In modern manufacturing and product design, High-Density Polyethylene (HDPE) has become one of the most versatile and valuable engineering plastics. As industries shift toward lighter, corrosion-resistant, and cost-effective materials, HDPE is increasingly replacing traditional metals in applications ranging from CNC machined components to piping, enclosures, and industrial fixtures.

While metals like aluminum, steel, and brass have long been the backbone of mechanical production, HDPE offers a unique combination of performance, machinability, and economic advantages that make it a superior choice in many scenarios. This article explores the key reasons why HDPE often outperforms metals in today’s manufacturing environment.

1. Lightweight Yet Durable

One of the most notable advantages of HDPE is its low density, approximately 0.95 g/cm³, which is less than one-seventh the density of steel and about one-third that of aluminum. This significant weight reduction translates to easier handling, lower transportation costs, and improved efficiency in assembly.

Despite being lightweight, HDPE offers excellent strength-to-weight ratio. It can withstand moderate mechanical stress, impact, and abrasion, making it suitable for many structural and protective applications where weight reduction is critical — such as marine components, machine guards, and industrial panels.

2. Superior Corrosion and Chemical Resistance

Unlike metals that can oxidize, rust, or corrode over time when exposed to moisture or chemicals, HDPE is inherently resistant to corrosion. It does not react with most acids, bases, or organic solvents, making it ideal for environments where chemical exposure is frequent — such as laboratories, wastewater systems, and food processing facilities.

For example:

- Steel requires coatings or galvanization to resist corrosion.

- Aluminum can corrode in saline environments without anodizing.

- HDPE, however, resists corrosion naturally, without the need for surface treatment or maintenance coatings.

This resistance greatly enhances product longevity and reduces maintenance costs.

3. Cost-Effectiveness and Ease of Machining

From a manufacturing standpoint, HDPE is highly cost-effective. Its raw material cost is significantly lower than most metals, and it is easier and faster to machine.

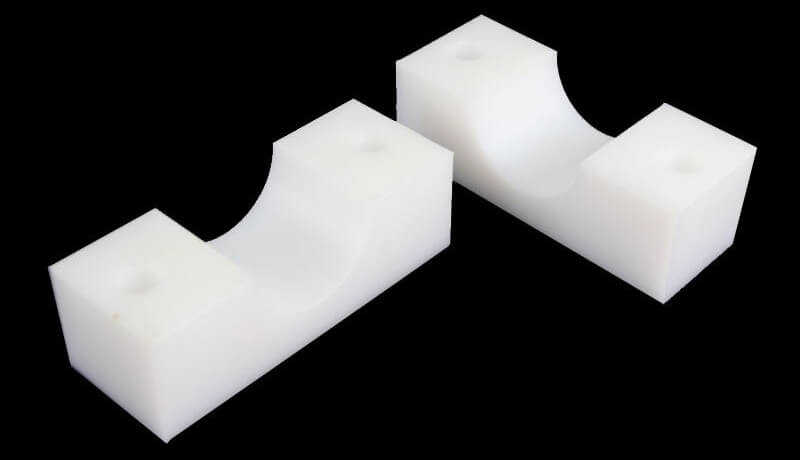

HDPE cuts smoothly on CNC mills and lathes, requiring less power, lower tool wear, and shorter cycle times. It also allows for high feed rates and does not require lubricants during machining, which simplifies the process and reduces environmental impact.

Additionally, HDPE can be easily welded, thermoformed, or fabricated, offering flexibility that metals often cannot match without costly secondary operations.

4. Excellent Impact and Wear Resistance

HDPE exhibits exceptional impact strength even at low temperatures, unlike some metals that may become brittle in cold environments. This property makes it ideal for outdoor and industrial applications where parts may experience frequent impacts, vibrations, or shocks.

Its low friction coefficient also provides superior wear performance, especially in dynamic assemblies or sliding components. For example, HDPE bushings, spacers, or liners can operate smoothly without lubrication — reducing maintenance and energy consumption compared to metal alternatives.

5. Electrical and Thermal Insulation

Metals are inherently conductive, which limits their use in electrical and thermal insulation applications. HDPE, on the other hand, is a non-conductive material, making it an excellent insulator for:

- Electrical housings and covers

- Circuit board supports

- Cable management systems

- Safety enclosures around electronic equipment

Moreover, HDPE’s low thermal conductivity helps maintain temperature stability in sensitive assemblies, reducing the risk of heat transfer or short circuits.

6. Moisture Resistance and Dimensional Stability

HDPE has extremely low moisture absorption, meaning it retains its dimensional stability even in humid or submerged environments. This is in stark contrast to metals, which can expand, oxidize, or degrade when exposed to moisture.

This property is particularly valuable for marine, outdoor, and fluid-handling systems, where HDPE parts maintain their structural integrity and functionality over long periods without corrosion or swelling.

7. Environmental Sustainability and Recyclability

In addition to its performance benefits, HDPE supports sustainable manufacturing goals. It is 100% recyclable and can be reprocessed multiple times without significant loss of properties. Recycled HDPE is widely used in packaging, industrial products, and construction materials.

Furthermore, because it does not require energy-intensive mining or refining like metals do, HDPE offers a smaller carbon footprint throughout its lifecycle — from production to disposal.

8. Noise and Vibration Dampening

Another overlooked advantage of HDPE is its ability to absorb sound and vibration. Metal components tend to transmit noise and mechanical vibration, which can lead to discomfort or fatigue in machinery and structures. HDPE, being a polymer, naturally dampens vibrations, improving both performance and user experience in environments like manufacturing plants and transportation systems.

9. Applications Where HDPE Replaces Metal

- HDPE has found success in replacing metal in a wide range of industries, such as:

- Machinery & Equipment: Guards, spacers, wear strips, and conveyor components.

- Marine & Outdoor Use: Boat parts, docks, and weather-resistant fittings.

- Chemical Processing: Tanks, piping systems, and chemical-resistant trays.

- Food Industry: Cutting boards, liners, and FDA-compliant contact surfaces.

- Electrical Engineering: Insulating panels and protective enclosures.

Its balance of machinability, resistance, and cost efficiency makes it a top choice where metals would otherwise be overengineered or too expensive.

10. When to Choose Metal Over HDPE

While HDPE offers numerous benefits, it’s not always a perfect replacement for metals. For example:

- Applications requiring very high strength, stiffness, or heat resistance still favor metals such as stainless steel or titanium.

- HDPE’s maximum service temperature (around 120°C) limits its use in high-heat environments.

- Its lower rigidity may require thicker sections for structural applications.

Thus, the choice between HDPE and metal should always consider mechanical, thermal, and cost-performance balance.

Conclusion

The growing adoption of HDPE in precision machining and industrial design marks a shift toward smarter, more sustainable engineering. Its combination of light weight, corrosion resistance, machinability, and cost-effectiveness provides compelling advantages over traditional metals in many applications.

For designers and manufacturers seeking durable, economical, and eco-friendly materials, HDPE stands out as a modern engineering solution — one that redefines performance without compromising precision or reliability.