In today’s fast-paced manufacturing landscape, product development cycles are shorter than ever. Businesses are under constant pressure to bring new products to market faster, reduce costs, and maintain high-quality standards. One of the key technologies enabling this speed and flexibility is Rapid Tooling — a process that bridges the gap between prototyping and full-scale production.

What Is Rapid Tooling?

Rapid tooling refers to the process of quickly producing molds and tools for manufacturing. It is a critical component of the rapid manufacturing methodology, enabling faster and more efficient production of functional parts and prototypes. Rapid tooling plays a crucial role in bridging the gap between rapid prototyping and conventional tooling methods, providing a cost-effective and time-saving solution.

The primary objective of rapid tooling is to accelerate the mold production workflow, allowing manufacturers to quickly transition from the design phase to the actual manufacturing stage. By leveraging advanced technologies such as additive manufacturing and CNC machining, rapid tooling facilitates the fabrication of molds and tools with higher precision and shorter lead times.

It is typically used for:

- Prototype molds for testing design and functionality

- Bridge tooling for low- to medium-volume production before full-scale manufacturing

- Custom tooling for specialized or short-run components

In essence, rapid tooling provides a cost-effective and time-efficient solution for verifying part designs, testing materials, and producing early samples without the expense and delay of traditional tooling methods.

The Process of Rapid Tooling

The process combines digital manufacturing technologies such as CNC machining, 3D printing, and hybrid fabrication to create molds or dies faster than traditional toolmaking.

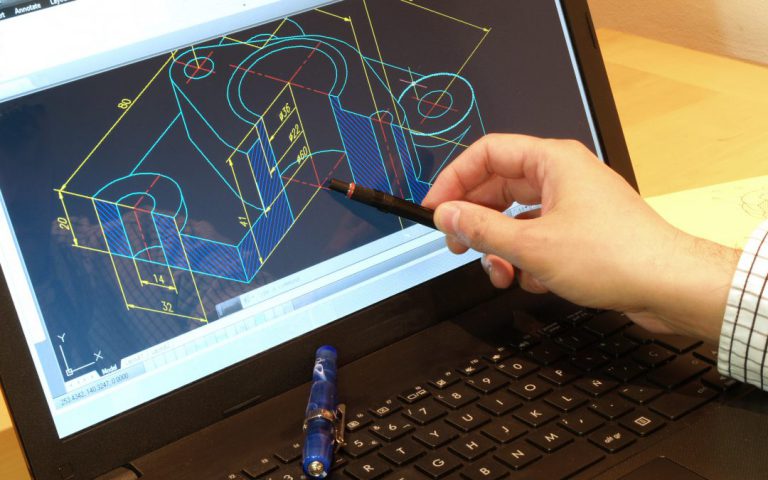

Step 1: Design and CAD Modeling

The process begins with a 3D CAD model of the desired part or tool. Engineers optimize the design for manufacturability, considering factors such as draft angles, parting lines, and cooling channels.

Step 2: Tool Fabrication

The tooling is manufactured using fast, precise methods such as:

CNC machining: Ideal for metal tooling, offering accuracy and strength.

Additive manufacturing (3D printing): Used for plastic or metal inserts, complex geometries, or hybrid molds.

Casting or epoxy tooling: Used for short-run prototype molds at lower cost.

Step 3: Testing and Validation

Once the tool is made, it is tested under real production conditions to evaluate its performance. Adjustments are made if necessary to improve durability, accuracy, or surface finish.

Step 4: Production

After validation, the tool is ready for limited production runs. Depending on the method and material, a rapid tool may produce a few dozen to several thousand parts before replacement or modification is needed.

Types of Rapid Tooling

Rapid tooling can be categorized based on its purpose and manufacturing approach:

(1) Direct Rapid Tooling

In direct methods, the tooling (e.g., mold or die) is produced directly from digital data using additive manufacturing or CNC machining — without requiring a master pattern.

Advantages: Shorter lead time, reduced labor, and direct design iteration.

(2) Indirect Rapid Tooling

Here, a master pattern is created first (e.g., via 3D printing), which is then used to cast or replicate the actual mold using materials like epoxy or silicone.

Advantages: Lower cost, suitable for prototyping and low-volume runs.

Both types can be integrated with conventional mold bases or inserts, providing flexibility for a wide range of applications.

Materials Used in Rapid Tooling

Rapid prototype molds are temporary tools utilized for producing prototypes, small-batch parts, or cast resins. Some commonly used materials for rapid prototyping molds include silicone rubber, polyurethane, gypsum, and metals.

Aluminum

Aluminum is a preferred material for rapid tooling due to its excellent thermal conductivity, making it highly suitable for injection molding processes. Aluminum is readily accessible and offers a good strength-to-weight ratio.

Steel

Steel, particularly tool steel, is a reliable choice for rapid machining. It is durable and capable of withstanding high-pressure molding processes. China’s steel industry ensures a stable supply of high-quality material.

Plastics

For certain low-volume applications, plastics such as ABS or Nylon can be used for rapid tooling. These materials are cost-effective and are ideal for prototyping needs.

Copper

Copper is used in certain specialized applications, particularly for electronic components. It offers excellent electrical conductivity and is easy to machine.

Applications of Rapid Tooling

Rapid tooling is widely adopted across multiple industries, including:

- Automotive: For testing components like housings, connectors, and brackets before mass production.

- Medical Devices: Producing FDA-compliant prototype molds for testing biocompatible materials.

- Aerospace: Fabricating lightweight tooling for composite part production.

- Consumer Electronics: Accelerating the prototyping of casings and internal components.

- Industrial Manufacturing: Creating jigs, fixtures, and low-volume replacement parts.

By reducing the time between concept and production, rapid tooling helps manufacturers stay competitive in markets where innovation speed is critical.

The Importance of Rapid Tooling

Faster Time-to-Market: The accelerated production speed of rapid tooling, compared to conventional methods, significantly shortens the overall time required for product development and manufacturing.

Cost Savings: Rapid tooling is more cost-effective than traditional molding methods, particularly for low-volume production or prototyping, as it eliminates the need for complex and expensive high-cavitation steel tooling.

Design Flexibility: Rapid tooling facilitates easy design modifications or improvements during the mold production process, allowing for higher flexibility and faster design iterations.

Enhanced Efficiency: By shortening the cycle time from design completion to production, rapid tooling streamlines the manufacturing workflow, thus accelerating the product launch timeline.

Customization and Complexity: Rapid tooling technologies, such as additive manufacturing, enable the creation of complex geometries and custom mold designs that would be either difficult or prohibitively expensive to achieve using conventional methods.

The Future of Rapid Tooling

With advancements in additive manufacturing, hybrid machining, and digital simulation, the future of rapid tooling is more promising than ever.

Emerging technologies such as conformal cooling channels, metal 3D printing, and AI-driven mold design are making tools faster to produce, more durable, and more efficient in heat transfer.

As digital manufacturing ecosystems mature, rapid tooling will continue to play a vital role in shortening design cycles, reducing costs, and enabling mass customization across industries.

Conclusion

Rapid Tooling has become a cornerstone of modern manufacturing innovation. It bridges the gap between prototyping and full-scale production, offering manufacturers the agility to test, iterate, and deliver products faster than ever before.

By combining CNC precision, additive flexibility, and smart material selection, rapid tooling provides the perfect balance between speed, cost, and performance — empowering companies to stay ahead in a competitive global market.