properties, which are achieved with very small alloy additions (typically less than 2%). The goal of HSLA steel is to provide a higher strength-to-weight ratio than carbon steel without the high cost of more heavily alloyed materials. This is accomplished through a combination of micro-alloying with elements like vanadium, titanium, and niobium, along with controlled thermomechanical processing during manufacturing.

Key Properties: Excellent strength combined with good toughness and formability. Crucially, they are designed to be highly weldable.

Common Grades: ASTM A572, A656, A709.

Typical Applications: Automotive frames and components, bridges, heavy construction equipment (bulldozers, cranes), oil and gas pipelines, and structural applications where reducing weight without sacrificing strength is critical.

2. Chromium-Molybdenum (Chrome-Moly) Steel

As the name suggests, the primary alloying elements in this group are chromium and molybdenum. This combination produces a steel with an exceptional balance of strength, toughness, and high-temperature performance. Chrome-moly steels are highly responsive to heat treatment, allowing their properties to be tailored for very demanding applications.

Key Properties: Excellent hardness and strength, good fatigue resistance, and the ability to retain strength at elevated temperatures. The chromium content also provides a slight improvement in corrosion resistance over carbon steel.

Common Grades: 4130, 4140, 4150 (AISI/SAE classification), A387 (for pressure vessels).

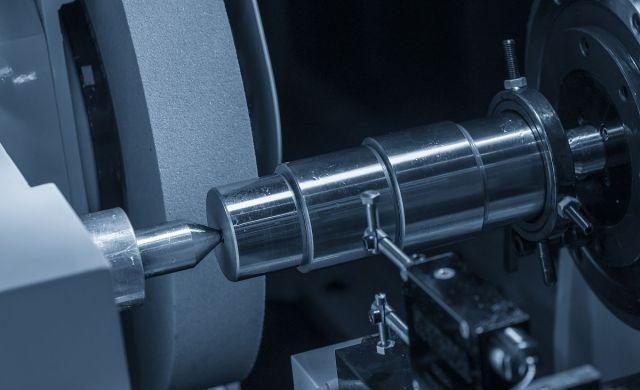

Typical Applications: High-performance automotive and aerospace components (crankshafts, connecting rods, roll cages), pressure vessels for power plants and refineries, high-pressure tubing, and industrial gears and shafts.

3. Weathering Steels (e.g., Corten)

Weathering steels are a unique subset of low alloy steels designed to exhibit superior atmospheric corrosion resistance. They contain a small amount of copper, chromium, and nickel. When exposed to the elements, these steels form a stable, rust-like oxide layer (patina) on their surface. This patina acts as a protective barrier, regenerating itself over time and dramatically slowing the rate of further corrosion, thus eliminating the need for paint or other protective coatings.

Key Properties: Excellent atmospheric corrosion resistance, good strength, and a distinctive, aesthetically pleasing appearance.

Common Grades: ASTM A588, A242, A606-4 (often sold under the trade name COR-TEN®).

Typical Applications: Outdoor sculptures, architectural facades, bridges, and structural components in environments where maintenance and painting are difficult or undesirable.

4. Nickel-Alloy Steels

When superior toughness and impact strength are the primary requirements, especially at low temperatures, nickel is the alloying element of choice. Low alloy steels containing 2% to 5% nickel exhibit exceptional resistance to brittle fracture.

Key Properties: High toughness and ductility, even at sub-zero temperatures.

Typical Applications: Gears, drive shafts, and critical machine components subjected to high shock loads, also used in cryogenic applications.

Processing and Fabrication Considerations

Working with low alloy steels requires a greater degree of control compared to plain carbon steels.

Heat Treatment: The majority of low alloy steels are designed to be heat-treated (quenched and tempered) to develop their optimal properties. The presence of alloys increases their “hardenability,” meaning they can be hardened more deeply and uniformly through a thicker cross-section than carbon steel.

Weldability: While many grades (especially HSLA) are designed for good weldability, others can be challenging. Higher-strength grades often require special welding procedures, including preheating the material before welding and applying a post-weld heat treatment (PWHT) to relieve stresses and prevent cracking in the heat-affected zone (HAZ).

Conclusion

Low alloy steel stands as a testament to the power of metallurgical precision. By adding just a small percentage of carefully selected elements, the fundamental properties of steel can be elevated to meet a vast range of demanding engineering challenges. From the lightweight strength of a skyscraper’s frame to the heat-resistant integrity of a pressure vessel and the rugged durability of mining equipment, low alloy steels provide a critical combination of performance, processability, and economic value that continues to drive innovation across all sectors of industry.