Material hardness is one of the most fundamental mechanical properties in engineering and manufacturing. It directly influences how a material responds to external forces such as cutting, wear, indentation, and deformation. In machining and product design, hardness analysis helps engineers predict tool wear, select suitable cutting parameters, and ensure that finished components meet functional and durability requirements. Without a proper understanding of hardness, even well-designed parts can fail prematurely or become difficult and costly to manufacture.

What Is Material Hardness?

Material hardness describes a material’s resistance to permanent surface deformation. In practical terms, it reflects how well a material resists scratching, indentation, or abrasion. Hardness does not represent a single property but rather a response to localized stress, making it closely related to strength, wear resistance, and microstructure.

Harder materials generally provide better wear resistance and longer service life, especially in contact-heavy or abrasive environments. However, increased hardness often comes at the cost of reduced ductility, which can make materials more brittle and challenging to machine. This trade-off makes hardness analysis an essential step in material selection.

Common Hardness Testing Methods

Different hardness testing methods exist to evaluate materials across various scales and applications. Each method applies a controlled force and measures the resulting indentation.

Rockwell hardness testing is widely used in industrial environments due to its speed and simplicity. It measures the depth of penetration under load and is suitable for metals with a broad range of hardness levels.

Brinell hardness testing uses a larger indenter and is ideal for castings and materials with coarse grain structures. It provides an average hardness value over a larger surface area.

Vickers hardness testing offers high accuracy and works well for thin materials, surface treatments, and microstructural analysis. It is frequently used in research and quality inspection.

Shore hardness testing applies primarily to elastomers and plastics, where resistance to indentation rather than metal deformation is the key factor.

How To Choose The Right Hardness Test Method

Analyze the core elements of testing method selection from different dimensions to help you make scientific judgments in design review, incoming inspection, or heat treatment verification. Mastering these principles can effectively improve testing efficiency and reduce error disputes.

Workpiece size and material type

In practical applications, the main basis for determining hardness testing methods is the size and material type of the workpiece. For large forged bearings or mold steel blocks, Brinell hardness testing is more suitable because it uses larger steel ball indenters, which can more accurately reflect the overall compressive performance of the material. However, if you are facing thin-walled stainless steel snap springs or small aluminum alloy parts, the Brinell test may appear “too rough”, and in this case, Rockwell or Vickers hardness testing should be used.

The type of material can also affect the selection. Soft metals such as aluminum and copper are suitable for using HRB or HV, while high hardness materials such as hard alloys and ceramics typically use Vickers or microhardness methods. For polymers or composite materials, conventional hardness testing may not even be applicable. In this case, specialized instruments or Shore hardness should be used to evaluate its elasticity.

Surface Roughness And Treatment

For workpieces with coatings, heat treatment layers, or nitriding layers, it is recommended to use a microhardness tester with high surface sensitivity (such as a Vickers hardness tester or a Knoop hardness tester) and accurately locate the test points on the metallographic section. If it is a rough machined surface, especially for castings, forgings, or unpolished parts, Brinell hardness (HB) is the most durable and stable testing method.

Application Industries

The industry determines the testing accuracy and also determines the range of technical choices for testing methods.

In the aerospace industry, almost all load-bearing structural components must undergo Rockwell hardness HRC testing after heat treatment, with an accuracy requirement of ± 1HRC. Many components also require metallographic structure evaluation.

The medical device industry pays more attention to the uniformity of material surface hardness.

The mold industry pursues overall material performance that is both hard and tough, requiring high HRC hardness and materials that are not easily brittle. Usually, after quenching and tempering, the overall evaluation is carried out using Brinell hardness HB or Rockwell hardness HRC. High end molds also require multi-point microhardness distribution scanning of the cavity area.

Hardness Test After Heat Treatment

The hardness change after material heat treatment is the most significant and also one of the most concerned indicators for customers. Different processing techniques correspond to different testing plans.

For example, the thickness of the carburized layer is usually only 0.8-1.2mm, and traditional HRC hardness testing can easily penetrate the surface layer and measure the substrate. In this case, we will use HV or Knoop microhardness testing to perform gradient scanning on the slices, measuring every 0.1mm from the surface to the center, and drawing a complete hardness distribution curve.

If it is a whole quenching and tempering treatment (such as H13, SKD11 and other tool steels), HRC or HB hardness tester is usually used for large-area rapid measurement, which is efficient and suitable for batch testing.

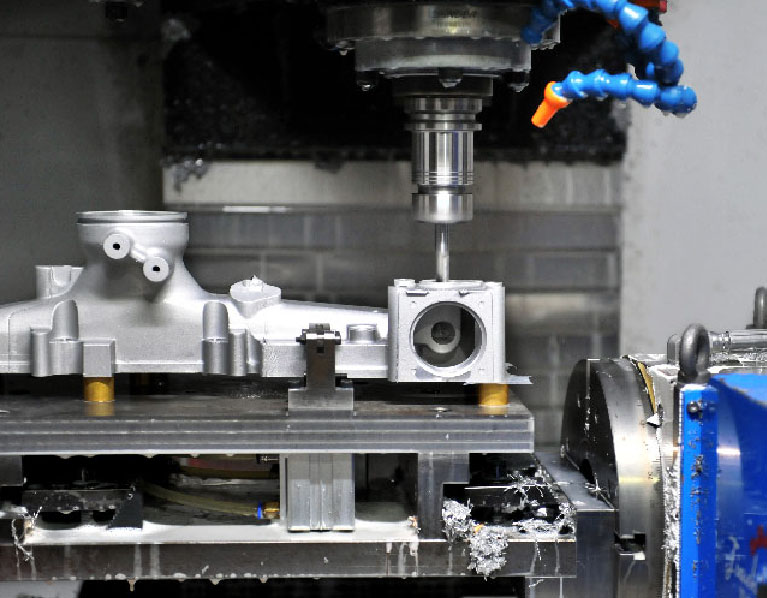

Hardness and Its Impact on Machining

Hardness has a direct effect on machinability. As hardness increases, cutting forces rise, tool wear accelerates, and heat generation becomes more difficult to control. Hard materials such as hardened steels or superalloys require specialized tooling, coatings, and reduced cutting speeds to maintain dimensional accuracy.

Softer materials, while easier to cut, may present their own challenges. Excessive softness can lead to material smearing, poor surface finish, and dimensional instability. This is common when machining annealed metals or certain plastics. A balanced hardness level often provides the best compromise between machinability and performance.

Understanding hardness values allows machinists to optimize tool selection, feed rates, and cooling strategies, reducing scrap and improving productivity.

Relationship Between Hardness and Other Mechanical Properties

Although hardness often correlates with tensile strength and wear resistance, it does not provide a complete picture of material behavior. A very hard material may resist surface damage but fail under impact or cyclic loading. Conversely, a slightly softer material may absorb energy more effectively and perform better in dynamic environments.

Hardness analysis should therefore be combined with other mechanical tests such as tensile testing, impact testing, and fatigue analysis. Together, these evaluations offer a more reliable assessment of material performance in real-world applications.

Hardness Control Through Heat Treatment

Heat treatment plays a critical role in adjusting material hardness. Processes such as quenching, tempering, annealing, and aging allow manufacturers to tailor hardness levels to specific applications. For example, increasing hardness through quenching improves wear resistance, while tempering restores toughness and reduces brittleness.

In CNC machining, components are often machined in a softer state and then heat-treated to achieve final hardness. This approach simplifies machining while ensuring that the finished part meets performance requirements.

Conclusion

Material hardness analysis is a cornerstone of modern manufacturing and machining. It influences material selection, machining strategy, heat treatment planning, and long-term product performance. By understanding hardness and its limitations, engineers and manufacturers can make informed decisions that improve quality, reduce costs, and extend component life. In an environment where precision and reliability are critical, hardness analysis remains an indispensable tool for achieving consistent and high-performing results.